Adobe wall external facade reinforcing structure and adobe wall external facade reinforcing method

A technology for strengthening structures and facades, applied in building construction, building maintenance, construction, etc., can solve the problems of inability to directly combine mortar, insufficient strength, unfavorable popularization and application, etc., to improve construction efficiency and economic benefits, and increase the use of Years, good effect of retro protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

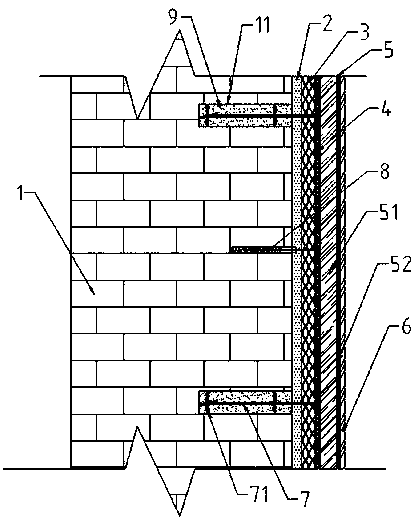

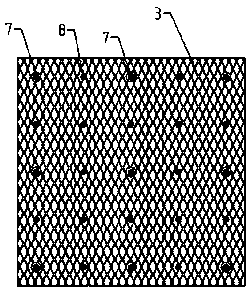

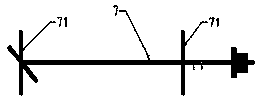

[0026] The adobe wall facade reinforcement structure provided in this embodiment includes an adobe wall 1, and the four cement slurry bases 2 of 1.5mm and 150*150*0.9mm are sequentially arranged on the facade of the adobe wall 1 from the inside to the outside. Steel wire mesh 3, 10-20mm thick cement mortar layer 4, 15mm thick plaster layer 5 and facing layer 6; the steel wire mesh 3 is a hot-dip galvanized steel wire mesh, and a plurality of vertical anchors are arranged at intervals on the steel mesh 3 The anchor rod 7 inserted into the adobe wall 1 and the bolt 8 nailed into the adobe wall 1, the steel wire mesh 3 is fixed on the adobe wall 1 through the anchor rod 7 and the bolt 8, and the anchor rod 7 and the bolt 8 distributed in a grid pattern. In specific implementation, 5% glue or methyl cellulose is added to the above-mentioned cement slurry base layer 2, both of which are viscous materials, which can improve the adhesion between the cement slurry and the adobe wall 1...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap