Passenger boarding and alighting system for evacuated tube high-speed train

A technology of high-speed trains and vacuum pipes, applied in tunnel systems, roads, stations, etc., can solve the problems of long docking time, not easy to achieve, and inconvenient for passengers to get on and off the train quickly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

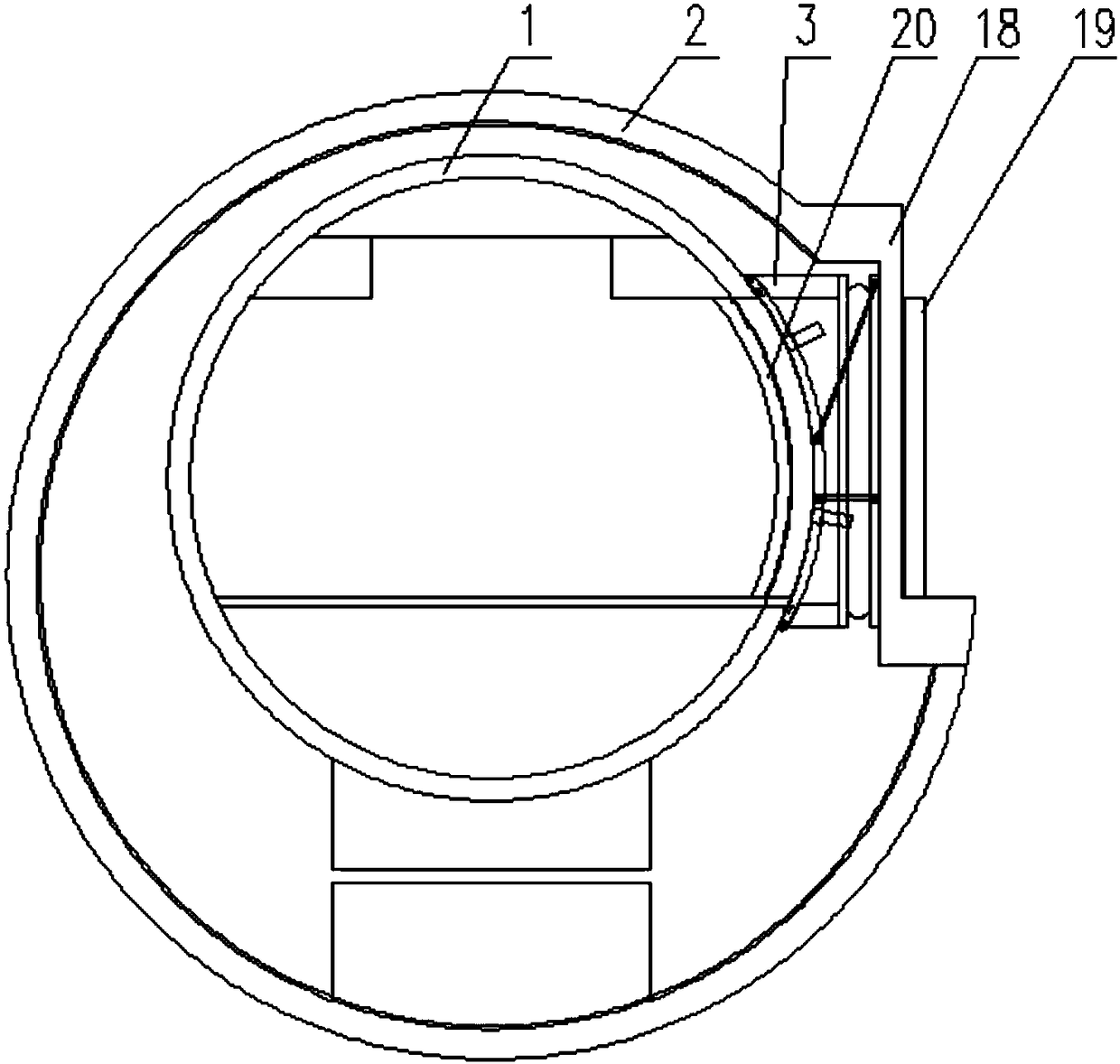

[0056] After the high-speed train 1 parks at the precise alignment on the platform, the airtight sliding door 20 of the train basically corresponds to the position of the boarding and disembarking compartment 3 (and the airtight wall 18 of the platform, the airtight sliding door 19 of the platform), forming a passageway for passengers, such as figure 1 shown.

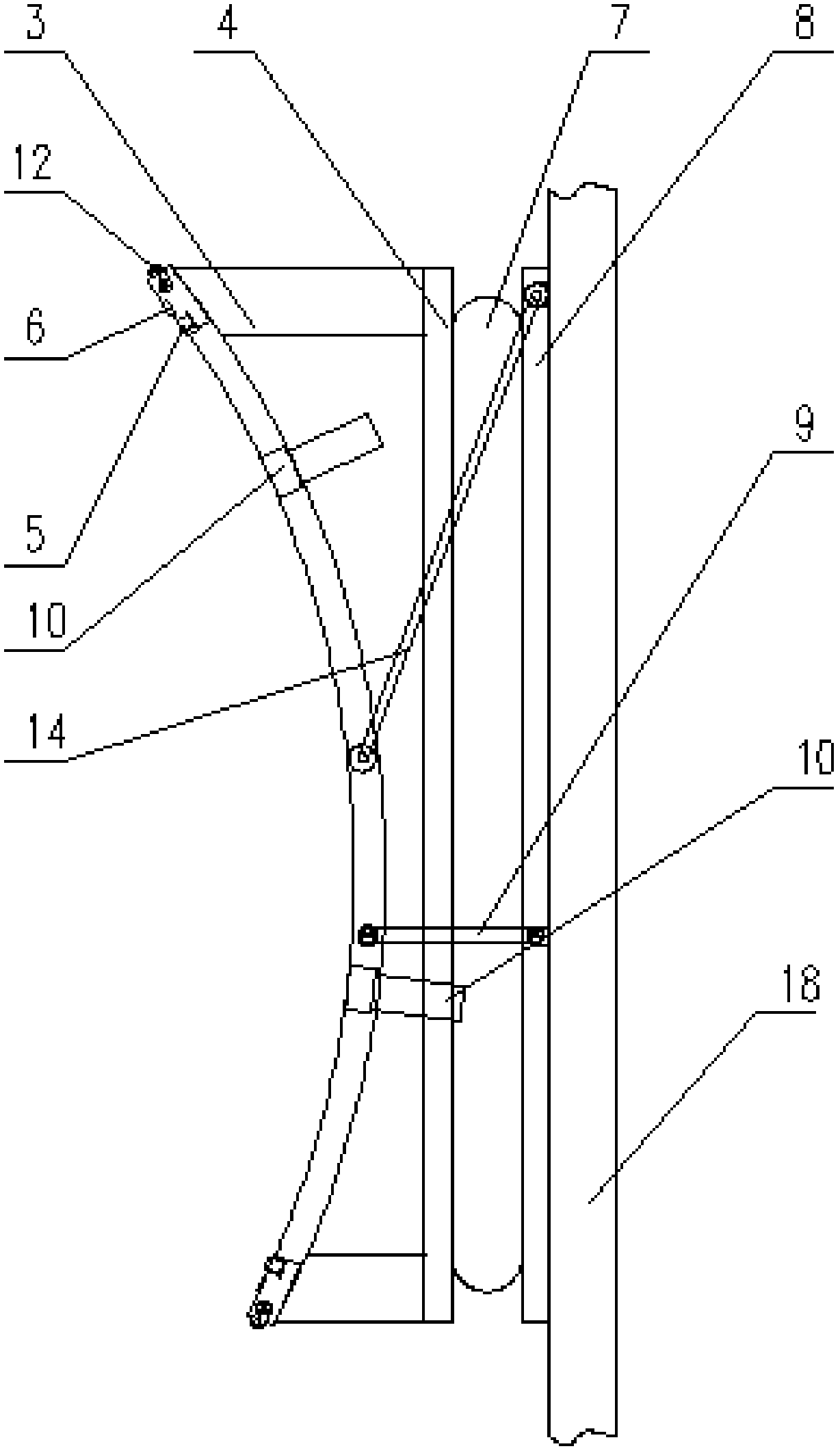

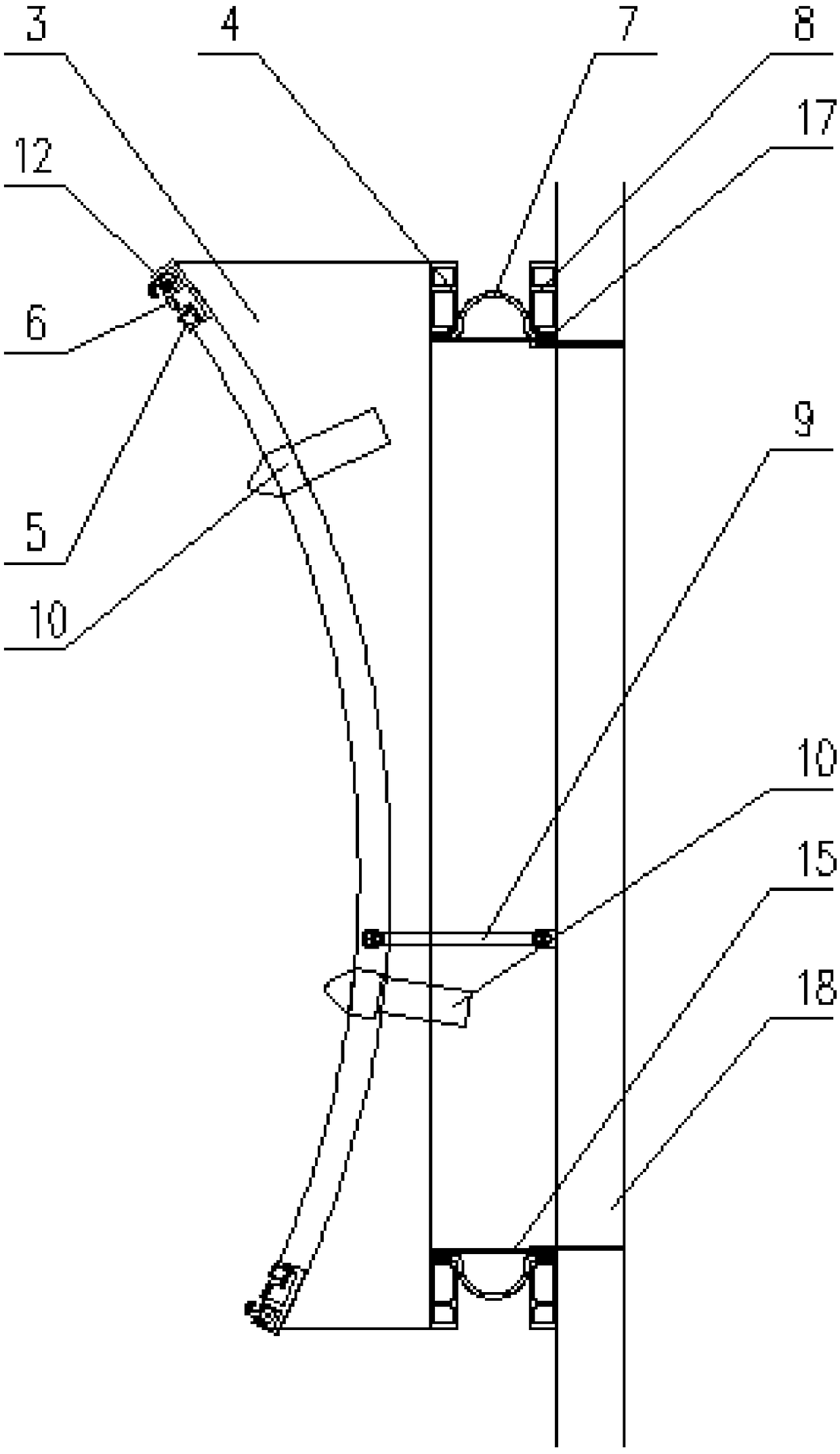

[0057] The movable frame 4 is equipped with a target identification camera 11, and the target identification camera 11 searches for the car body target identification 24 provided on the high-speed train 1, controls the guide rod 9, and pushes the movable frame 4 left and right, Move the alignment back and forth (one alignment), such as figure 2 shown. After the first alignment is completed, the guide cone I10-1 and guide cone II10-2 in the guide cone 10 move to move the lower part of the movable frame 4 to the position of the car body guide seat 25 of the high-speed train 1, and the The permanent magnetic ring 25-1 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com