Device for achieving multi-hole tapping

A technology of installation position and tap, which is applied in the direction of tangent device, metal processing equipment, manufacturing tools, etc., can solve the problems of low production efficiency, limited test device, and position accuracy cannot be guaranteed accurately, so as to reduce the accumulation of semi-finished products, solve efficiency bottlenecks, Use a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

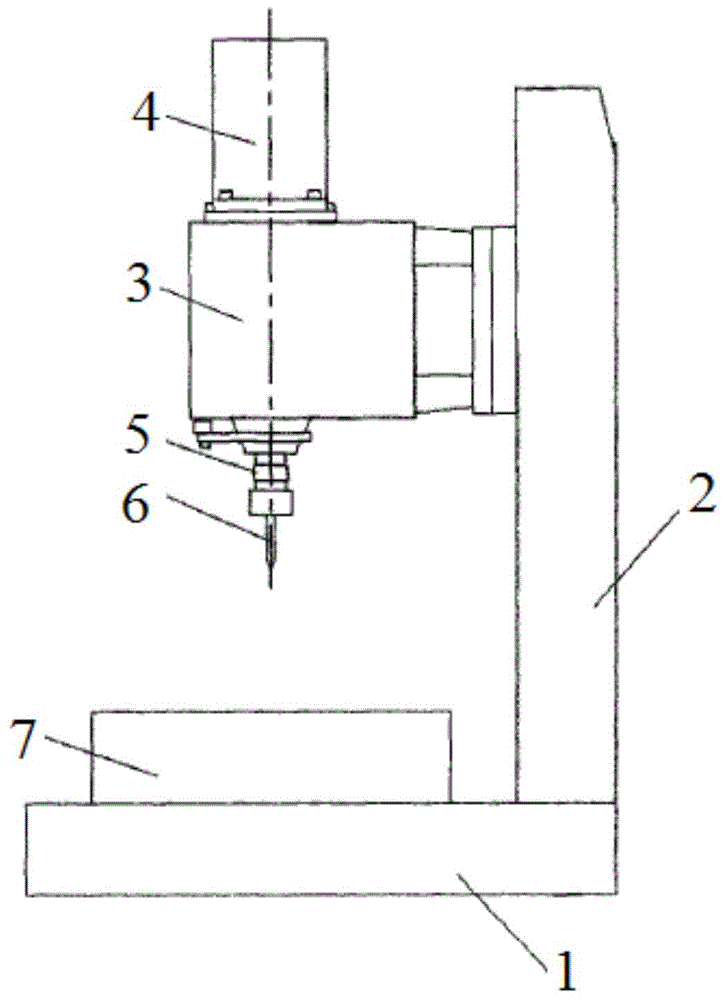

[0020] A device for realizing multi-hole tapping, its structure is as follows figure 1 As shown, it includes a base 1, a bracket 2 connected to the base 1, a main shaft 3 that moves up and down along the bracket 2, a servo motor 4 that controls the movement of the main shaft 3, the servo motor 4 changes speed through a pulley, and a tap connected under the main shaft 3 6. The center of the base 1 is also provided with a boss 7 for placing parts to be processed. The difference from the prior art solution is that, on the one hand, a plurality of taps 6 are connected below the main shaft 3; Move left and right. Specifically, the universal joint 5 is a movable plate that can be nested with each other and can move left and right. The movable plate is provided with a chute and a positioning buckle, the sliding is realized through the chute, and the position of the movable plate is fixed by the positioning buckle. Each movable plate is connected with a screw tap 6, and the install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com