Preparation method of cubic-textured nickel-based alloy base tape for non-magnetic high-temperature superconducting coated conductors

A high-temperature superconducting and coating conductor technology is applied in the field of high-temperature superconducting coated conductor metal basebands to achieve the effect of improving mechanical properties and reducing magnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

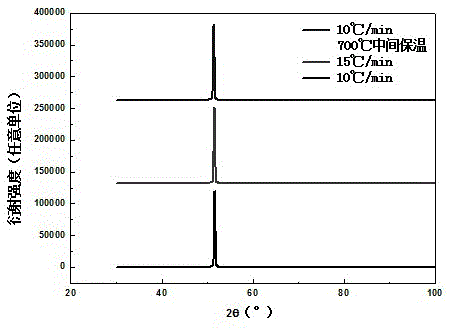

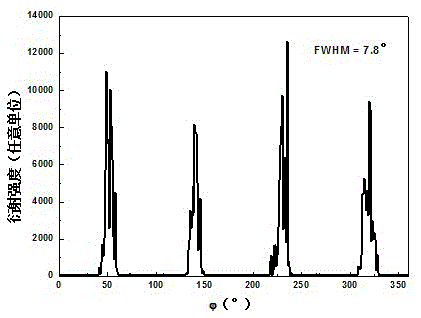

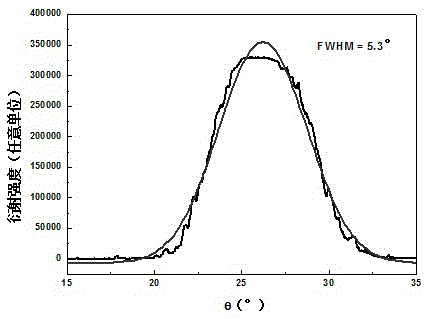

Embodiment 1

[0032] Ni, Cr, and Mo with a purity of more than 99.95% are batched according to weight percentages of 90%, 7%, and 3%. After the ingredients are fully smelted in an electromagnetic induction vacuum melting furnace, an initial billet is obtained; the obtained billet is Homogenize at 1050°C for 20 hours to make the chemical composition of the alloy more uniform, and then hot forge the ingot into a forging with a size of 44′14′14mm; heat the forging to 1050°C with the furnace for 30 minutes and then perform hot rolling. The lower amount is about 10%, and finally a hot-rolled sheet with a thickness of 4.8mm is obtained. After the hot-rolled sheet is annealed and pickled at 1050°C, it is cold-rolled with a pass reduction of 3-10% and a total reduction of 98% to obtain an alloy base strip with a thickness of 100mm. The cold-rolled base strip was ultrasonically cleaned with acetone to remove oil, and then annealed in a vacuum environment. The annealing process was to increase the te...

Embodiment 2

[0034] The Ni, Cr and Mo with a purity of more than 99.95% are batched according to the weight percentage of 90%, 7% and 3%. After the ingredients are fully smelted in an electromagnetic induction vacuum melting furnace, the initial billet is obtained; the obtained initial billet Homogenize annealing at 1050°C for 20 hours to make the chemical composition of the alloy more uniform, and then hot forge the ingot into a forging with a size of 44×14×14mm; heat the forging to 1050°C with the furnace and keep it for 30 minutes before hot rolling. The reduction is about 10%, and finally a hot-rolled sheet with a thickness of 4.8mm is obtained. After the hot-rolled sheet is annealed and pickled at 1050°C, it is cold-rolled with a pass reduction of 3-10% and a total reduction of 98% to obtain an alloy base strip with a thickness of 100mm. The cold-rolled base tape was ultrasonically cleaned with acetone to remove oil, and then annealed in a vacuum environment. The annealing process was...

Embodiment 3

[0036] The Ni, Cr and Mo with a purity of more than 99.95% are batched according to the weight percentage of 85%, 10% and 5%. After the ingredients are fully smelted in an electromagnetic induction vacuum melting furnace, the initial billet is obtained; the obtained initial billet Homogenized annealing at 1050°C for 20 hours, the chemical composition of the alloy is more uniform, and then the ingot is hot forged into a forging of 41×19×12mm; the forging is heated to 1050°C with the furnace for 30 minutes and then hot-rolled, the reduction of each pass It is about 10%, and finally a hot-rolled sheet with a thickness of 4.5mm is obtained. After the hot-rolled sheet is annealed and pickled at 1050°C, it is cold-rolled with a pass reduction of 3-10% and a total reduction of 97% to obtain an alloy base strip with a thickness of 100mm. The cold-rolled base strip is ultrasonically cleaned with acetone to remove oil, and then annealed in a vacuum environment. The annealing process is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com