Non-inflammable lithium secondary battery and application thereof

A lithium secondary battery, lithium salt technology, applied in the field of electrochemical and chemical power products, can solve the problems of no reversible capacity, graphite layered structure damage, low coulombic efficiency of graphite negative electrode, etc., to improve coulombic efficiency and reversible capacity, High security effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] In a glove box filled with argon gas, lithium salt and organic phosphorus solvent are mixed to prepare nonflammable electrolyte: the organic phosphorus solvent selected in this embodiment is TMP, TEP, DMMP, DEEP, and the lithium salt selected is LiTFSI and LiFSI; wherein, The molar ratio of lithium salt and organophosphorus solvent is 1:2, and 0-10wt% FEC, VC or LiBOB are added as film-forming additives, assembled into a CR2016 battery and tested for electrochemical performance.

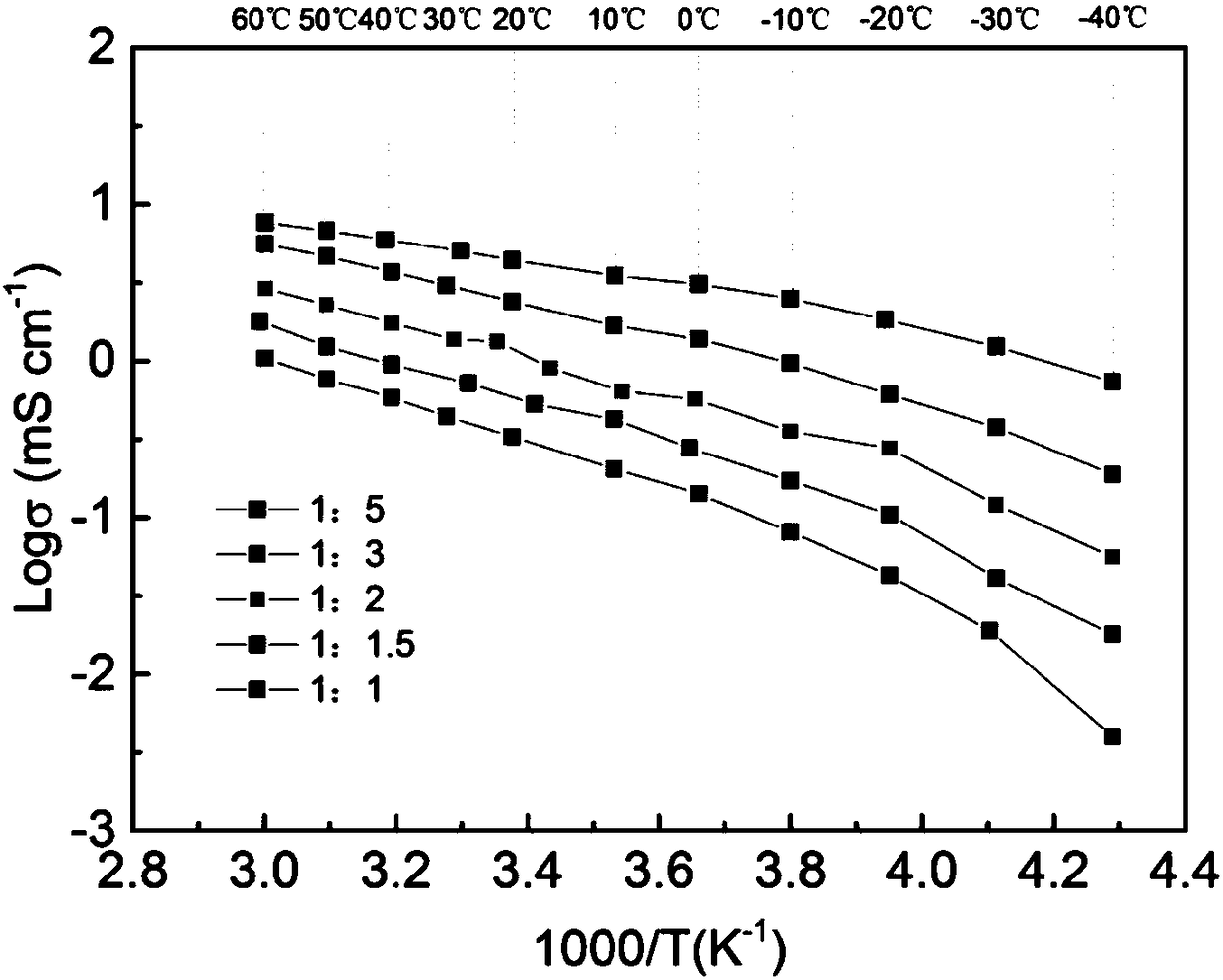

[0033] The electrical conductivity of the non-flammable electrolyte system composed of different mole fractions of lithium salt LiFSI and organophosphorus solvent TEP in the range of -40 to 60 ° C is explored as a function of temperature. The relationship between conductivity and temperature is as follows figure 1 shown.

Embodiment 2

[0035] The negative electrode material used in this embodiment is artificial graphite, and the positive electrode material is LiCoO 2 , the production method of the electrode pole piece is as follows:

[0036] Negative electrode sheet: artificial graphite, 1.5wt% carboxymethylcellulose sodium (CMC), 1.5wt% styrene-butadiene rubber (SBR) aqueous solution and acetylene black or Super P are mixed in a mass ratio of 85:3:3:9, Stir and mix thoroughly with a micro ball mill, pour it on the copper foil to coat the film, vacuum dry and punch out the corresponding size (about 0.5cm 2 ) of the negative electrode film, compacted under 20Mpa, weighed and set aside.

[0037] Positive electrode sheet: the positive electrode material LiCoO 2 , Methylpyrrolidone (NMP) solution containing 4wt% polyvinylidene fluoride (PVDF) and acetylene black are mixed at a mass ratio of 80:10:10, stirred and mixed thoroughly with a micro-ball mill, then poured on the aluminum foil for coating, dried in vac...

Embodiment 3

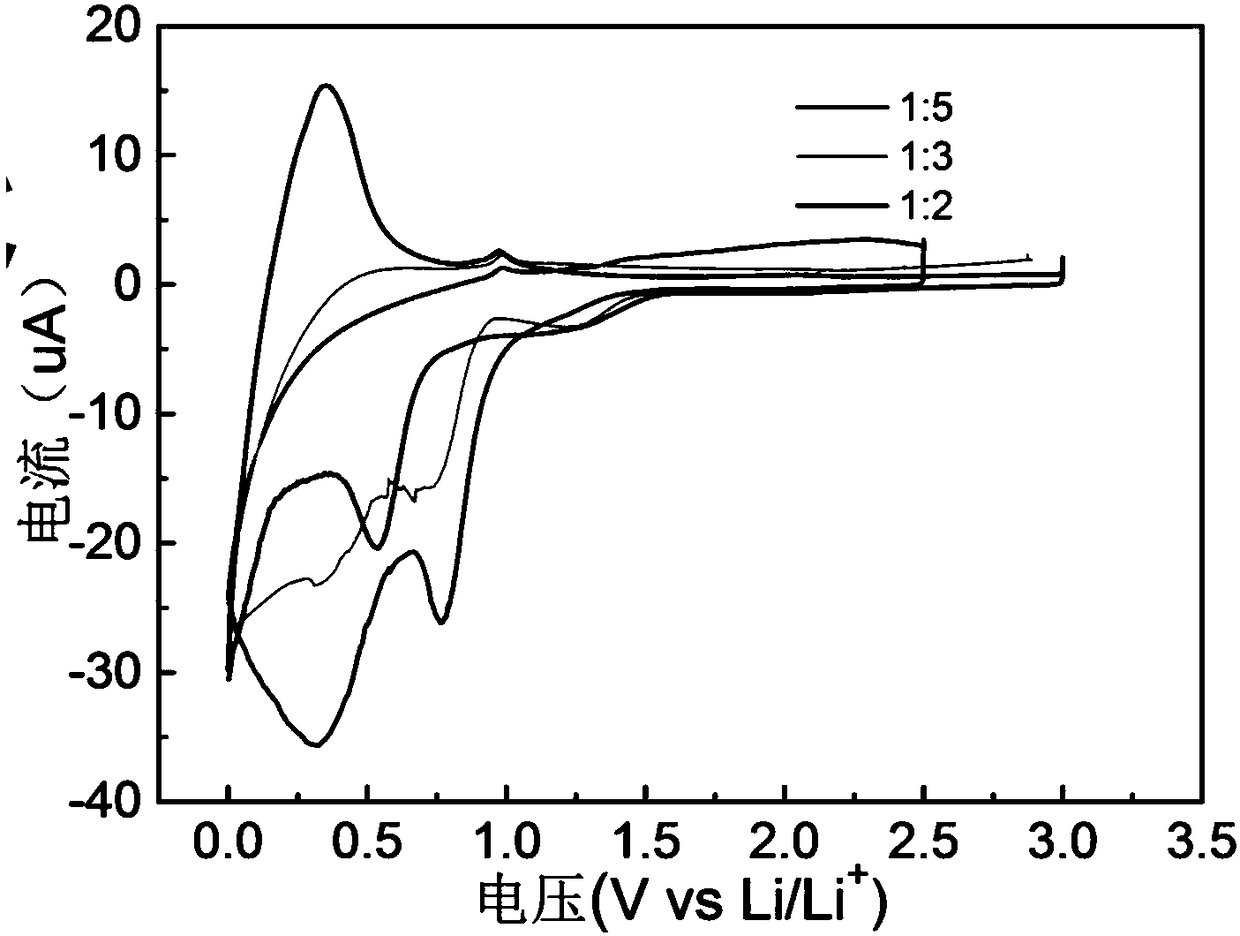

[0040]Comparative test of high mole fraction lithium salt non-flammable electrolyte and low mole fraction lithium salt non-flammable electrolyte used in graphite negative electrode system:

[0041] Preparation of non-flammable electrolyte: The lithium salt used in this example is LiTFSI, the organic phosphorus solvent is TMP, and the molar ratios of lithium salt and organic phosphorus solvent in the prepared non-flammable electrolyte are 1:5, 1:3, 1:2, 1:1.5, 1:1, the corresponding mole fractions of lithium salts are 16.7%, 25%, 33.3%, 40%, and 50%. Using artificial graphite as the positive electrode and metal lithium as the negative electrode, assemble CR2016 battery, the diaphragm is a single-sided coated ceramic diaphragm, and the ceramic layer is opposite to the artificial graphite pole. On the LAND battery tester, after standing for 6 hours, first use 20mA·g -1 The current density is cycled for 3 weeks, and then at 50mA·g -1 The current density of the charge and dischar...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap