Method for preparing sulfur trioxide by utilizing gypsum and equipment system thereof

A technology for sulfur trioxide and gypsum, which is applied in the field of sulfur trioxide preparation to achieve the effects of reducing production costs, reducing the greenhouse effect, and being beneficial to industrialized production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

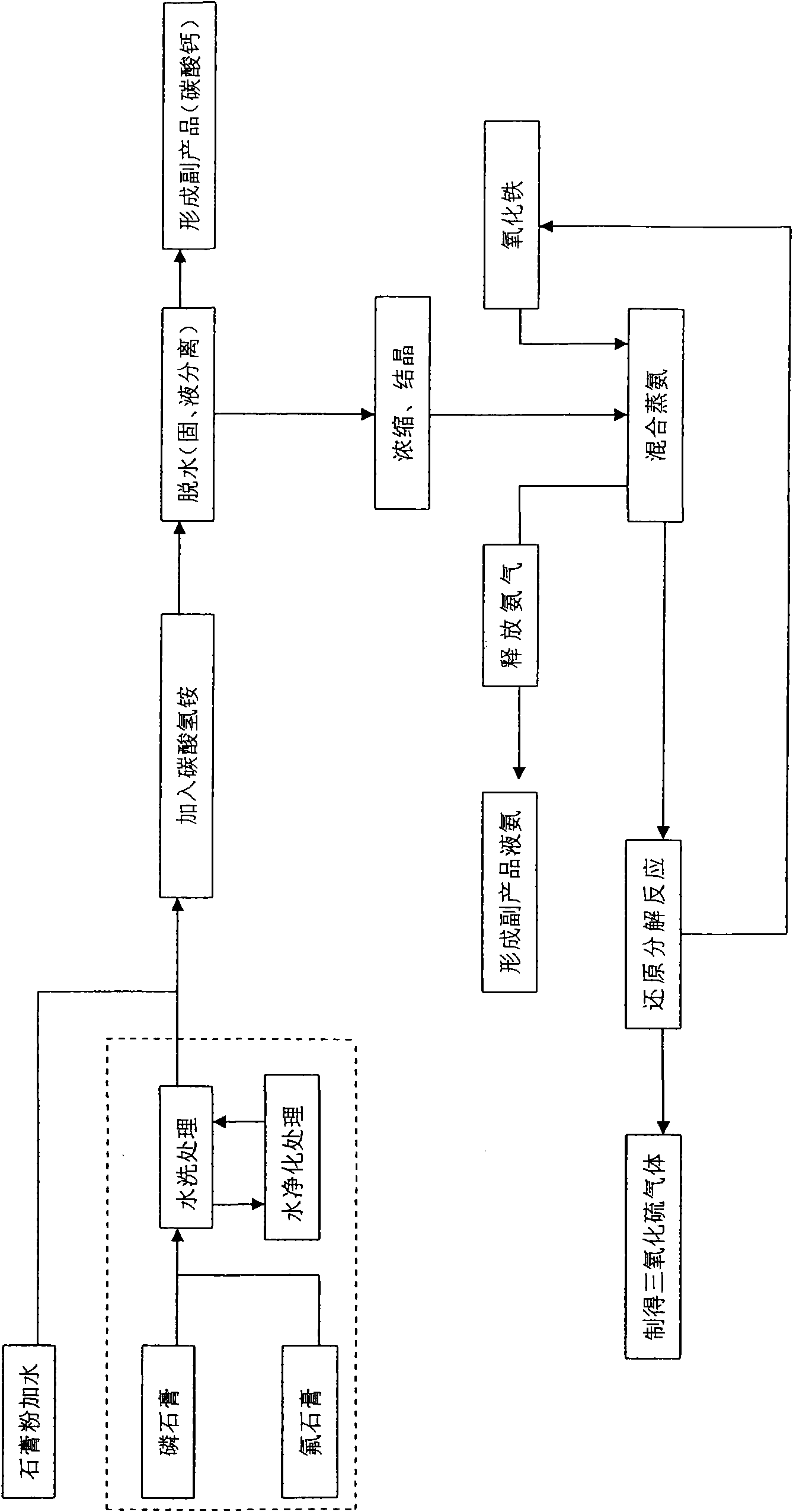

[0053] Embodiment 1——phosphogypsum produces sulfur trioxide (with ammonium bicarbonate method)

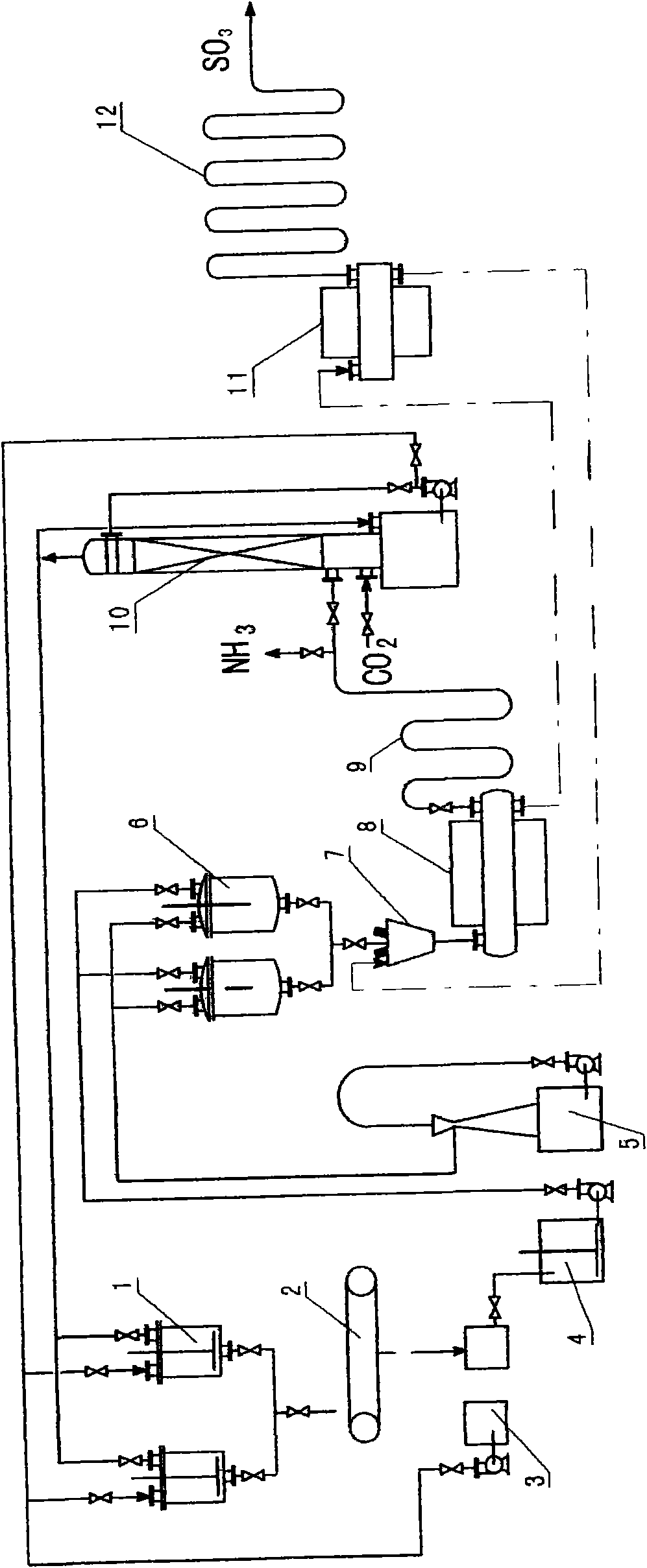

[0054] See figure 1 , image 3 . The phosphogypsum is washed twice in the cement pool, mainly to remove the soluble P in the phosphogypsum 2 o 5 , F - After the phosphogypsum precipitates and the organic matter suspended on the water surface, the upper liquid is sucked off to obtain a gypsum slurry mixed with the precipitated phosphogypsum and water (control the water content at ≤ 50%).

[0055] (1) Metathesis reaction: In the reaction kettle 1 with a paddle agitator, 1 part of phosphogypsum (the main component is CaSO 4 2H 2 O content is 82%, without water), adding ammonium bicarbonate (NH 4 HCO 3 content is 98%) 1.2 parts, reacted for 1 hour at a temperature of 30°C to 50°C to obtain calcium carbonate and ammonium sulfate [(NH 4 ) 2 SO 4 ] in aqueous solution.

[0056] (2) Dehydration treatment: filter with belt filter 2, carry out solid and liquid two-phase separatio...

Embodiment 2

[0060] Embodiment 2——Gypsum powder produces sulfur trioxide (with ammonium bicarbonate method)

[0061] (1) Metathesis reaction: 1 part of natural gypsum mineral powder (CaSO 4 2H 2 O content is 88%), particle diameter is below 50um), add ammonium bicarbonate (NH 4 HCO 3 Content is 98%) 1.2 parts. In the reaction kettle 1 with a paddle stirrer, react at a temperature of 30°C to 50°C for 1 hour to obtain calcium carbonate and ammonium sulfate [(NH 4 ) 2 SO 4 ] in aqueous solution.

[0062] (2) Dehydration treatment: filter with belt filter 2, carry out solid and liquid two-phase separation, separate calcium carbonate by-product, and ammonium sulfate aqueous solution enters liquid storage tank II 4.

[0063] (3) Concentration treatment: After the ammonium sulfate aqueous solution was concentrated by the evaporation concentrator 6 equipped with the jet pump 5, 0.68 parts of crystals of ammonium sulfate were obtained.

Embodiment 3

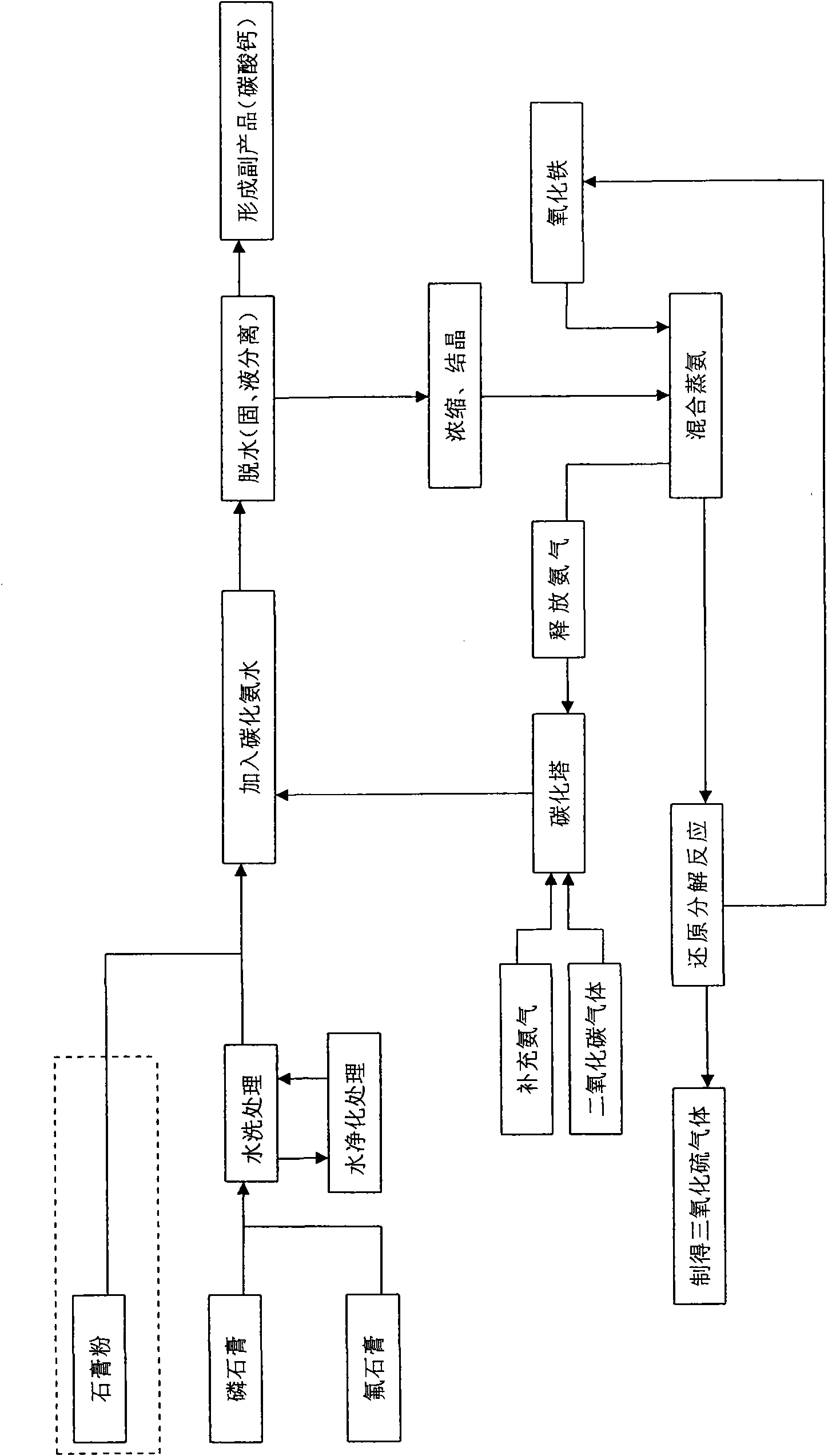

[0066] Embodiment 3——Gypsum powder produces sulfur trioxide (adding carbonized ammonia water method)

[0067] See figure 2 , image 3 . Add 2 parts of ammonia, 1 part of carbon dioxide and water to form a saturated solution (unsaturated solution will slow down the reaction speed) by carbonizing tower 10; put 1 part of natural gypsum mineral powder (CaSO 4 2H 2 O content is 90%), and the particle diameter is below 50um) for material preparation.

[0068] (1) Metathesis reaction: 1 part of natural gypsum mineral powder and 3.7 parts of carbonized ammonia water are reacted for 2 hours at a temperature of 30°C to 50°C in a reaction kettle 1 with a paddle stirrer to obtain calcium carbonate (by-product separation ) and ammonium sulfate [(NH 4 ) 2 SO 4 ] Aqueous solution.

[0069] (2) Dehydration treatment: filter with belt filter 2, carry out solid and liquid two-phase separation, separate calcium carbonate by-product, and ammonium sulfate aqueous solution enters liquid st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com