Automatic dust scraping machine

An automatic, motor-driven technology, used in wood processing appliances, other plywood/plywood appliances, manufacturing tools, etc., can solve the problems of inconvenience, manual completion, low efficiency, etc., to avoid flying, ensure physical health, and improve use. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

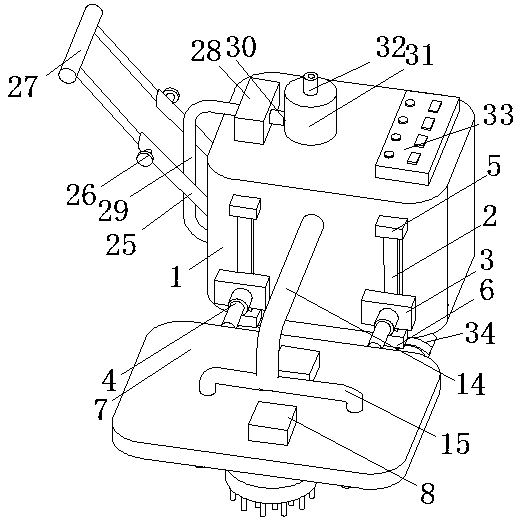

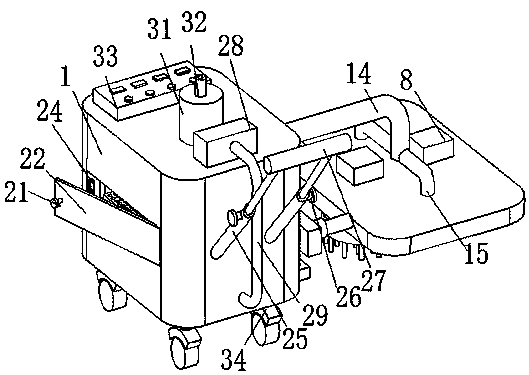

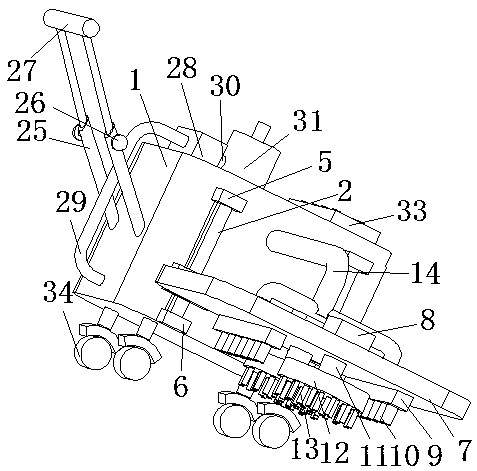

[0016] Such as Figure 1 to Figure 4 As shown, the automatic dust scraper of the present invention includes a box body 1, and the box body 1 provides a place for dust collection equipment. The front side of the box body 1 is symmetrically provided with two linear tracks 2, and the linear track 2 is a linear motor 3 with the same frequency. The up and down movement provides a platform, the outer surface of the linear track 2 is equipped with the same frequency linear motor 3, and the same frequency linear motor 3 runs to realize the adjustment of the up and down movement. The column 4 runs to realize telescopic adjustment. The upper end of the linear track 2 is provided with an upper limit block 5, which ensures the upper limit of the linear motor 3 with the same frequency. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com