Five-axis ball-end milling geometric error compensation method

A technology of geometric error and compensation method, applied in the direction of instrument, computer control, simulator, etc., can solve the problems of lack of countermeasures, irregular change of surface processing texture, and pit marks left by the tool on the surface of the workpiece, so as to improve the processing efficiency. Accuracy and workpiece surface quality, reducing the effect of geometric errors, and ensuring the effect of workpiece texture quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

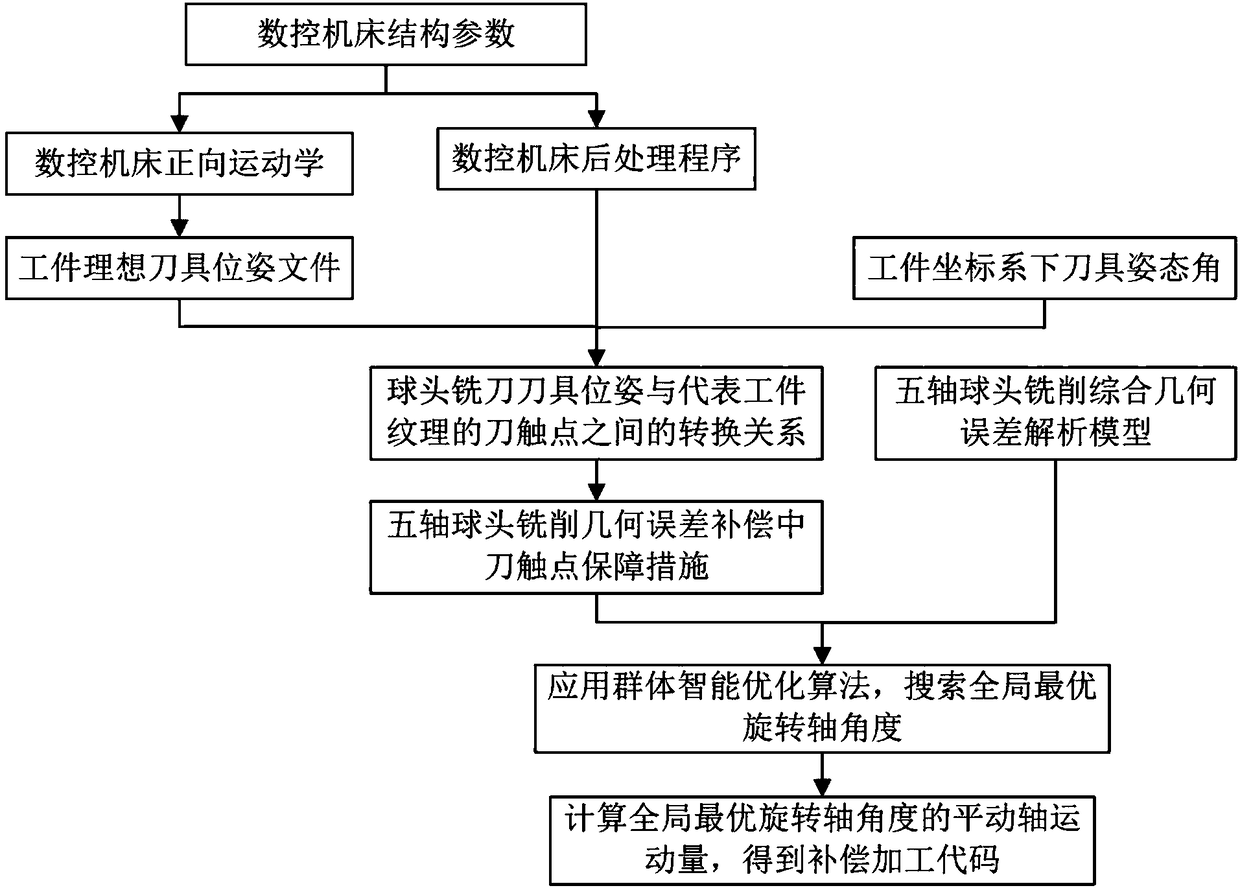

[0050] attached figure 1 Shown is a flow chart of a five-axis ball head milling geometric error compensation method of the present invention, with figure 2 The mouse-shaped workpiece is shown, and the machining of this workpiece by SmartCNC500_DRTD five-axis CNC machine tool ball-end milling is taken as an example to illustrate the geometric error compensation method of five-axis ball-end milling.

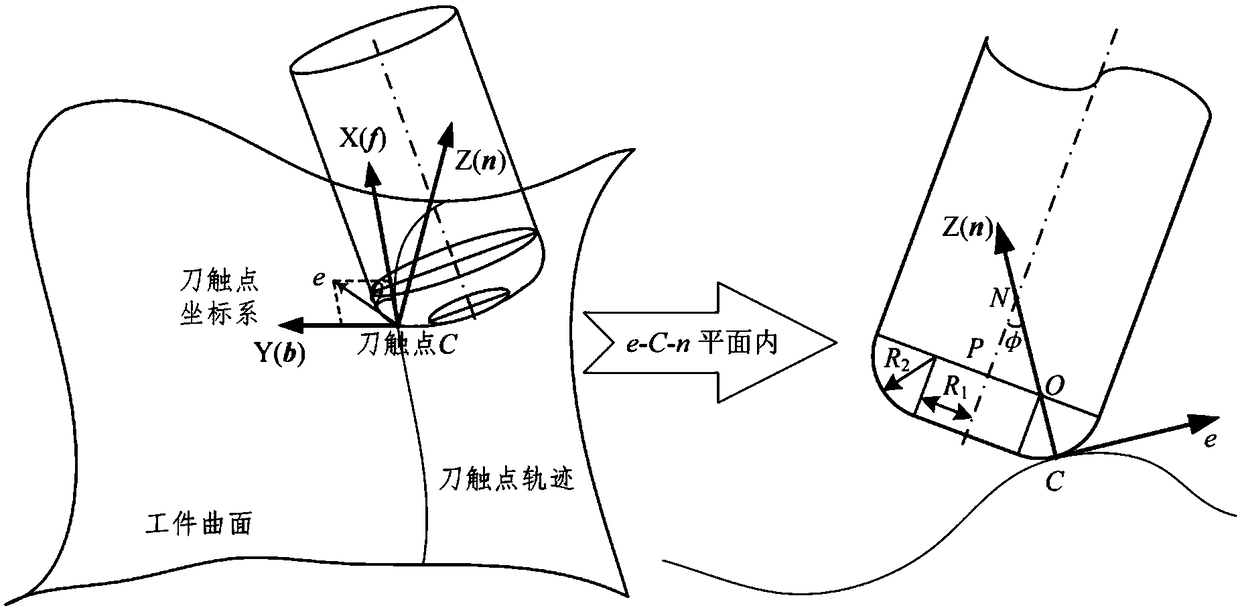

[0051]Step 1. Consider the structural parameters of the five-axis CNC machine tool. The structural parameters of the SmartCNC500_DRTD five-axis CNC machine tool are the positions of the A-axis and C-axis rotation axes in the machine tool coordinate system; establish the forward kinematics equation and post-processing program of the five-axis CNC machine tool, five The axis post-processing program proposes a dual-solution strategy for the motion of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com