Temperature sensor connecting structure and connecting system

A temperature sensor and connection structure technology, applied in the field of sensors, can solve problems such as potential safety hazards, and achieve the effects of convenient rotation, high safety performance, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

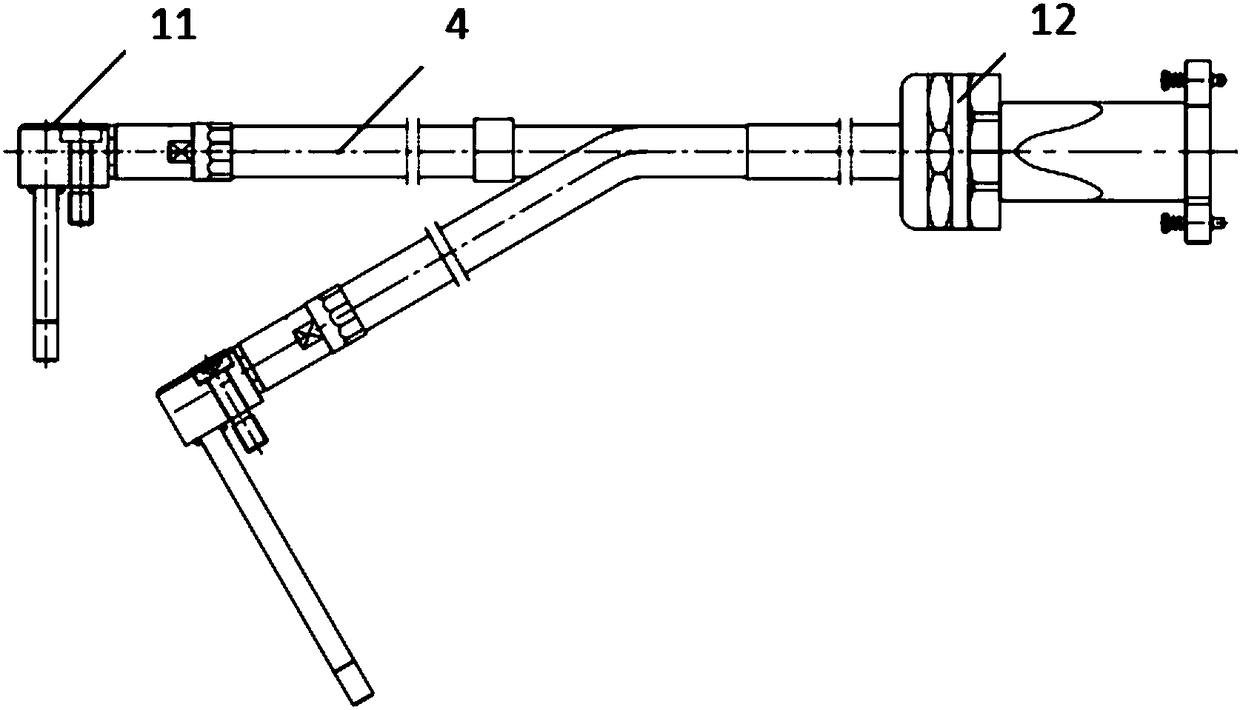

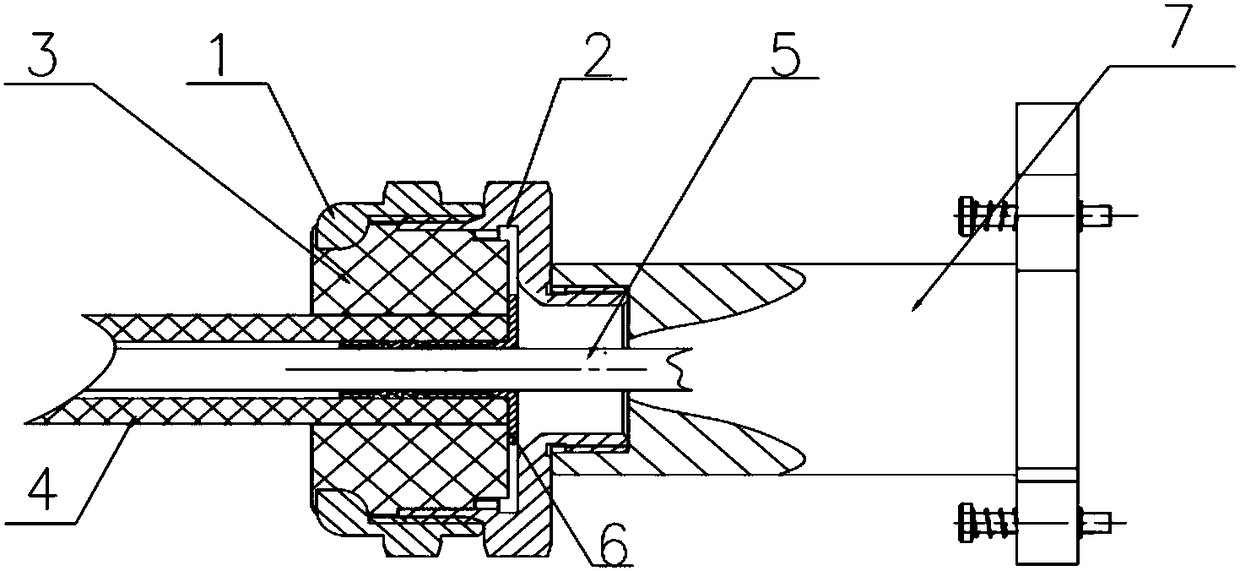

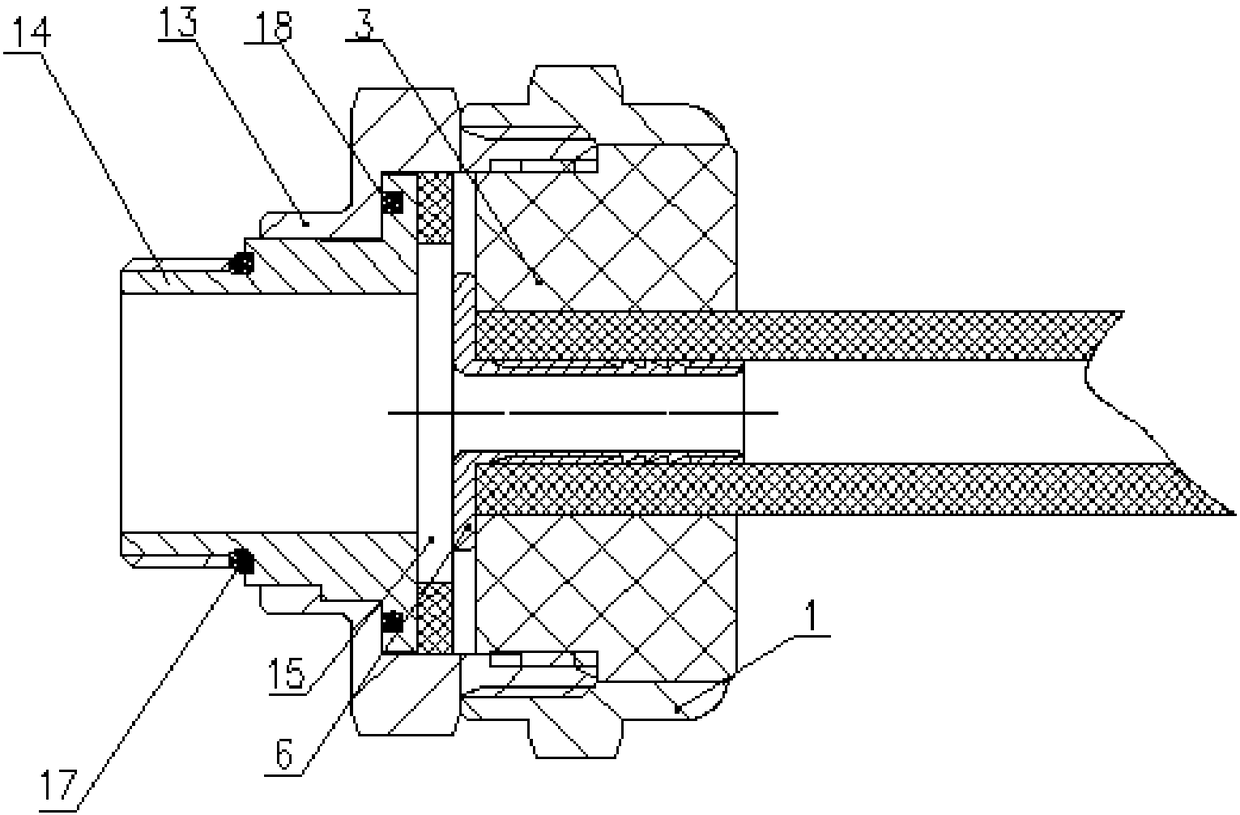

[0046] Such as Figure 3 to Figure 6 As shown, the temperature sensor connection mechanism provided by the first aspect of the present invention is arranged between the protective rubber hose 4 and the electrical connector 7, including the connected sealing nut 1 and the second sealing bolt 13, and the protective rubber hose 4 is arranged on the In the sealing nut 1, a sealing rubber plug 3 is arranged between the protective rubber hose 4 and the sealing nut 1; the second sealing bolt 13 is connected to the electrical connector 7 through a limiting core 14, so that A limiting member is provided between the second sealing bolt 13 and the limiting core 14 .

[0047]In the connection structure of the temperature sensor provided by the present invention, the second sealing bolt 13 is connected to the electrical connector 7 through a limiting core 14, and a limited space is set between the second sealing bolt 13 and the limiting core 14. bit pieces. The position-limiting core 14 ...

Embodiment 2

[0058] Such as Figure 7 As shown, in any of the above technical solutions, further, the limiting member is a connecting member 19, and the second sealing bolt 13 and the limiting core 14 are correspondingly provided with through holes, and the connecting member 19 is passed through the inside the through hole.

[0059] In any of the above technical solutions, further, the connecting member 19 is a pin or a screw. The electrical connector 7 is provided with a fixing piece.

[0060] Change the limiting method of the sealing bolt and the limiting core 14 from the internal milling groove of the structural part to a through hole, and insert a pin or a hexagon socket set screw. The disadvantage of this method is that the pores produced after drilling will lead to a decrease in sealing, and a sealant can be provided between the connecting piece 19 and the through hole, so that the sealing effect is better.

[0061] Over time, the aging of the sealant can lead to a deterioration o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com