Method and device for detecting born pulling force of pressed cable head

A technology of tension detection and cable head, which is applied in the direction of measuring force components, etc., to achieve the effect of simplifying the volume and the requirements for force sensors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

[0027] A method for detecting the tensile force of a pressed cable head. Firstly, a photoelectric detector is used to detect whether there is a relative displacement between the cable and the wire nose during the pulling process of the pressed cable head, and to judge whether there is a hollow phenomenon in the cable head; The pulling force is decomposed, and the cable head is judged whether it is qualified by detecting the component force value of the cable being pulled.

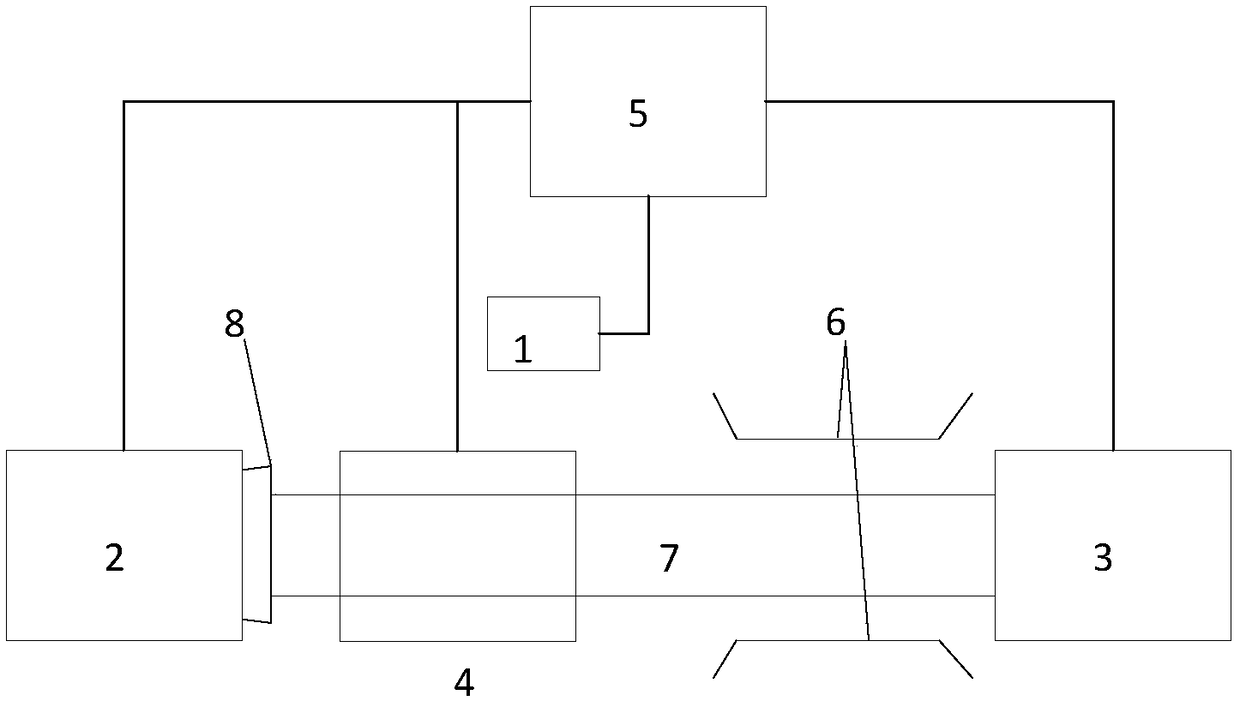

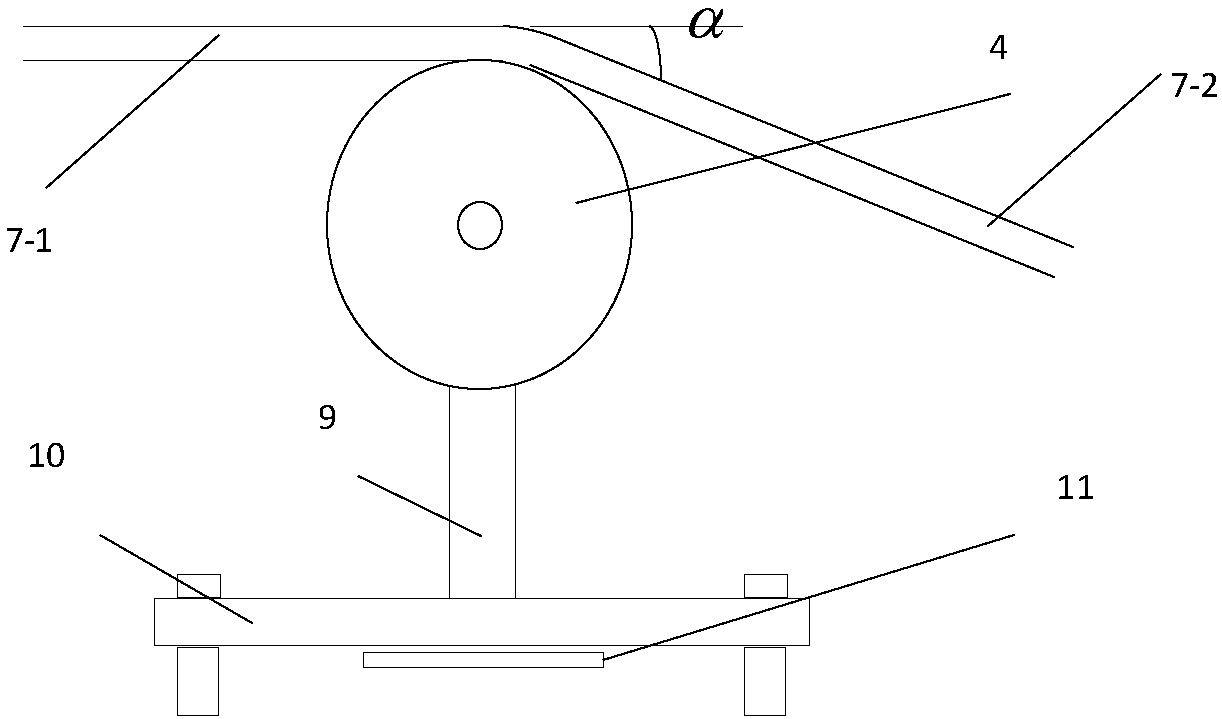

[0028] Such as figure 1 , 2 As shown, a pressed cable head carrying tension detection device includes a pressed cable head composed of a wire lug 8 and a cable 7, the wire lug 8 is installed at one end of the cable 7, and the wire lug 8 is fixed and compressed by pressing the tiger mouth 2, The end of the cable 7 is connected to the heig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com