Detection device for pipe fitting hole distance

A detection device and hole spacing technology, which is applied in the direction of measuring device, mechanical device, mechanical measuring device, etc., can solve the problems of inability to meet the detection requirements of different pipe fittings, inability to adjust, and prone to errors, etc., to achieve easy maintenance and repair. , The effect of low manufacturing and maintenance costs, and the effect of reducing the burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

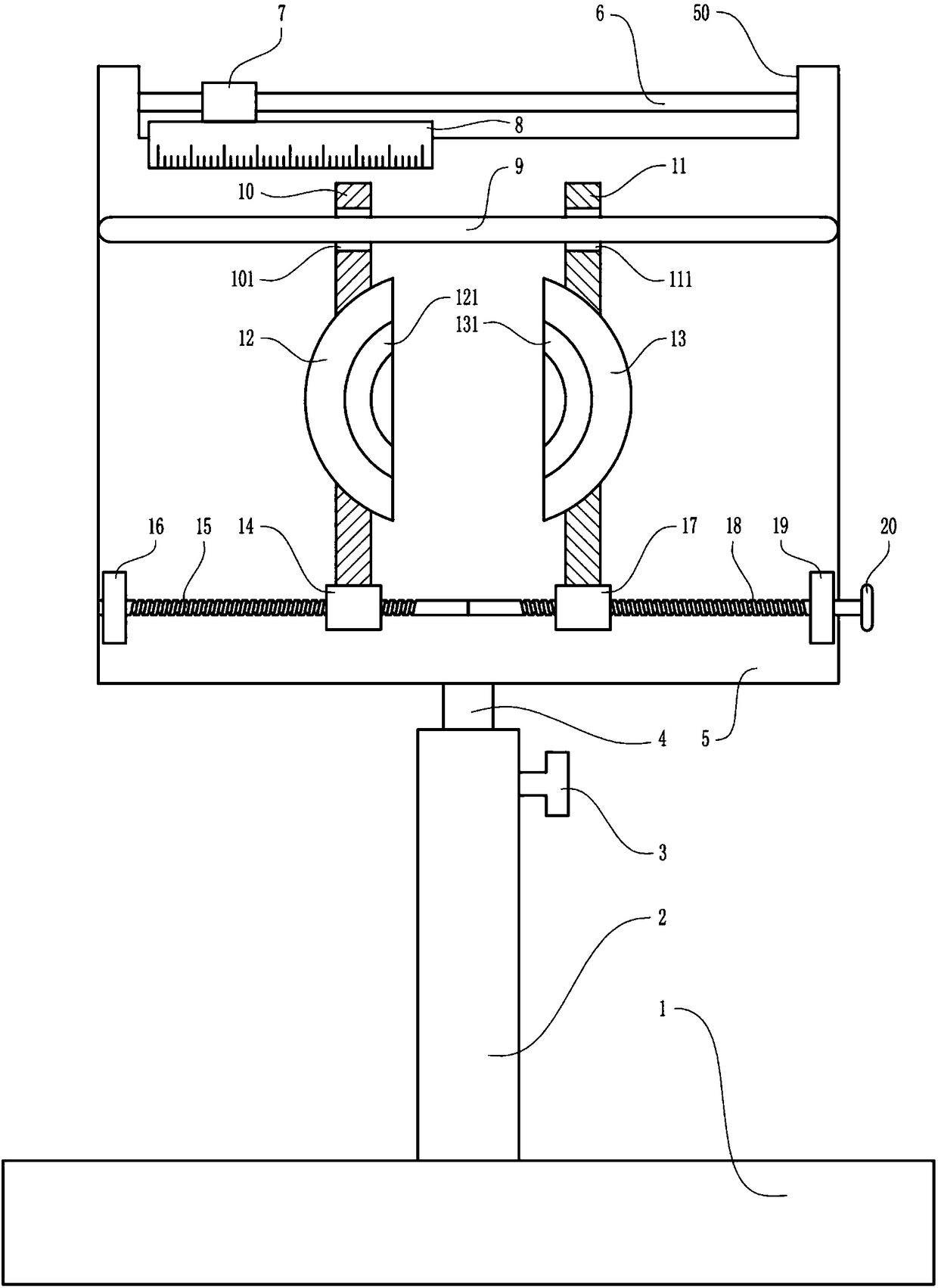

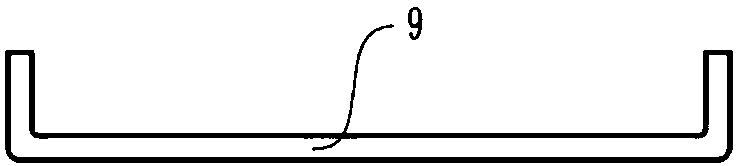

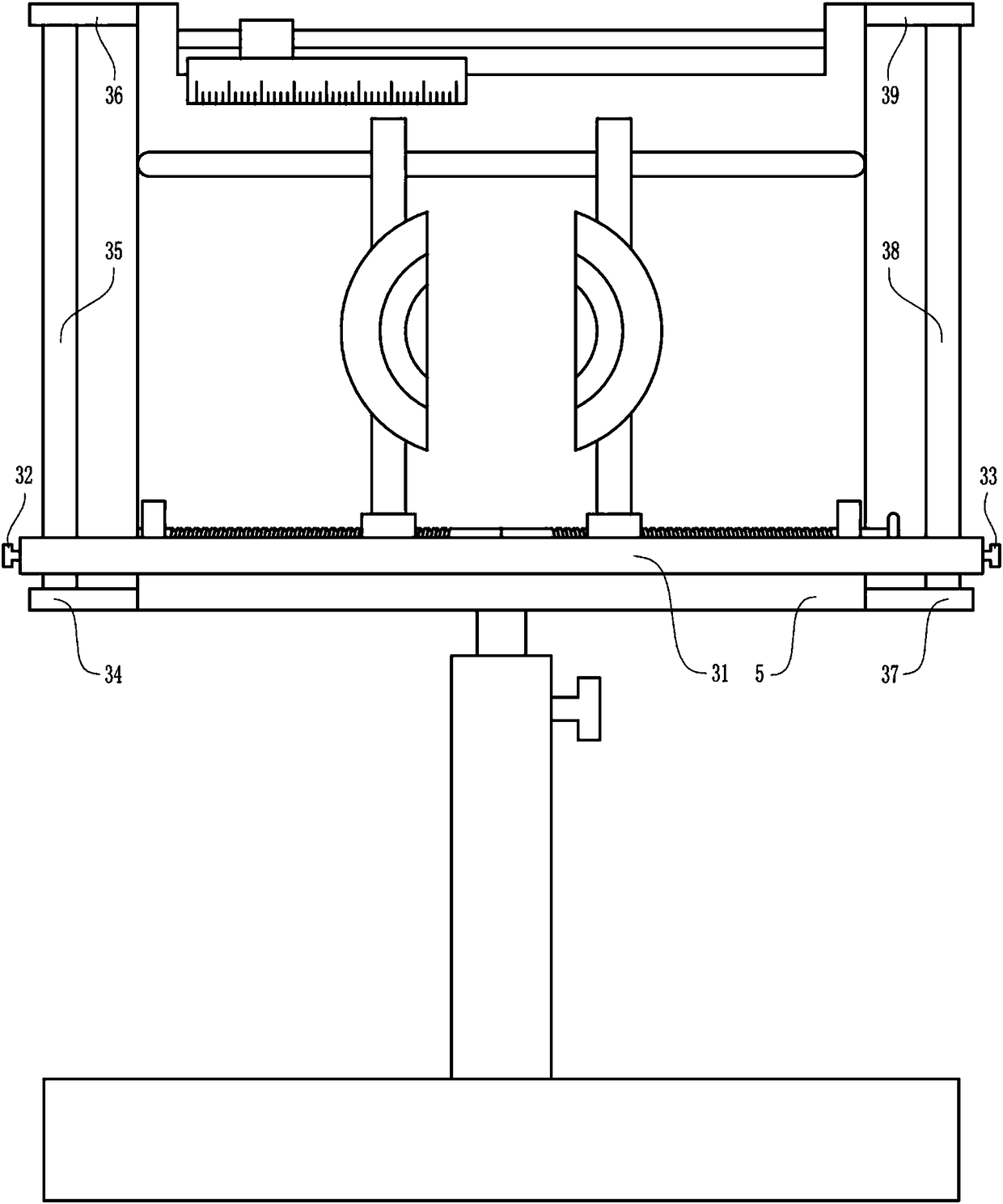

[0023] A detection device for the hole distance of pipe fittings, such as Figure 1-6As shown, it includes base 1, large casing 2, large positioning screw 3, lifting rod 4, large fixed plate 5, long guide rod 6, guide sleeve 7, scale 8, U-shaped guide rod 9, first guide plate 10. The second guide plate 11, the first arc block 12, the second arc block 13, the first nut 14, the first screw 15, the first bearing seat 16, the second nut 17, the second screw 18, The second bearing seat 19 and the rotating wheel 20, the large casing 2 is located above the base 1, the bottom of the large casing 2 is connected with the middle position of the top of the base 1, and the upper threaded connection of the right side wall of the large casing 2 has a large positioning The screw 3 and the lifting rod 4 are slidingly located in the large casing 2, the large positioning screw 3 is in contact with the lifting rod 4, the upper end of the lifting rod 4 is connected with a large fixing plate 5, and...

Embodiment 2

[0025] A detection device for the hole distance of pipe fittings, such as Figure 1-6 As shown, it includes base 1, large casing 2, large positioning screw 3, lifting rod 4, large fixed plate 5, long guide rod 6, guide sleeve 7, scale 8, U-shaped guide rod 9, first guide plate 10. The second guide plate 11, the first arc block 12, the second arc block 13, the first nut 14, the first screw 15, the first bearing seat 16, the second nut 17, the second screw 18, The second bearing seat 19 and the rotating wheel 20, the large casing 2 is located above the base 1, the bottom of the large casing 2 is connected with the middle position of the top of the base 1, and the upper threaded connection of the right side wall of the large casing 2 has a large positioning The screw 3 and the lifting rod 4 are slidingly located in the large casing 2, the large positioning screw 3 is in contact with the lifting rod 4, the upper end of the lifting rod 4 is connected with a large fixing plate 5, an...

Embodiment 3

[0028] A detection device for the hole distance of pipe fittings, such as Figure 1-6 As shown, it includes base 1, large casing 2, large positioning screw 3, lifting rod 4, large fixed plate 5, long guide rod 6, guide sleeve 7, scale 8, U-shaped guide rod 9, first guide plate 10. The second guide plate 11, the first arc block 12, the second arc block 13, the first nut 14, the first screw 15, the first bearing seat 16, the second nut 17, the second screw 18, The second bearing seat 19 and the rotating wheel 20, the large casing 2 is located above the base 1, the bottom of the large casing 2 is connected with the middle position of the top of the base 1, and the upper threaded connection of the right side wall of the large casing 2 has a large positioning The screw 3 and the lifting rod 4 are slidingly located in the large casing 2, the large positioning screw 3 is in contact with the lifting rod 4, the upper end of the lifting rod 4 is connected with a large fixing plate 5, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com