Method for measuring human factor complexity of manual station in production line with consideration of cognition

A technology of complexity measurement and production line, applied in the direction of complex mathematical operations, instruments, manufacturing computing systems, etc., can solve the problems of difficult physiological data and lack of influence, and achieve the effect of comprehensive consideration, reliable and accurate correction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

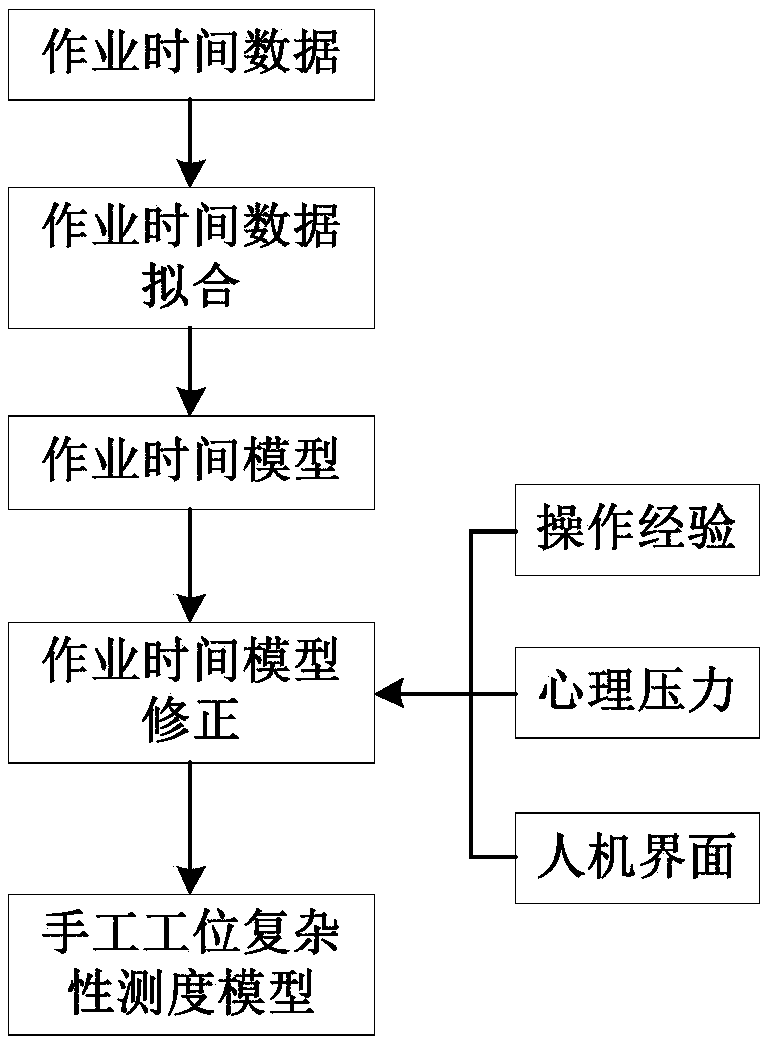

Method used

Image

Examples

Embodiment

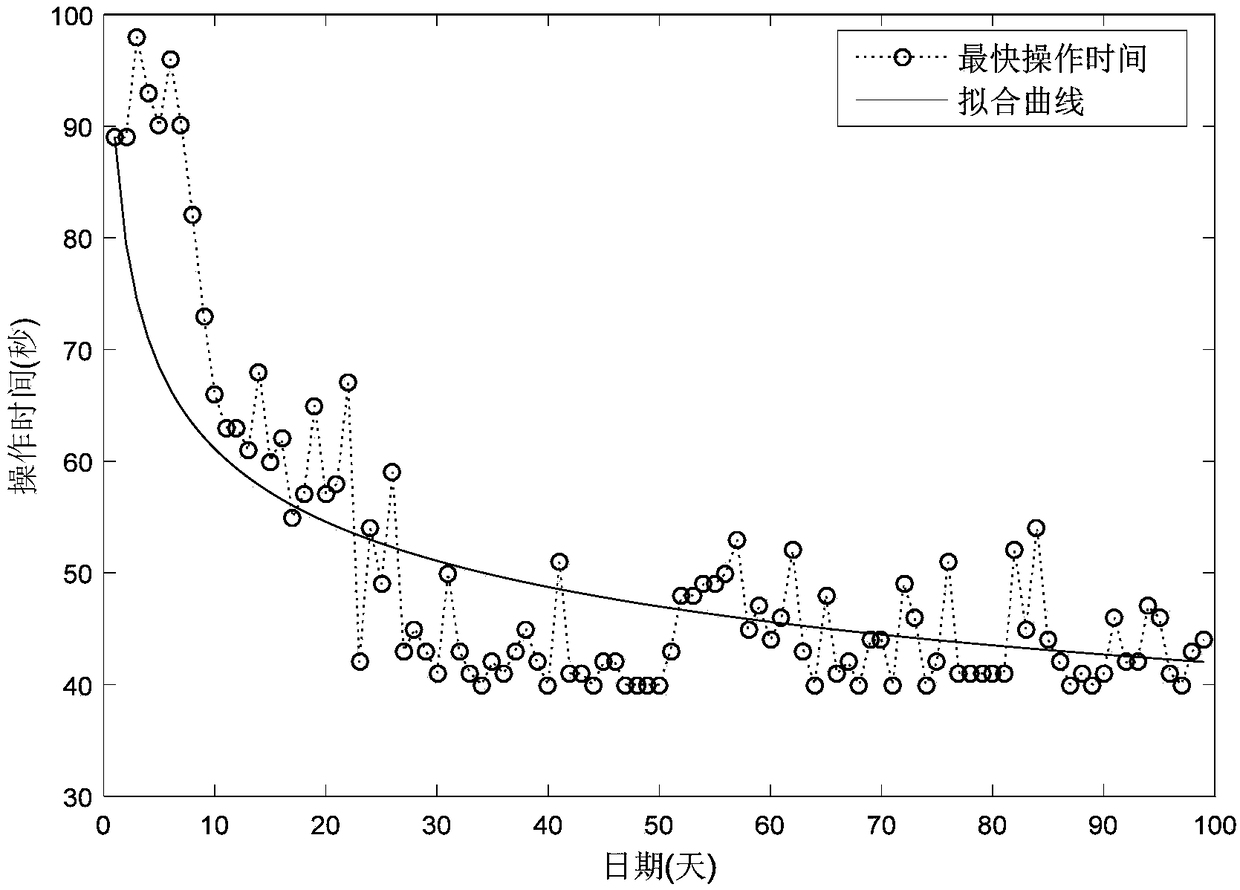

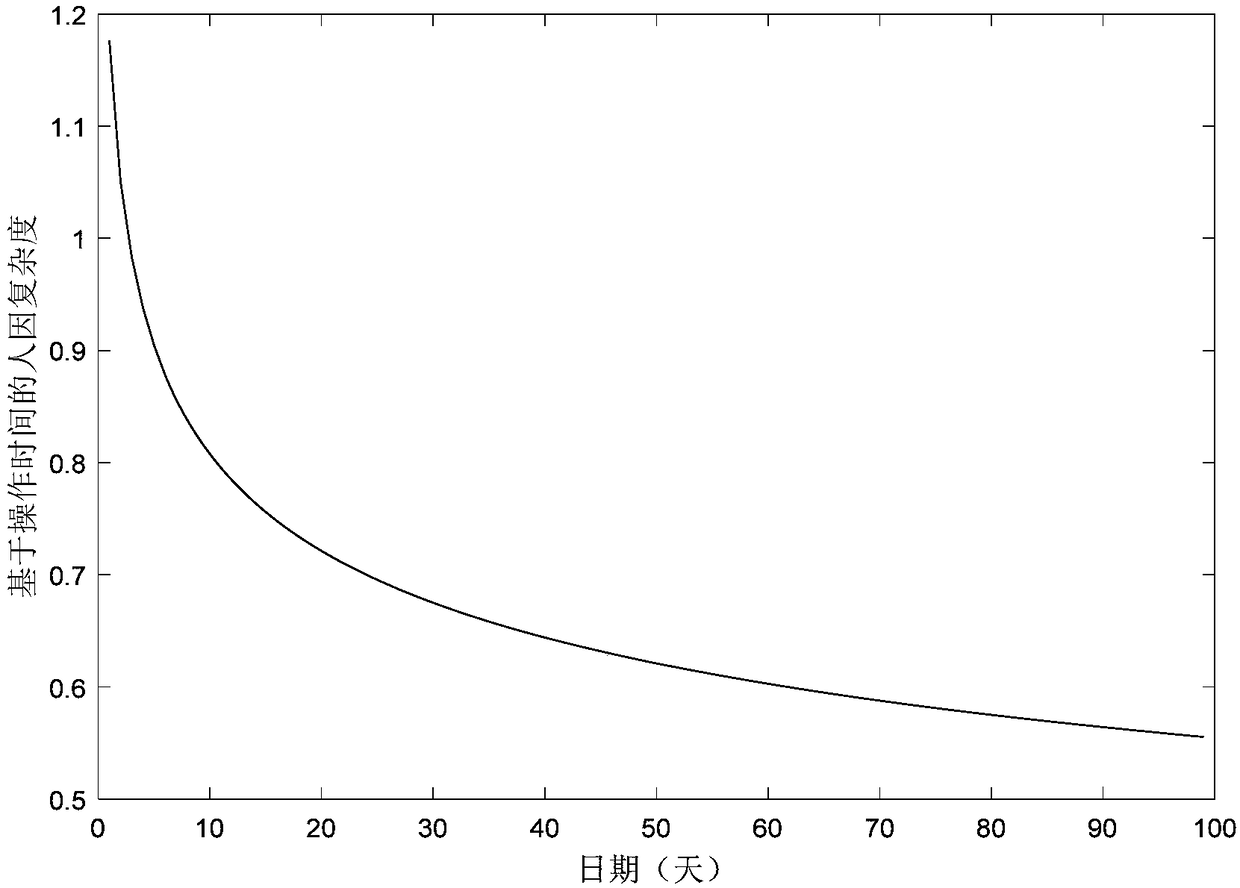

[0050]The present invention uses MATLAB to compile executable programs according to the contents of the invention. Its effect is illustrated by an example of a passenger car assembly line of a car company. Select the tightening equipment of a certain tightening station, and continuously collect the start time point and end time point of each operation of the operator within a relatively long total sample time. The shortest working time in a day is counted as the working time data of the day to measure the complexity. Table 2 shows the fastest working time of the manual station operator in a long period of time.

[0051] Table 2 The fastest working time of the manual station

[0052]

[0053]

[0054] The specific parameters of the fitting curve model are as follows:

[0055] a=89s

[0056] b=-0.2

[0057] t(x) is the shortest operating time of the operator on the xth day at the station, a is the shortest operating time of the operator on the first day during this per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com