Compact electromagnetic proportion valve

An electromagnetic proportional valve, compact technology, applied in the field of hydraulic valves, can solve the problems of large valve pressure drop, difficult disassembly and assembly, difficult to guarantee process size, etc., to avoid high load stop, avoid low load too fast, oil passage Effects of layout rules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

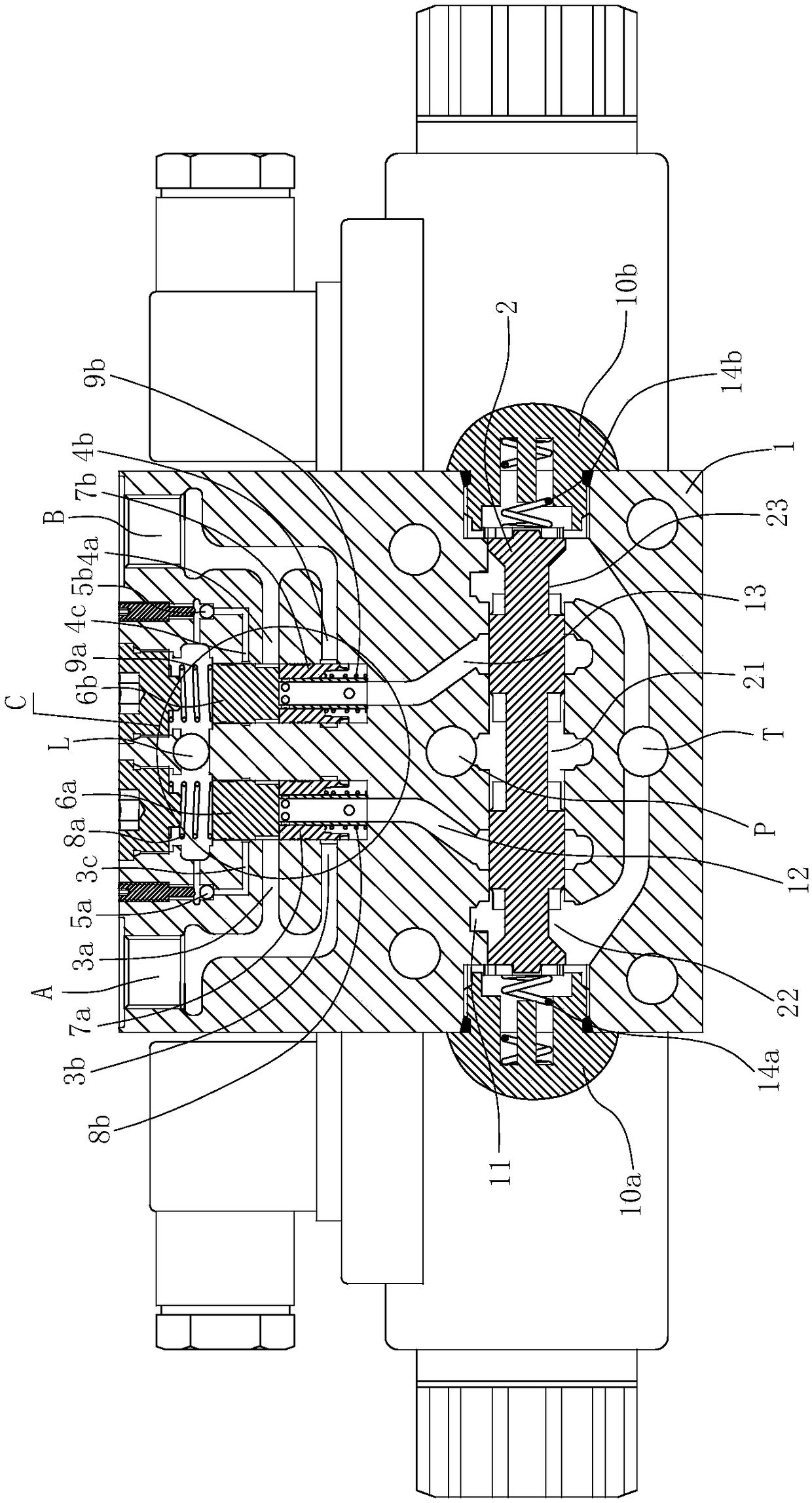

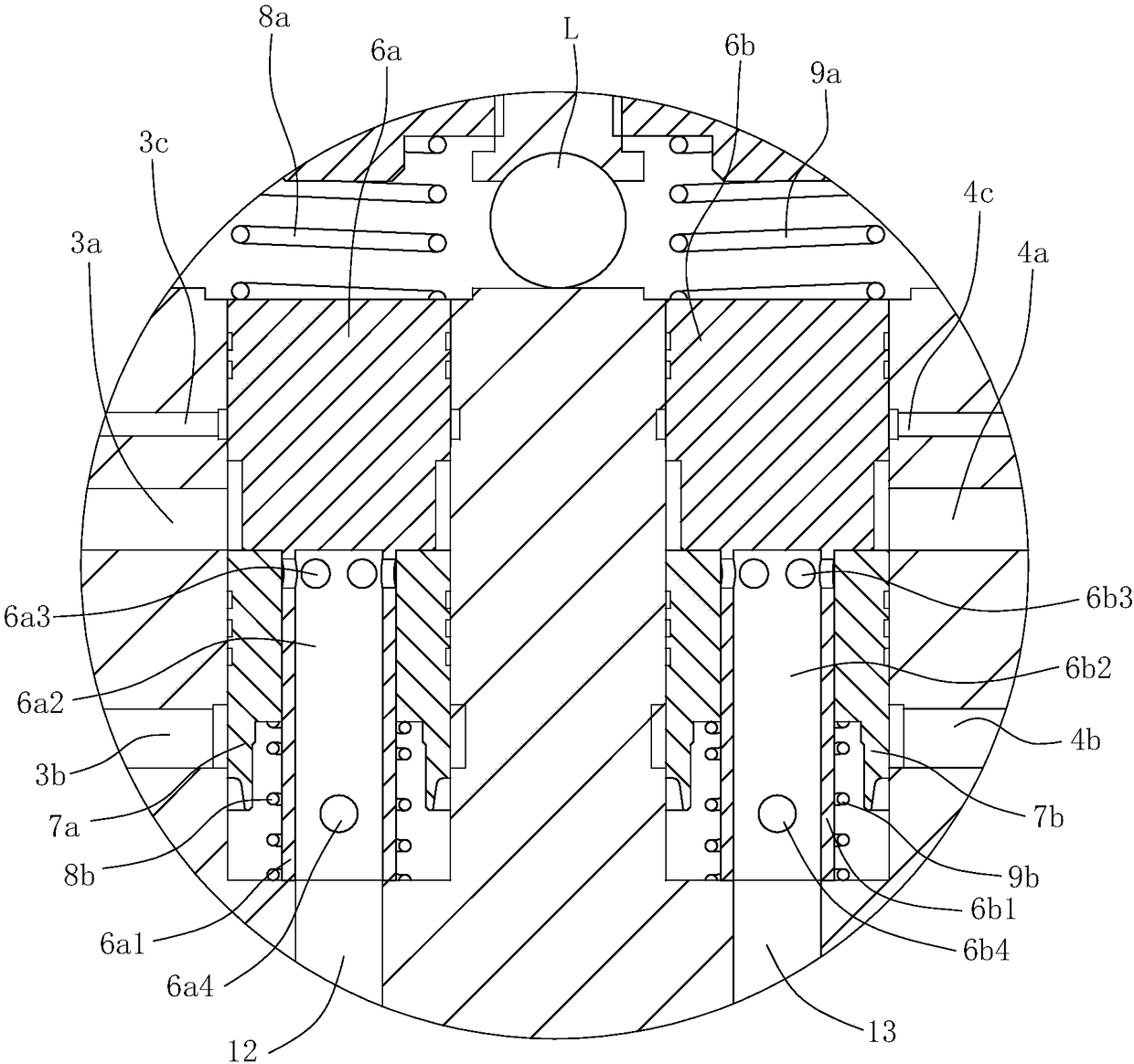

[0018] Such as figure 1 , 2 Shown is a preferred embodiment of the present invention.

[0019] A compact solenoid proportional valve comprising

[0020]A valve block 1 having a transverse shaft hole 11, a left vertical shaft hole 12 and a right vertical shaft hole 13, the left vertical shaft hole 12 and the right vertical shaft hole 13 are located above the transverse shaft hole 11 and respectively connected to the transverse shaft hole 11 Connected, the valve block 1 is provided with a pressure oil port P, a first working oil port A, a second working oil port B, an oil return port T and a load pressure feedback port L, wherein the pressure oil port P communicates with the transverse shaft hole 11 And located between the left vertical shaft hole 12 and the right vertical shaft hole 13, the oil return port T is respectively connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com