Steel shell concrete structure defect detection method, steel shell concrete structure defect detection system, steel shell concrete structure defect detection apparatus, and storage medium

A concrete structure and defect detection technology, applied in the direction of measuring devices, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, using sound waves/ultrasonic waves/infrasonic waves for material analysis, etc., can solve problems such as performance degradation of steel shell concrete and reduce engineering risks , improve the overall work efficiency, and promote the effect of safe construction of the project

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

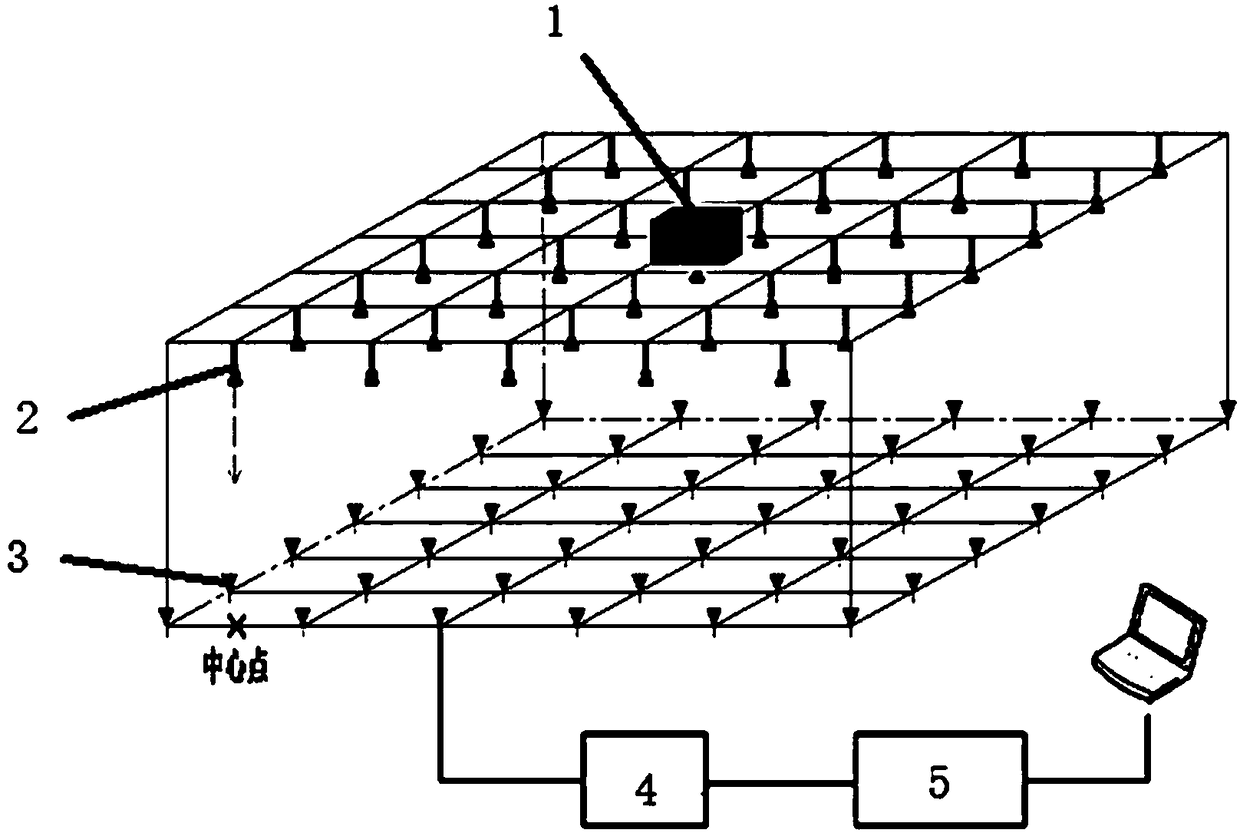

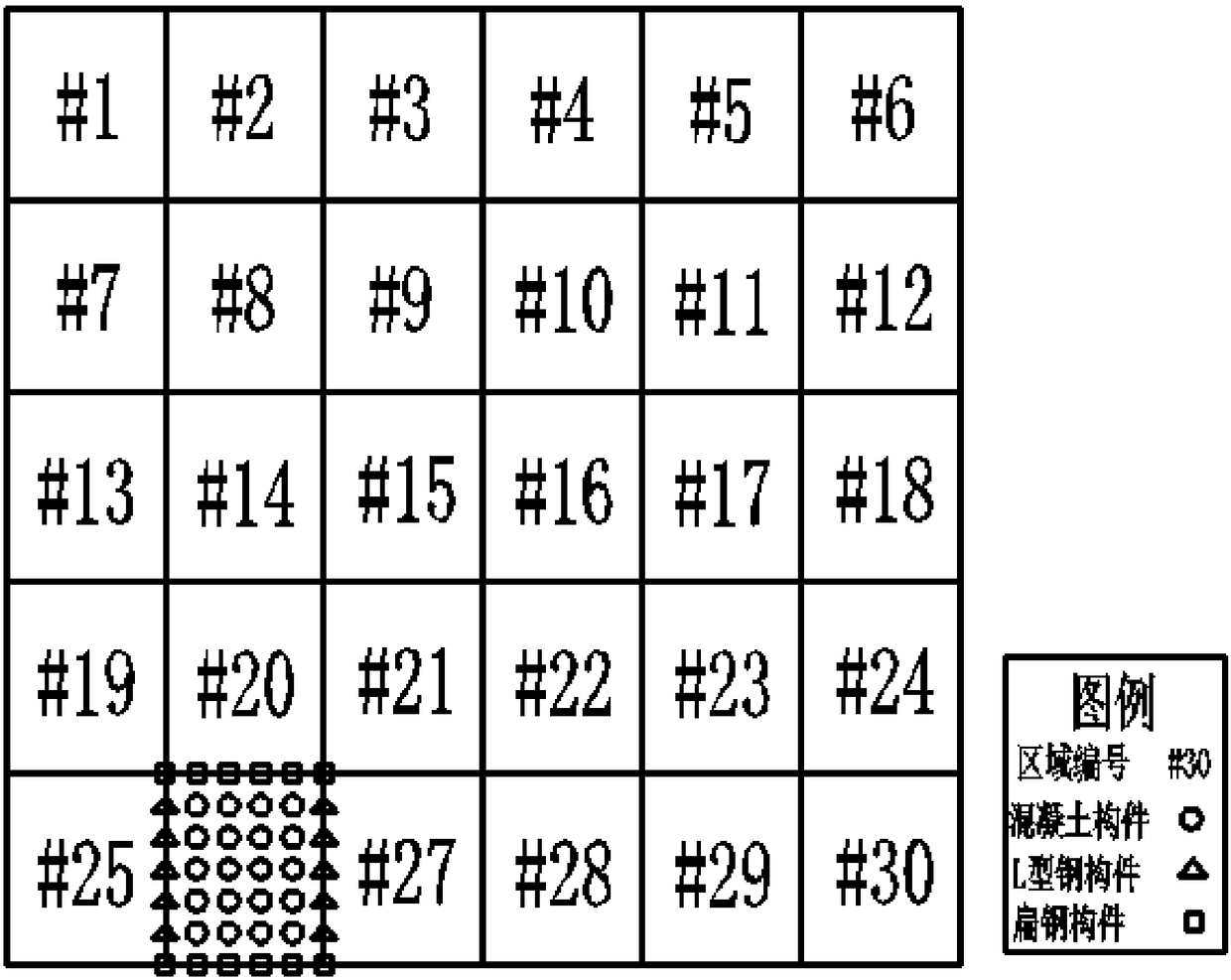

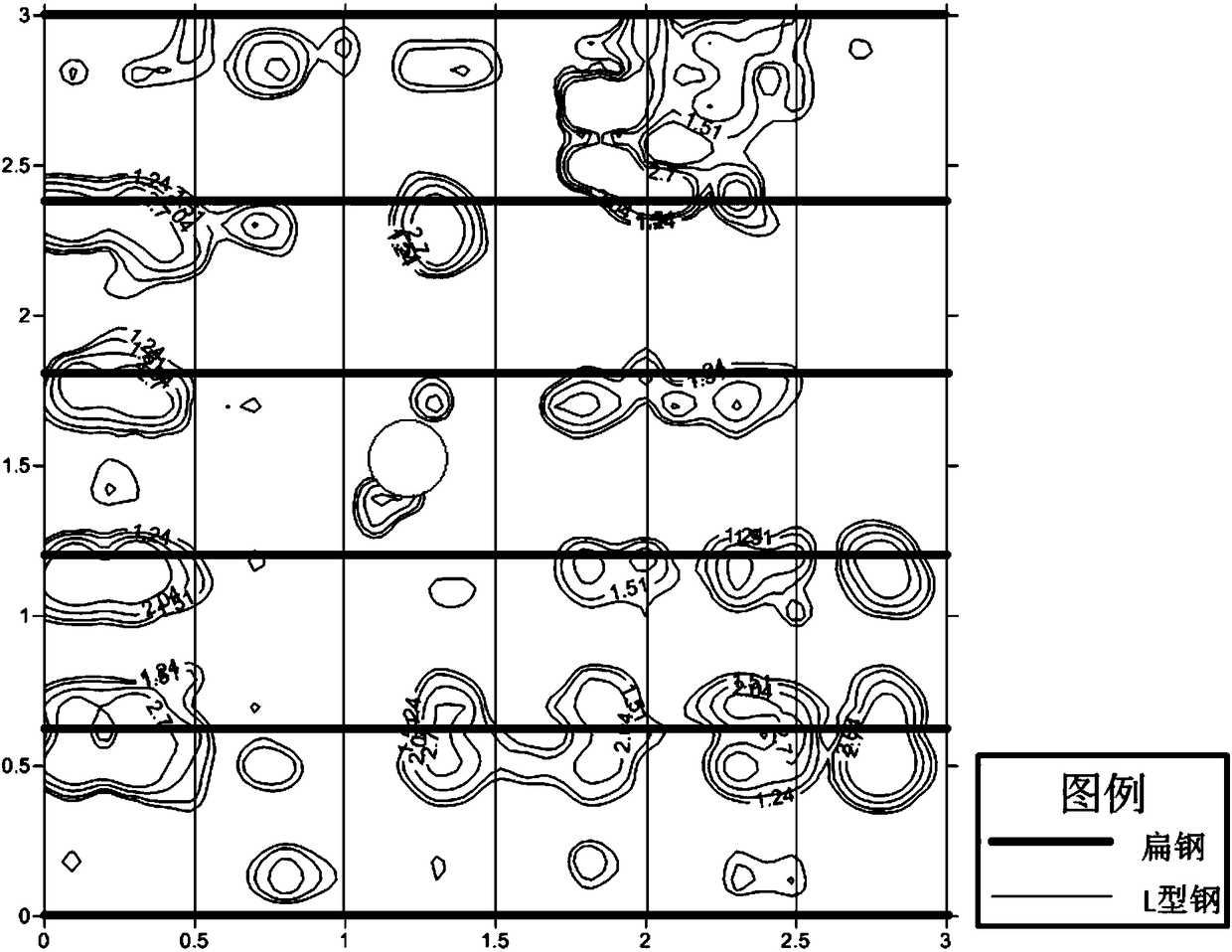

[0075] Both the geophone and the excitation hammer (vibration source) are a three-dimensional array combination structure, and the arrangement is as follows: figure 1 As shown, the size of the array is consistent with the combined structure, in this case 50cm x 60cm. In this example, the steel shell concrete structure is a steel shell concrete pipe joint, and the size of the steel shell concrete pipe joint is 3m×3m, which can be divided into 30 combined structures of the same size, as shown in figure 2 shown. Therefore, the mobile acquisition system needs to scan 30 combined structure areas to quickly complete all data acquisition in the entire area. The required number of geophones is 42, the number of excitation hammers is 35, the distance between the geophones is 10cm, and the excitation hammer is arranged at the midpoint of two adjacent geophones. The geophones have the same frequency and are velocity type geophones with a natural frequency between 100 Hz and 400 Hz, fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com