Ultrasonic device

A technology of ultrasonic waves and steps, applied in radio wave measurement systems, instruments, etc., can solve problems such as complex structure and poor anti-environmental interference ability, and achieve the effect of improving accuracy and anti-environmental interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

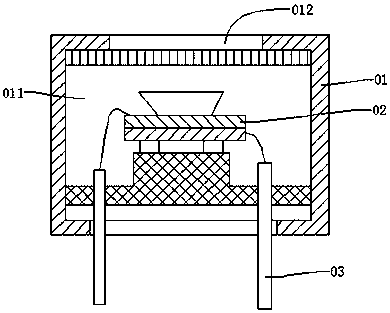

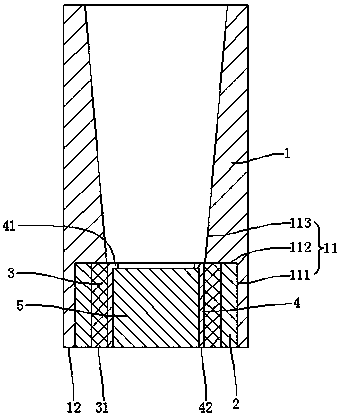

[0030] refer to figure 2 , an ultrasonic device, including a horn 1, a sealing ring 2, a flexible ring 3, a fixed ring 4 and a vibrating assembly 5, the vibrating assembly 5 includes several piezoelectric wafers, the vibrating assembly 5 is arranged in the sealing ring 2, and the fixed ring 4 is sleeved on On the vibrating assembly 5, the flexible ring 3 is clamped between the fixed ring 4 and the sealing ring 2, and the horn 1 is provided with a stepped hole 11, and the stepped hole 11 includes an upper stepped portion 111, a lower stepped portion 113 and a 111 and the connecting portion 112 of the lower stepped portion 113, the sealing ring 2 is inserted into the stepped hole 11, the sealing ring 2 is against the upper stepped portion 111 and the connecting portion 112, the connecting portion 112 and the vibrating assembly 5 are misplaced, along the stepped hole 11 In the axial direction, the lower step portion 113 includes at least two radial sections with different areas....

Embodiment 2

[0041] An ultrasonic device, including a horn, a sealing ring, a flexible ring, a fixed ring and a vibrating assembly, the vibrating assembly includes several piezoelectric wafers, the vibrating assembly is arranged in the sealing ring, the fixed ring is placed on the vibrating assembly, and the flexible ring is clamped on the fixed Between the ring and the sealing ring, there is a stepped hole on the horn. The stepped hole includes an upper stepped portion, a lower stepped portion and a connecting portion for connecting the upper stepped portion and the lower stepped portion. The sealing ring is inserted into the stepped hole. The sealing ring and The upper stepped part is in contact with the connecting part, and the connecting part and the vibrating assembly are dislocated. Along the axial direction of the stepped hole, the lower stepped part includes at least two radial sections with different areas.

[0042] In order to realize that the lower stepped portion includes at lea...

Embodiment 3

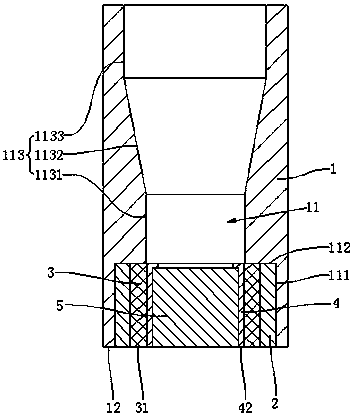

[0044] refer to image 3 , an ultrasonic device, including a horn 1, a sealing ring 2, a flexible ring 3, a fixed ring 4 and a vibrating assembly 5, the vibrating assembly 5 includes several piezoelectric wafers, the vibrating assembly 5 is arranged in the sealing ring 2, and the fixed ring 4 is sleeved on On the vibrating assembly 5, the flexible ring 3 is clamped between the fixed ring 4 and the sealing ring 2, and the horn 1 is provided with a stepped hole 11, and the stepped hole 11 includes an upper stepped portion 111, a lower stepped portion 113 and a 111 and the connecting portion 112 of the lower stepped portion 113, the sealing ring 2 is inserted into the stepped hole 11, the sealing ring 2 is against the upper stepped portion 111 and the connecting portion 112, the connecting portion 112 and the vibrating assembly 5 are misplaced, along the stepped hole 11 In the axial direction, the lower step portion 113 includes at least two radial sections with different areas. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com