Sliding joints of trestle outriggers

A technology of nodes and trestles, which is applied in the field of sliding nodes of trestle legs, can solve problems such as damage to coal conveying trestles or transfer stations, hidden dangers in connection methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to make the technical solutions and advantages of the present invention clearer, the embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

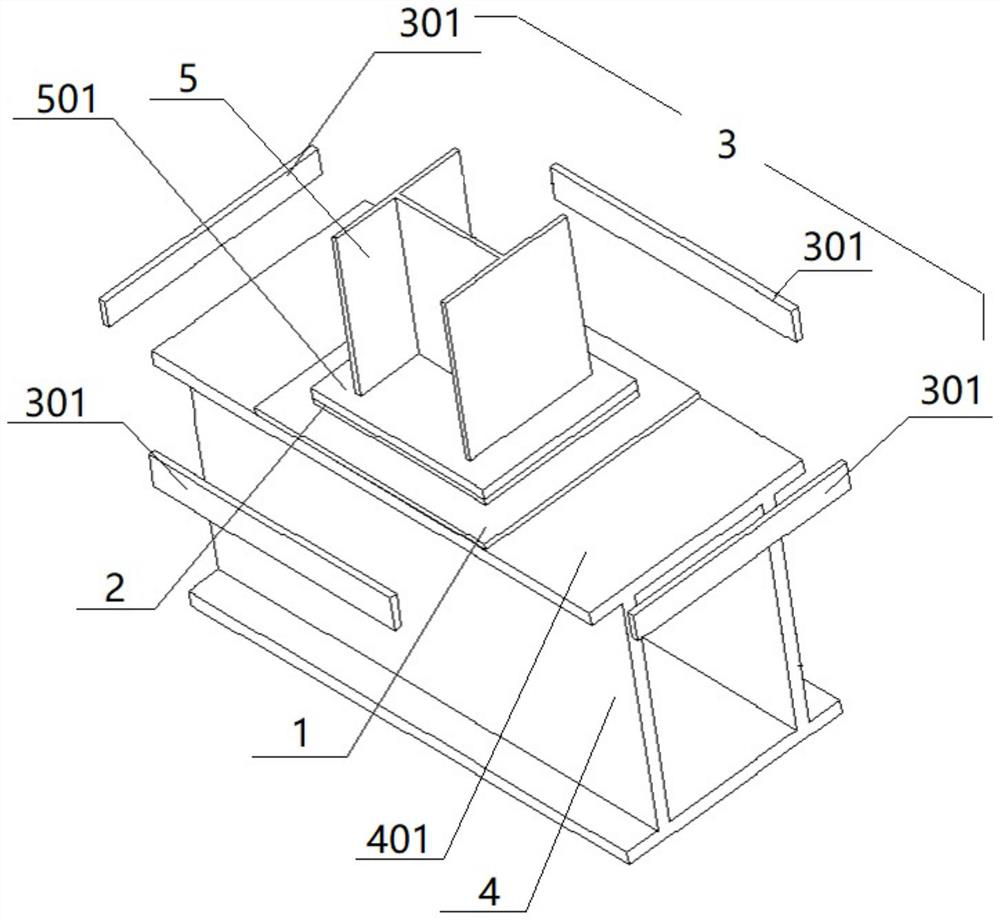

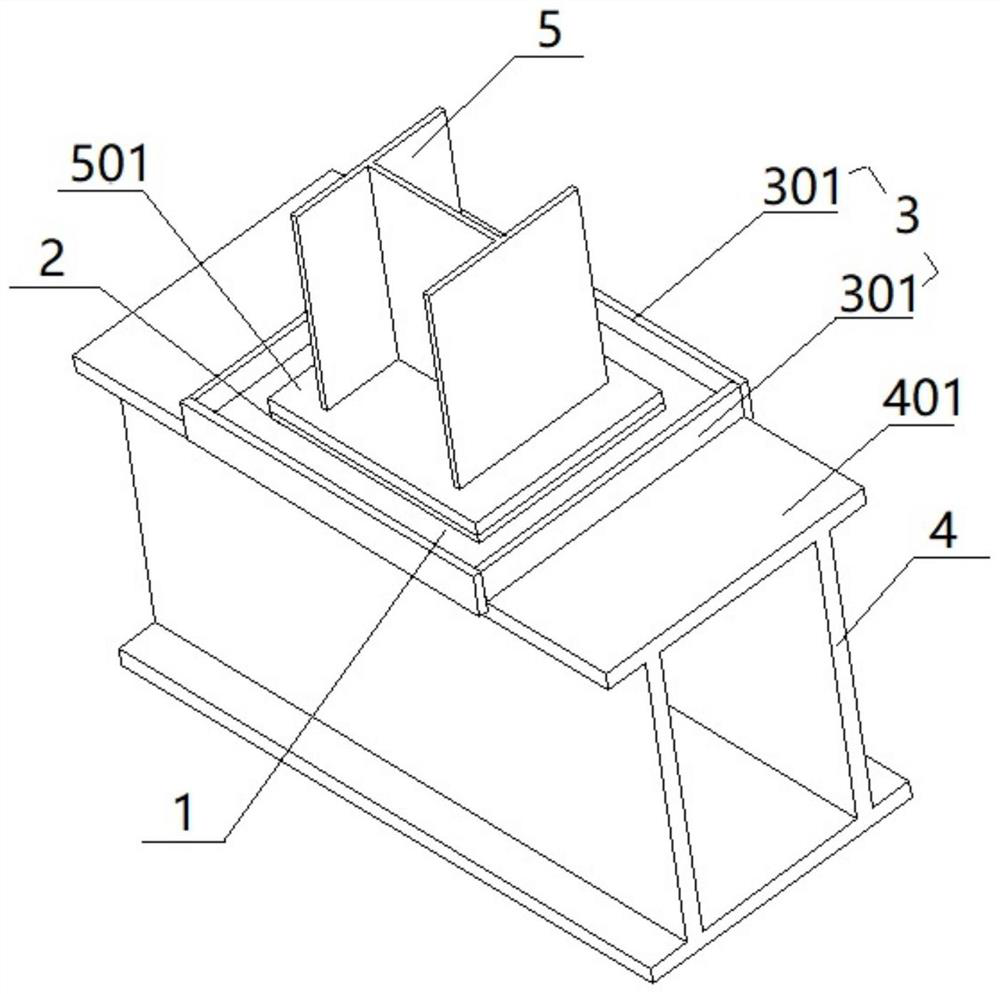

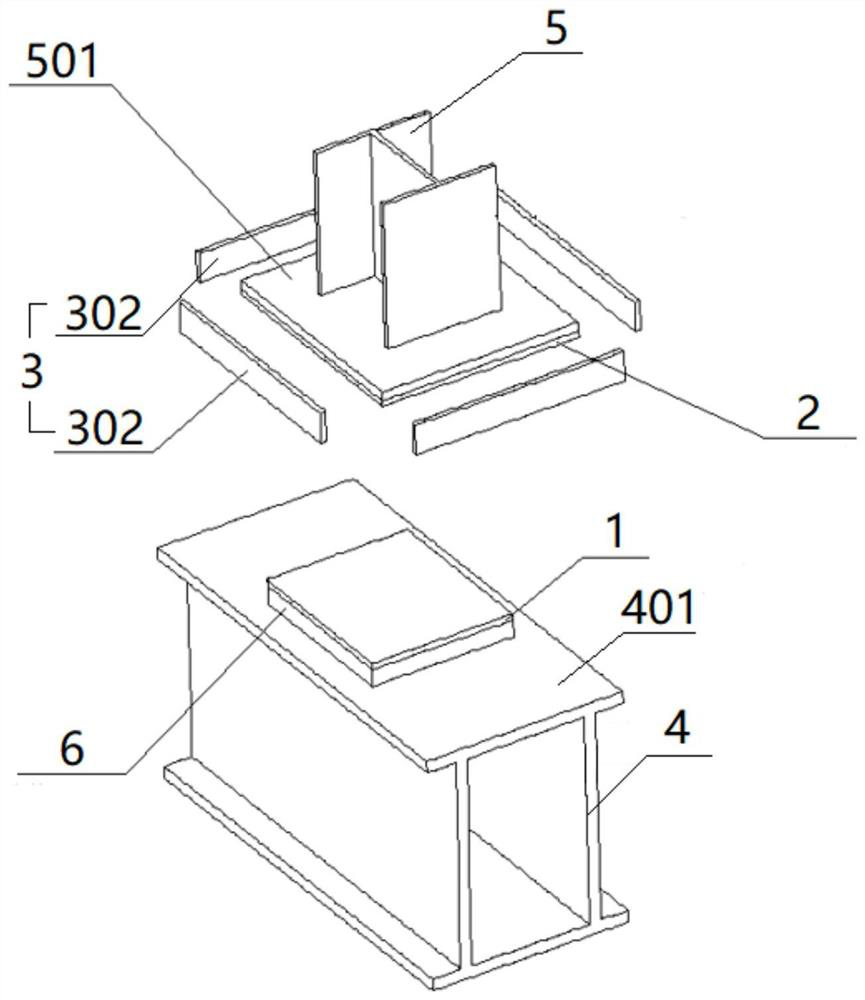

[0049] The embodiment of the present invention provides a sliding node of trestle legs, the schematic diagram of its structure splitting is as follows figure 1 or image 3 or Figure 5 or Figure 7 As shown, the node includes: a first plate body 1 , a second plate body 2 and a limiting member 3 .

[0050] Wherein, the first plate body 1 is arranged on the top plate 401 of the steel beam 4 of the transfer station, and the second plate body 2 is arranged on the bottom plate 501 of the trestle leg 5;

[0051] In the first possible implementation manner, the limiting member 3 is arranged on the top plate 401; in the second possible implementation manner, the limiting member 3 is arranged on the bottom plate 501; in the third possible implementation mann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com