Control arm for decontamination vehicle

A control arm and decontamination technology, applied in the direction of liquid cleaning methods, chemical instruments and methods, cleaning methods and appliances, etc., can solve the problems of impact force changes, difficult equipment spraying, and affecting equipment decontamination effects, etc., to achieve Easy to change, comprehensive and even decontamination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Further detailed explanation through specific implementation mode below:

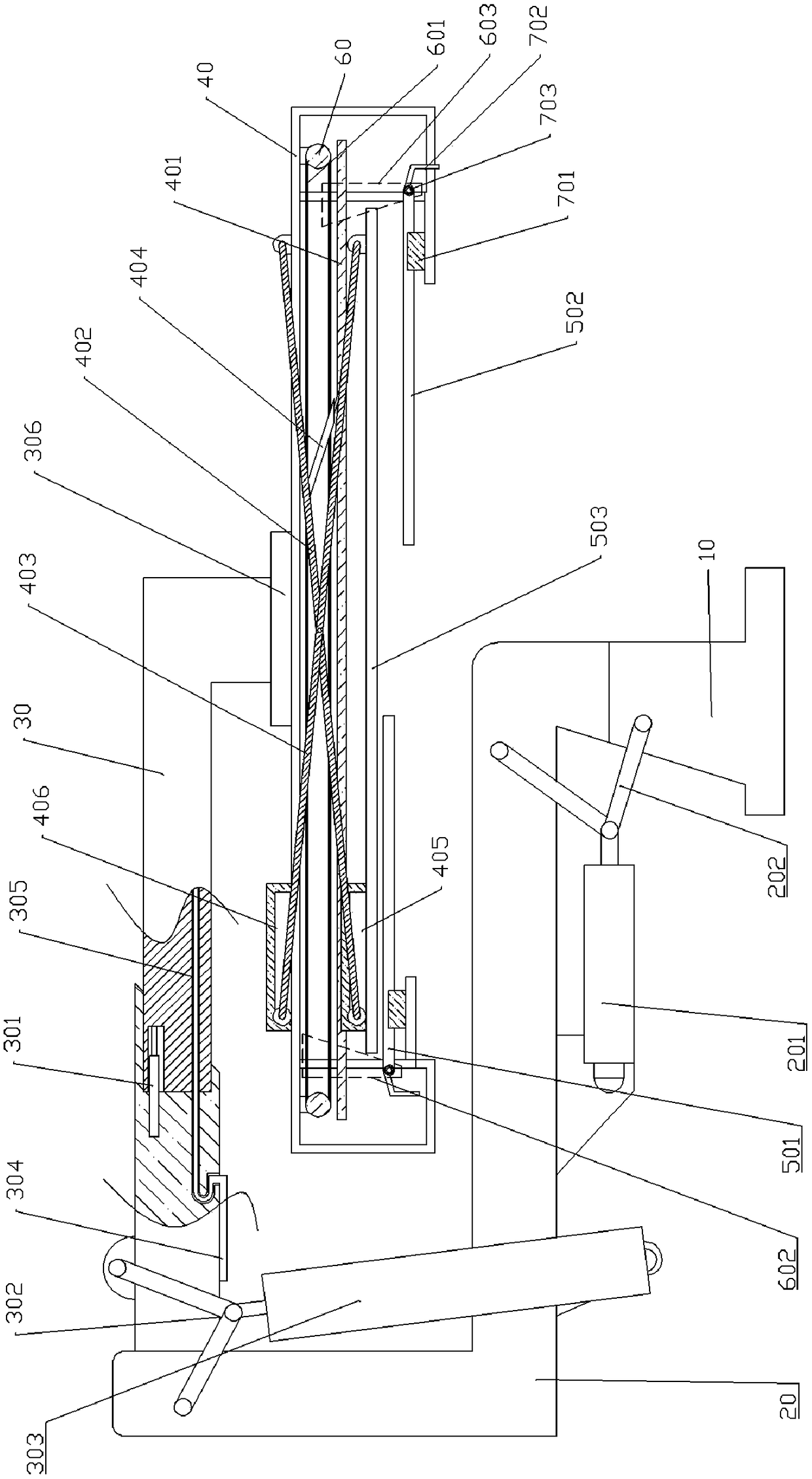

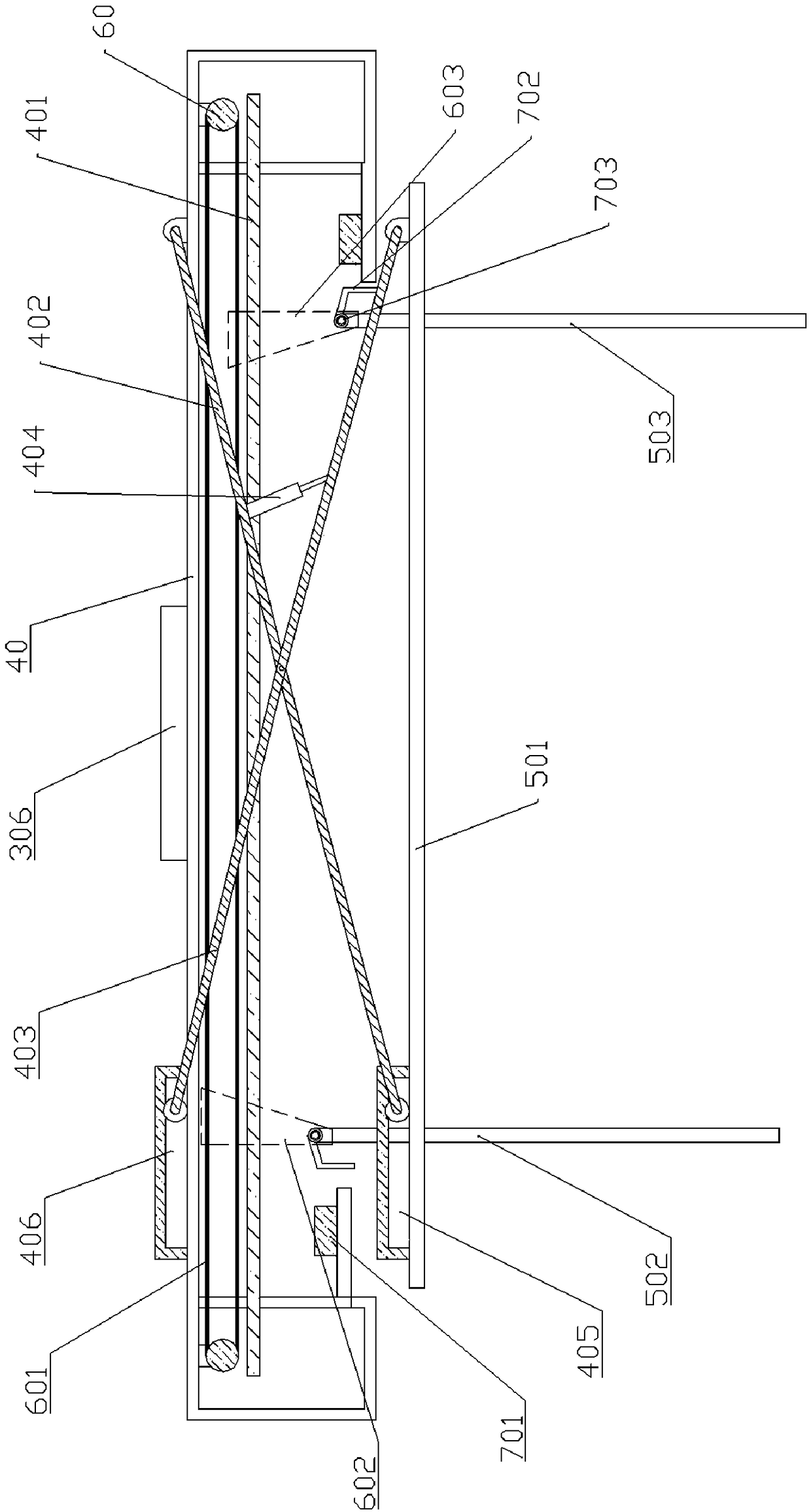

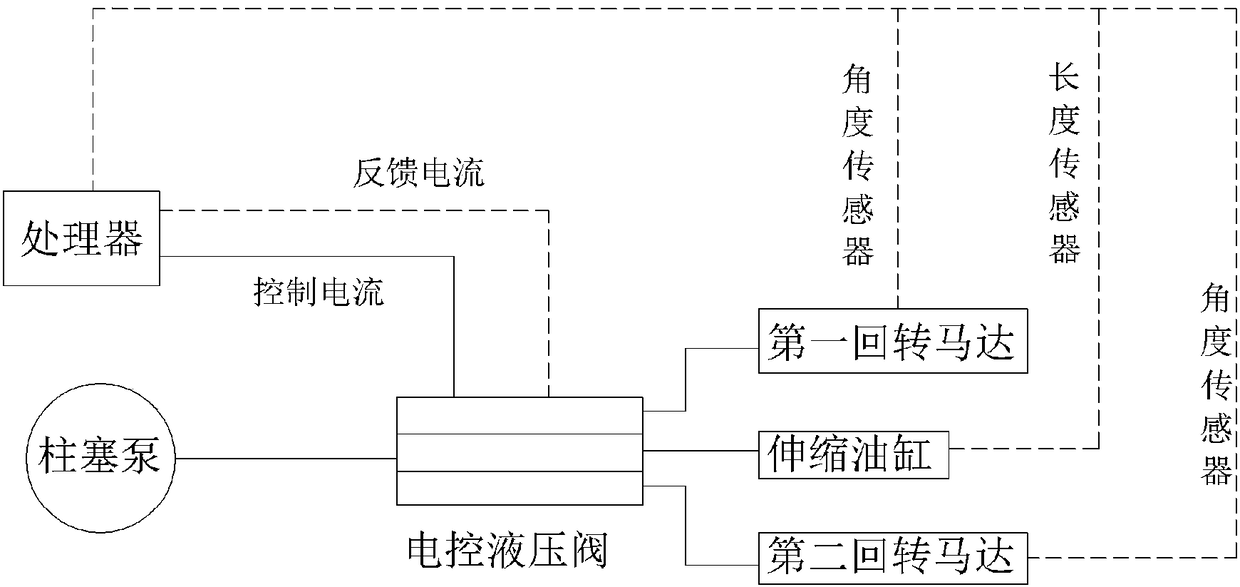

[0022] The reference signs in the drawings of the description include: support base 10, lower arm layer 20, first oil cylinder 201, first hinged rod 202, first rotary motor 203, telescopic arm layer 30, telescopic oil cylinder 301, second hinged rod 302 , the second oil cylinder 303, the water inlet pipe 304, the drag chain 305, the second rotary motor 306, the installation frame layer 40, the slide rail 401, the first connecting rod 402, the second connecting rod 403, the lifting cylinder 404, the first chute 405 , the second chute 406, the first cleaning rod 501, the second cleaning rod 502, the third cleaning rod 503, the sprocket 60, the chain 601, the first slider 602, the second slider 603, the limit block 701, the air Strut 702, spring 703.

[0023] The embodiment is basically as attached figure 1 , attached figure 2 And attached image 3 Shown: a control arm of a decontamination vehi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com