Adjusting device and nozzle frame

A technology of adjusting device and nozzle frame, which is applied in the field of nozzle frame, can solve problems such as cost increase, inconsistent adjustment reference, spring screw position is not fixed, etc., and achieves the effect of convenient adjustment, simple structure, and improved inkjet accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

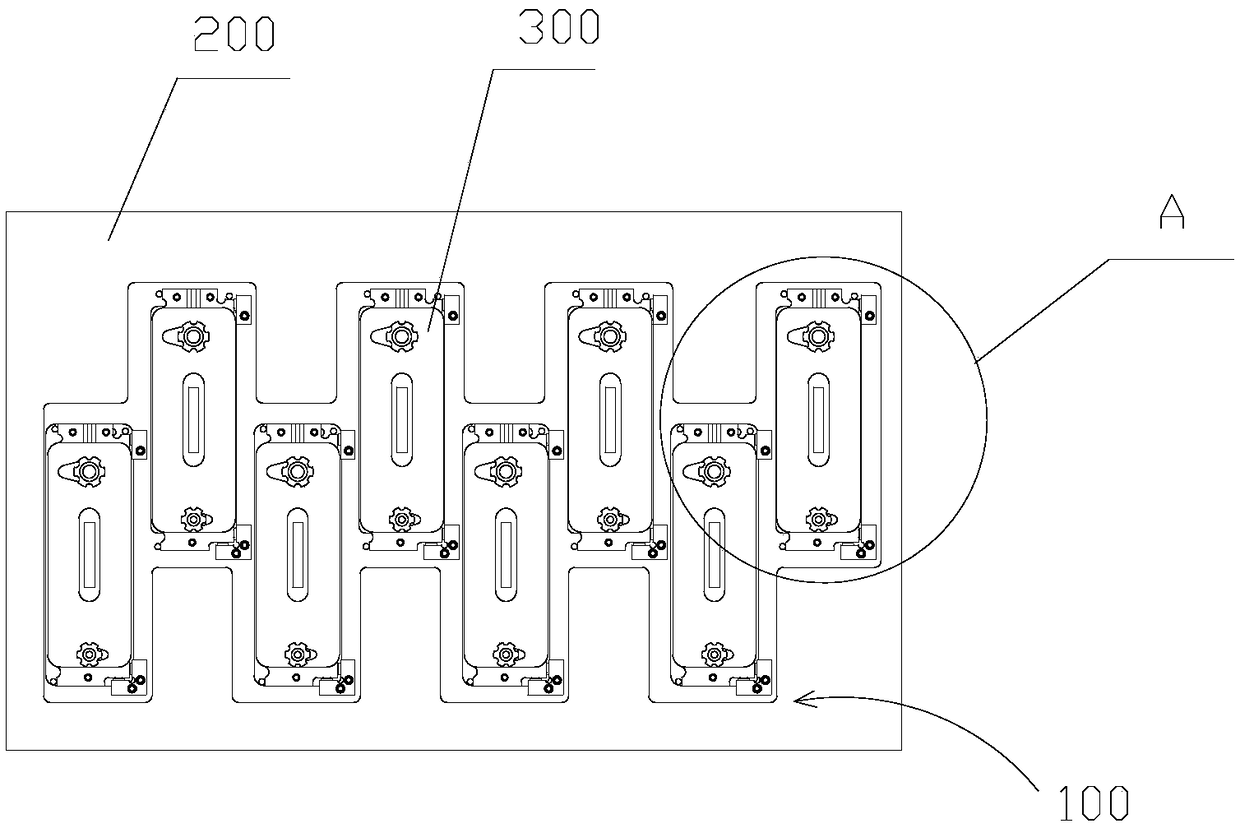

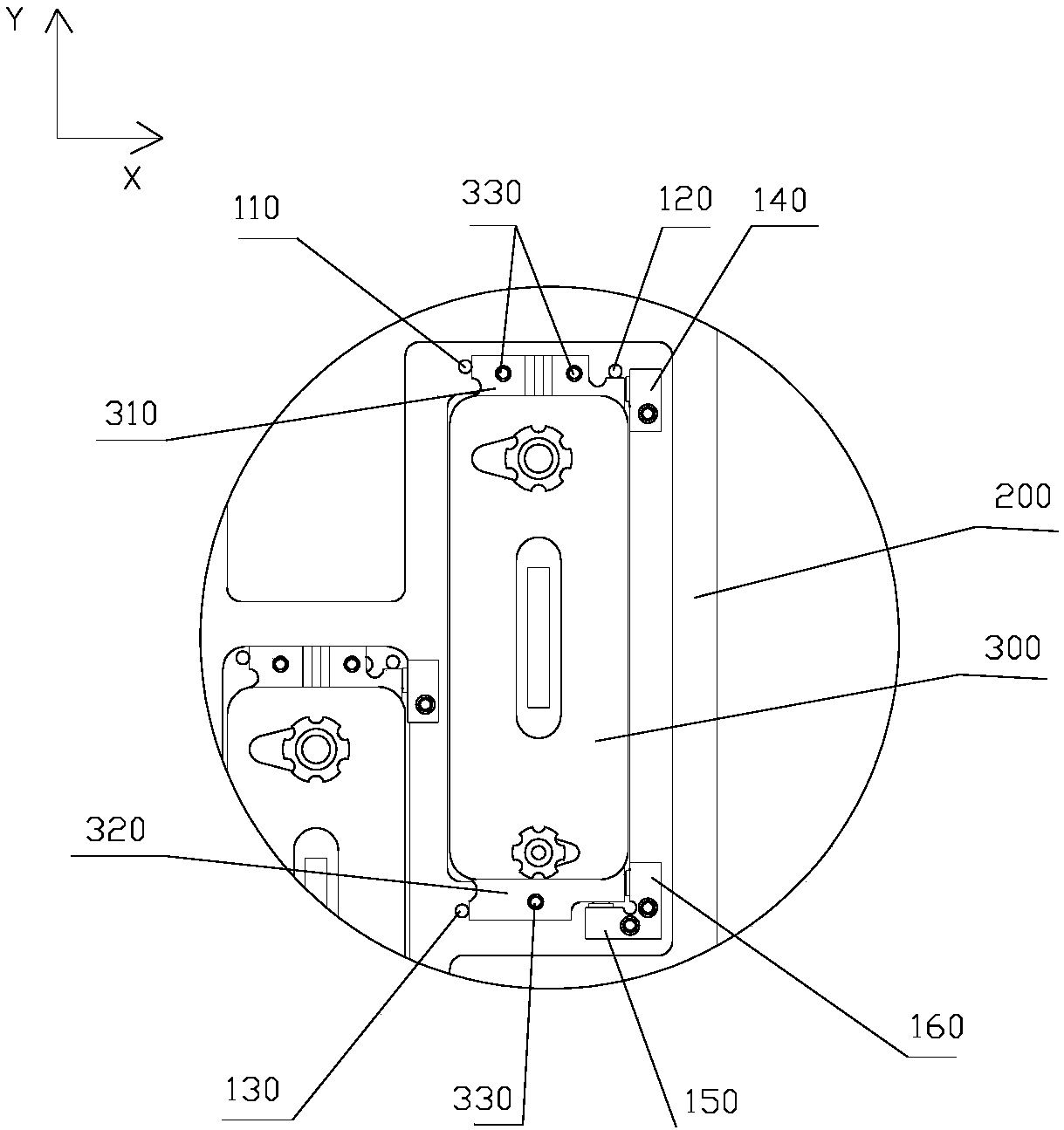

[0036] Such as Figures 1 to 3 As shown, the adjusting device 100 is installed on the mounting plate 200 and is used for adjusting the position of the workpieces 300 arranged on the mounting plate 200 . The adjustment refers to fine adjustment to keep the positions of multiple workpieces 300 consistent. The consistency of the positions means that the landing points of the nozzles in the same row on the medium are located on the same straight line, so that the accuracy of inkjet can be improved.

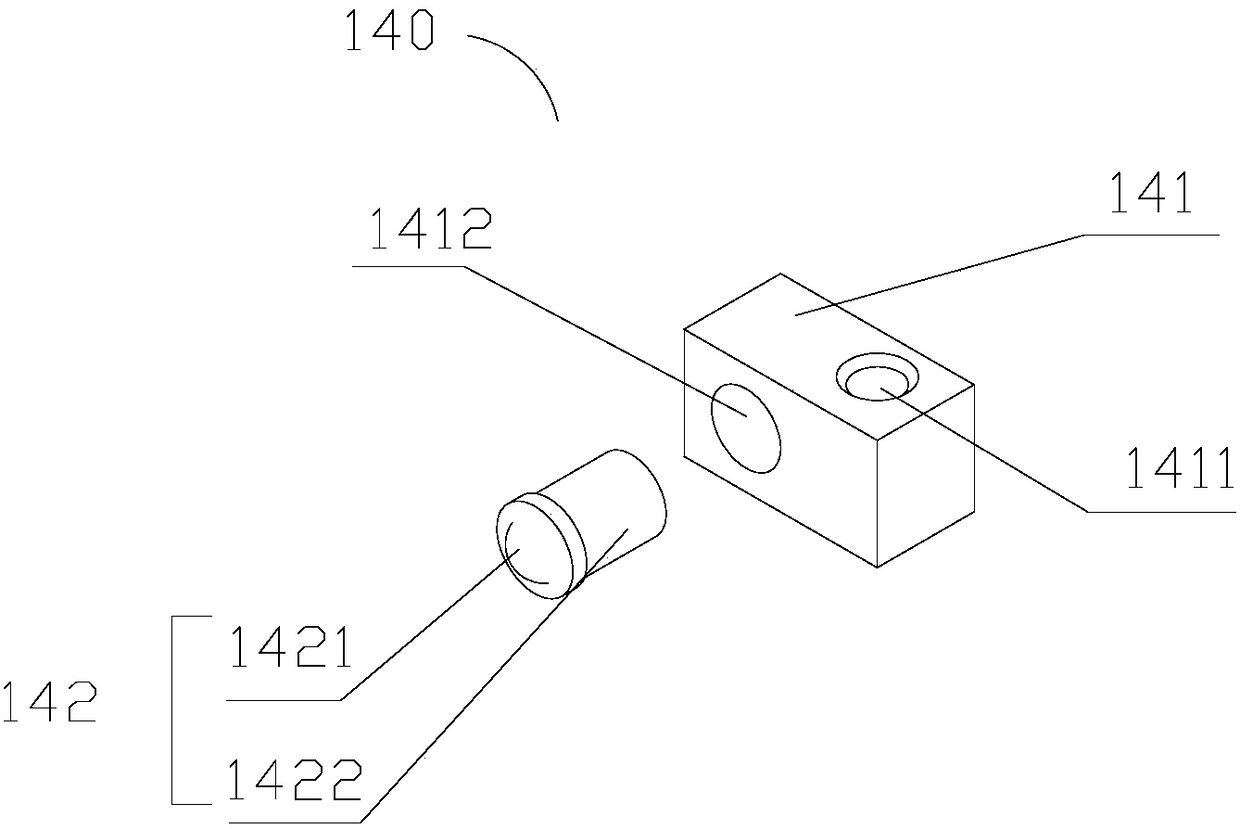

[0037] Such as figure 2 As shown, the adjusting device 100 includes a first limiting mechanism 110, a second limiting mechanism 120, a first adjusting mechanism 140 and a second adjusting mechanism 150, and the first limiting mechanism 110 and the first adjusting mechanism 140 are respectively positioned on the workpiece 300, and adjust the position of the workpiece 300 in the X-axis direction. The adjustment process refers to the first adjustment mechanism 140 pushing the workpiece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com