Pressurized turbulent mixing device

A technology of pressurized pumps and deflectors, which is applied in the direction of fluid mixers, transportation and packaging, mixers, etc., and can solve problems such as the inability to form turbulent flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

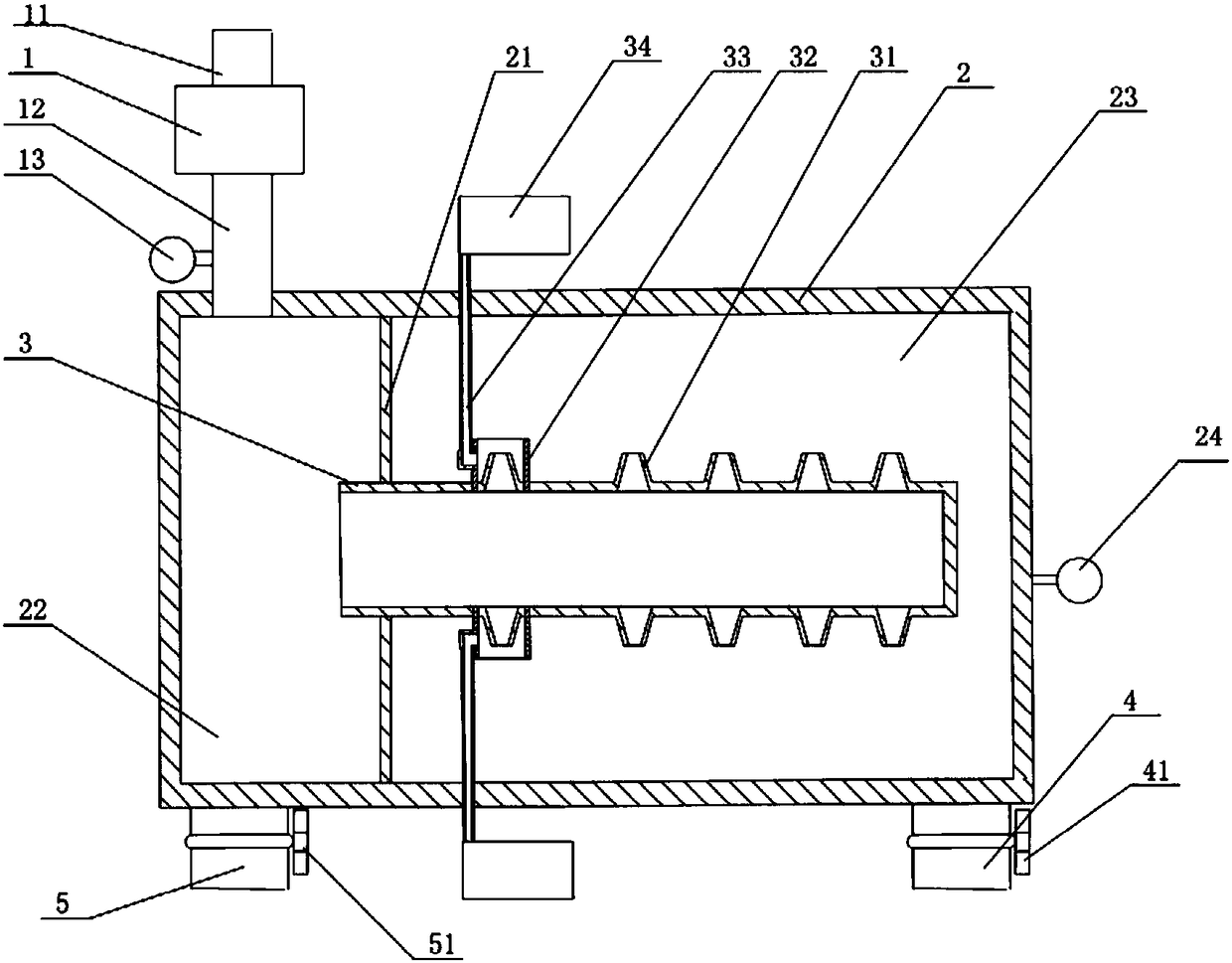

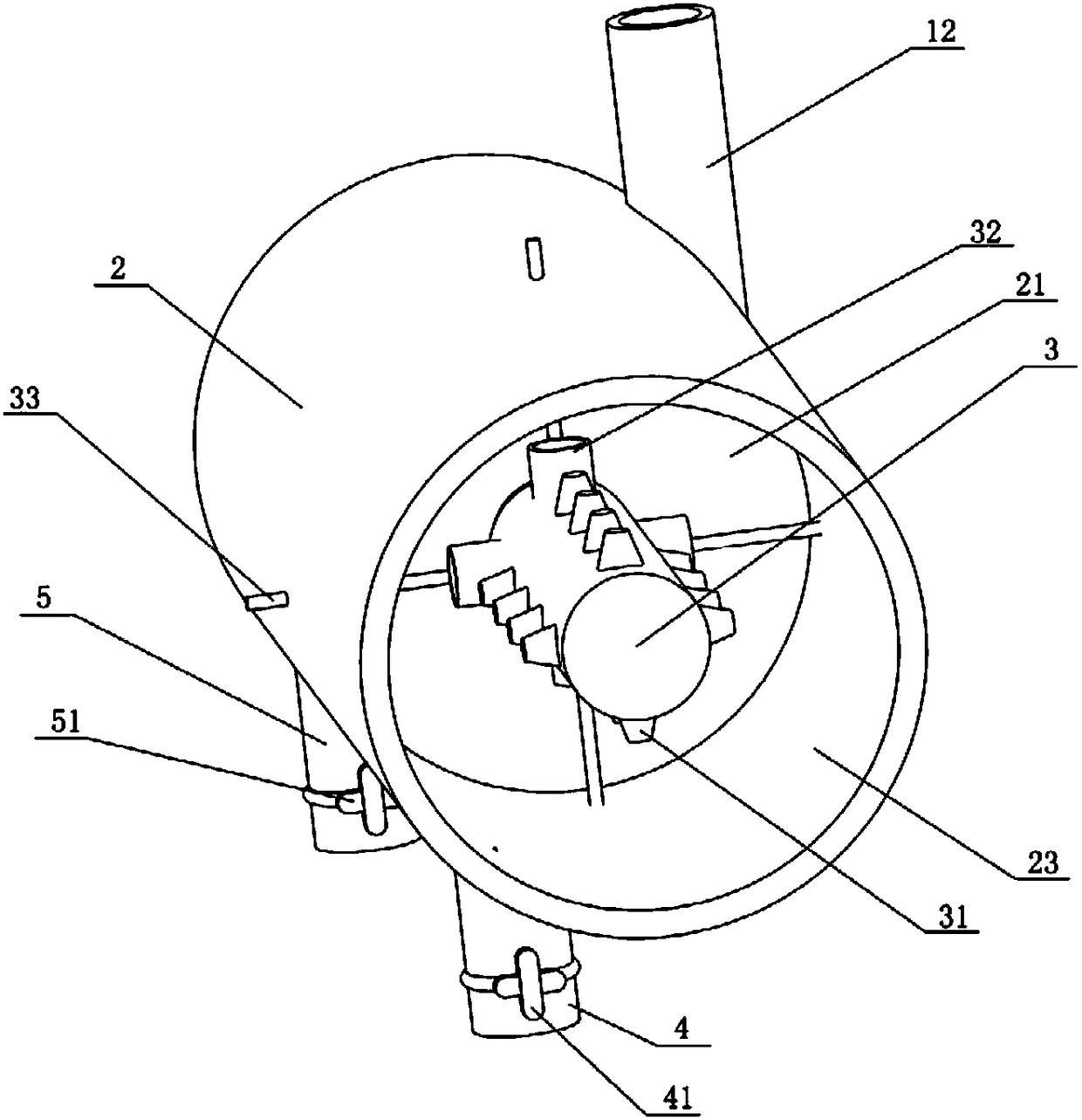

[0059] See figure 1 , figure 2 , a pressurized turbulent flow mixing device, including a pressurized pump 1, a suction pipe 11 and a liquid outlet pipe 12 arranged on the pressurized pump 1, and a cylinder 2 with both ends closed, and the inside of the cylinder 2 is A hollow tube 3 communicating with the inner cavity of the cylinder 2 is provided. The hollow tube 3 is provided with a nozzle 31 capable of spraying the inner surface of the cylinder 2. One end of the cylinder 2 is connected with the liquid outlet pipe 12, and the other end is provided with a There is output pipe 4.

[0060] Wherein, the nozzle can be a through hole or a nozzle protruding from the hollow tube.

[0061] The hollow tube communicates with the inner cavity of the column, that is, the hollow tube is provided with an opening, and the liquid in the column can enter the hollow tube through the opening.

[0062] When actually processing the liquid, the liquid to be processed enters the pressurized pump...

Embodiment 2

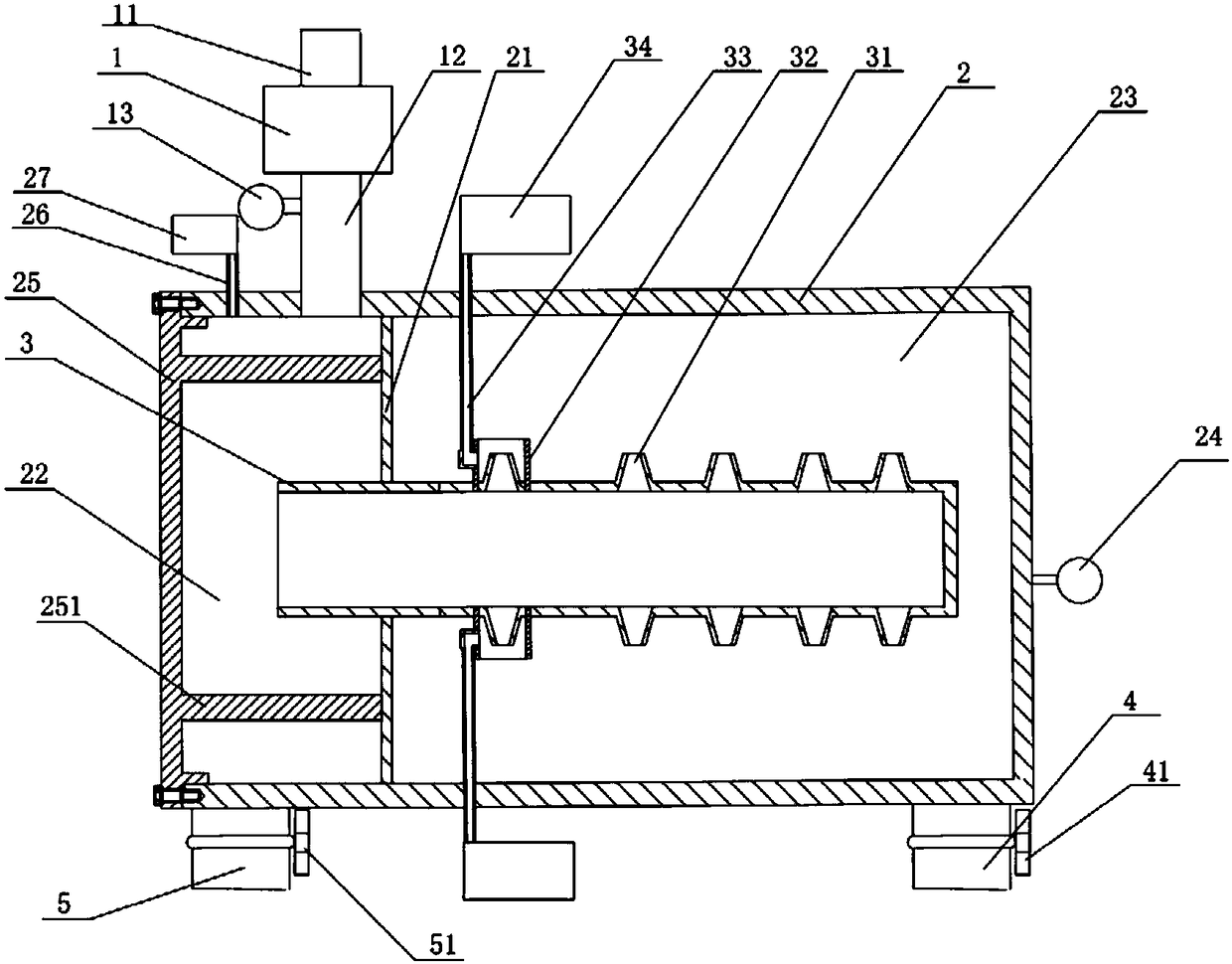

[0097] See image 3 , Figure 4 , also includes a left end cover 25, the left end cover 25 is arranged on the left end of the left chamber 22 and can make the left chamber 22 into an airtight setting, and the left end cover 25 is protruded with at least two deflectors arranged at intervals from the inner wall of the cylinder 2 251 , the deflectors 251 are distributed in a circular array with the axis of the left end cover 25 as the front, wherein one deflector 251 is arranged below the liquid outlet pipe 12 and inclined toward the liquid outlet pipe 12 . One end of the deflector 251 is fixedly connected to the left end cover 25 , and the other end is against the partition plate 21 . It also includes a vent pipe 26 and an air storage chamber 27 , the vent pipe 26 runs through the outer wall of the left chamber 22 , and one end is close to the nozzle of the liquid outlet pipe 12 , and the other end is connected to the air storage chamber 27 . All the other parts are the same a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com