Method for correcting gas loss volume of coal rock or shale

A calibration method and gas volume technology, applied in shale experiments and coal and rock fields, can solve problems such as accurate measurement of natural gas loss, algorithm or correction method correction without loss of gas volume, and error, so as to achieve accurate loss of gas volume and solve inaccurate measurement and calculation. or incalculable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

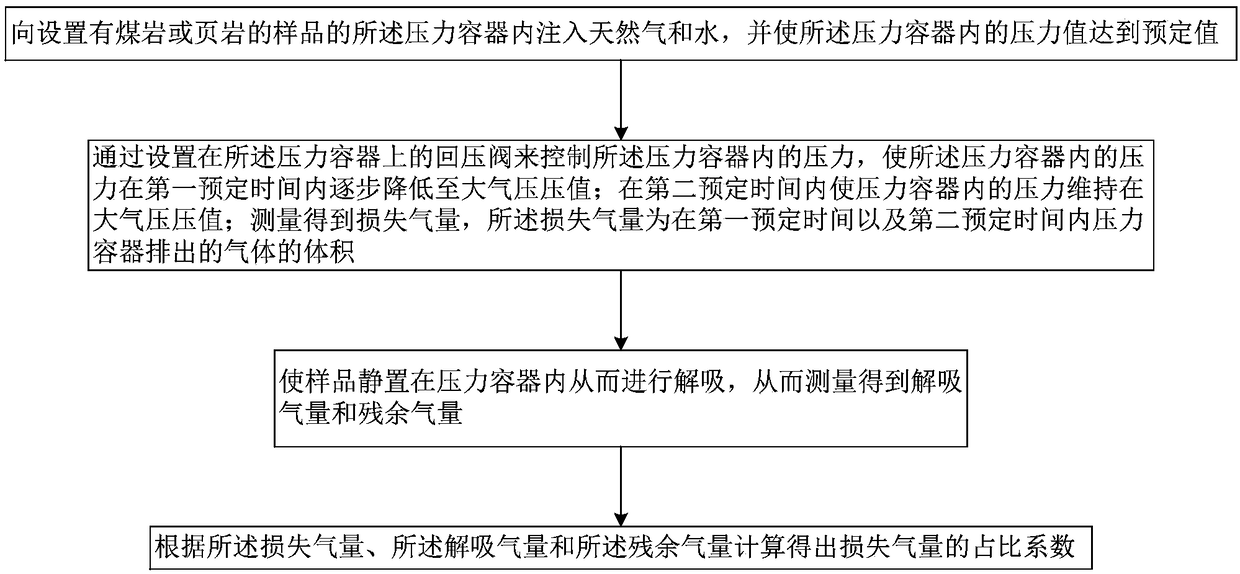

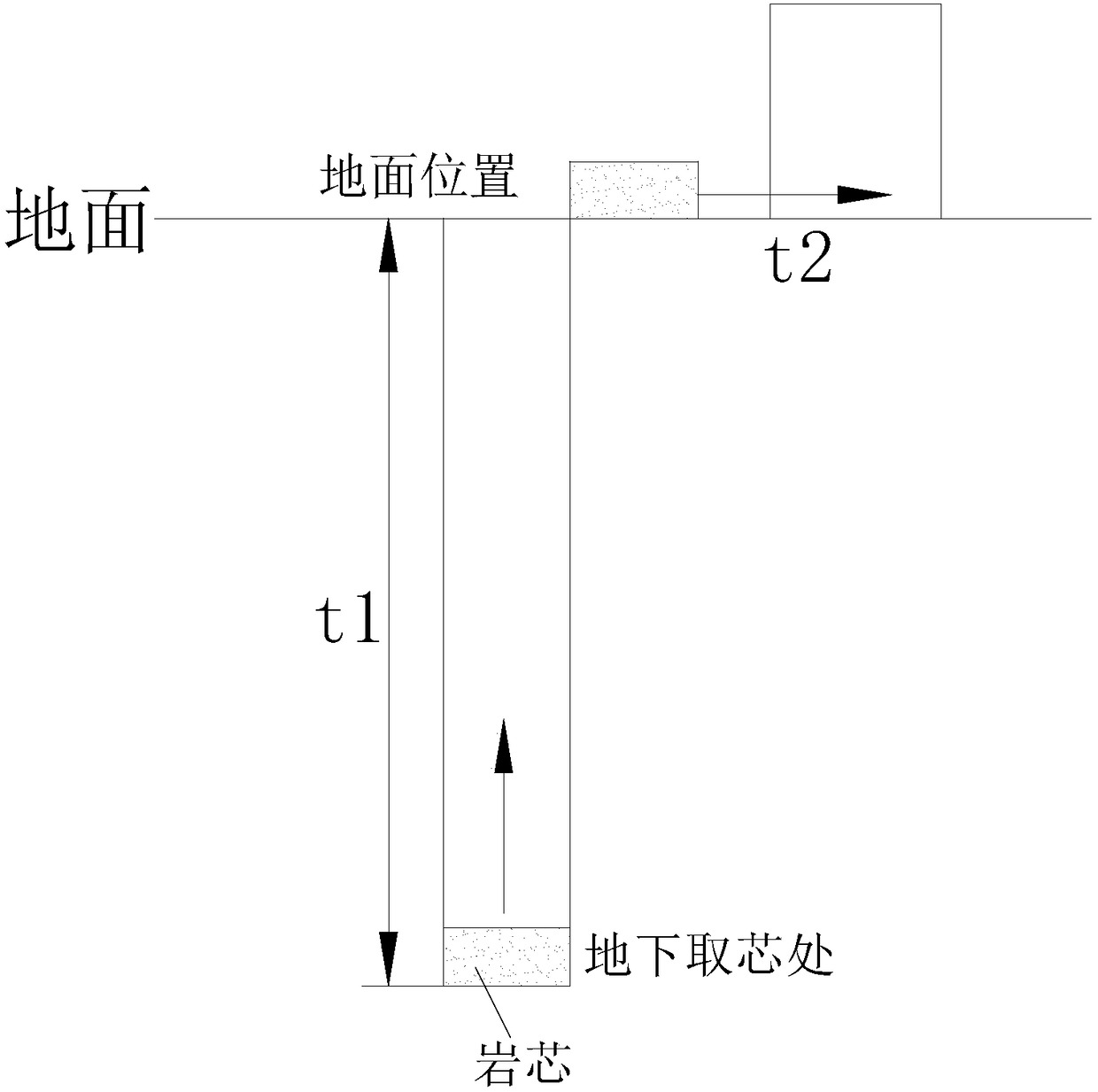

[0028] see figure 1 and figure 2 As shown, according to an embodiment of the present invention, a method for correcting gas loss in coal or shale is provided, comprising the following steps:

[0029] Step S10: Injecting natural gas and water into the pressure vessel provided with the coal rock or shale sample, and making the pressure in the pressure vessel reach a predetermined value;

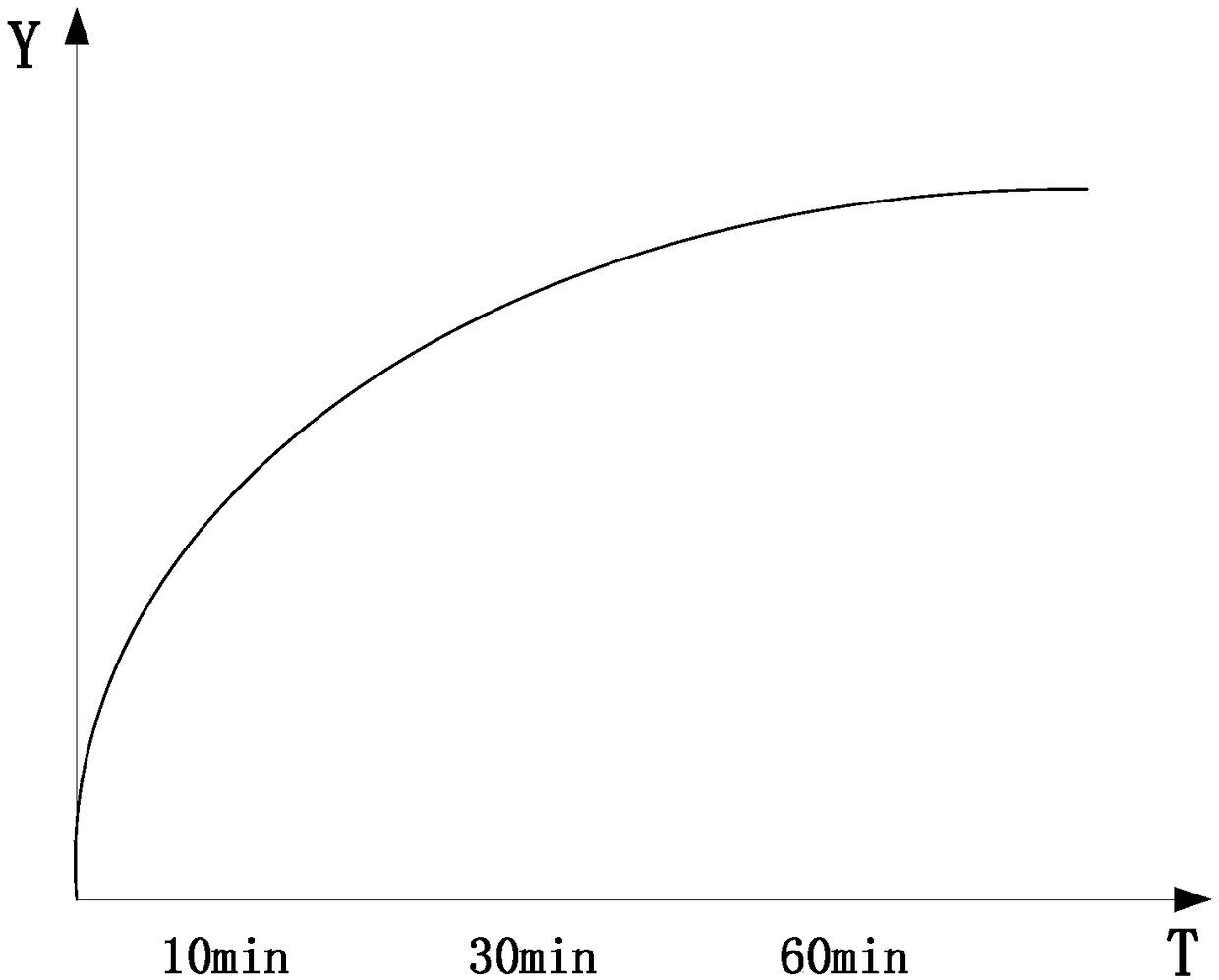

[0030] Step S20: Control the pressure in the pressure vessel through the back pressure valve set on the pressure vessel, so that the pressure in the pressure vessel is gradually reduced to the atmospheric pressure value within the first predetermined time; The back pressure valve on the pressure vessel is used to control the pressure in the pressure vessel, so that the pressure in the pressure vessel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com