A lateral length measurement and shearing device for two-dimensional feeding of wide and thick plates and its control method

A technology of shearing device, wide and thick plate, applied in shearing device, accessories of shearing machine, manufacturing tools, etc., can solve the problems of inability to realize automatic side feeding positioning, inability to determine the relative distance of blank plates, and lower production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

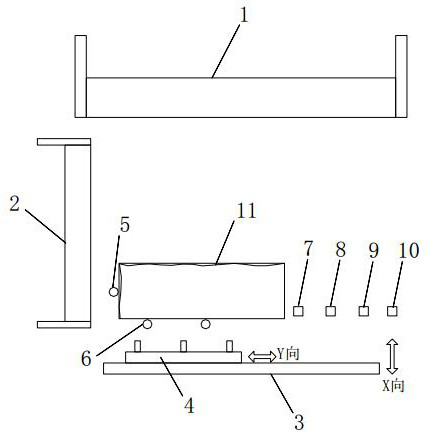

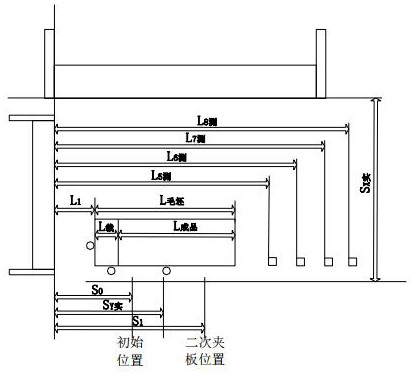

[0024] Such as figure 1 As shown, a transverse length measuring and shearing device for two-dimensional feeding of wide and thick plates includes a main shearing machine 1, a side shearing machine 2, a transverse and longitudinal two-dimensional feeding mechanism, a clamp mechanism 12, a position detection sensor, a control System, workbench, side shearing machine 2 is set on the left side of the workbench, main shearing machine 1 is set on the front side of the workbench, horizontal and vertical two-dimensional feeding mechanism is set on the back side of the workbench, and the horizontal and vertical two-dimensional feeding mechanism includes the X-axis Vertical feeder 3, Y-axis horizontal feeder 4, X-axis vertical feeder 3 is equipped with Y-axis horizontal feeder 4, Y-axis horizontal feeder 4 is equipped with a clamp mechanism 12, and one end of the upper part of the workbench is equipped with a side stop column 5 , the back gauge column 6, the other end of the top of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com