Internal pressure monitoring device for lithium ion batteries

A lithium-ion battery, internal pressure technology, used in secondary batteries, electric traction, battery/battery traction, etc., can solve problems such as low reliability, inability to meet high-precision monitoring of battery internal pressure, and complex causes of battery internal pressure. , to achieve the effect of high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

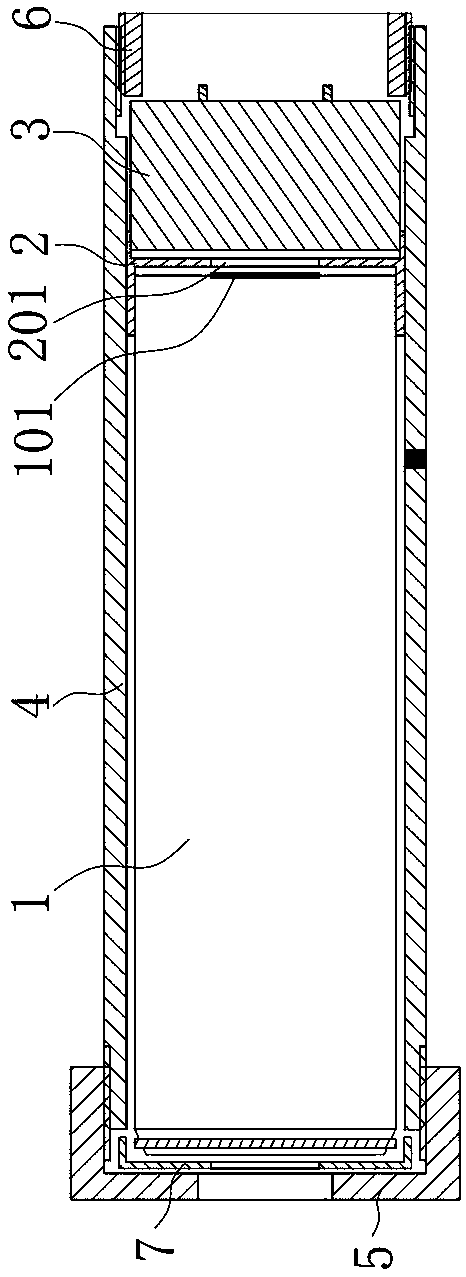

[0036] as attached figure 1 As shown, the fixing component is arranged outside the battery and the monitoring component, including the device casing 4, the nut 5 and the compression ring 6; Connection, the end close to the negative pole of the battery is connected to the compression ring, and there are insulated wire channels on the shell of the device, the middle of the nut and the middle of the compression ring, which are used to set the insulated wires to facilitate the connection of the battery and sensor with external equipment . The device housing is used to fix and assemble the battery, the nut and compression ring are used to fix the battery and monitoring components in the device housing, and the tightness between the battery and the sensor is ensured by adjusting the tightness of the nut and compression ring . In order to ensure the tightness and stability of the connection between the nut and the compression ring and the device casing, the nut and the device casin...

Embodiment 2

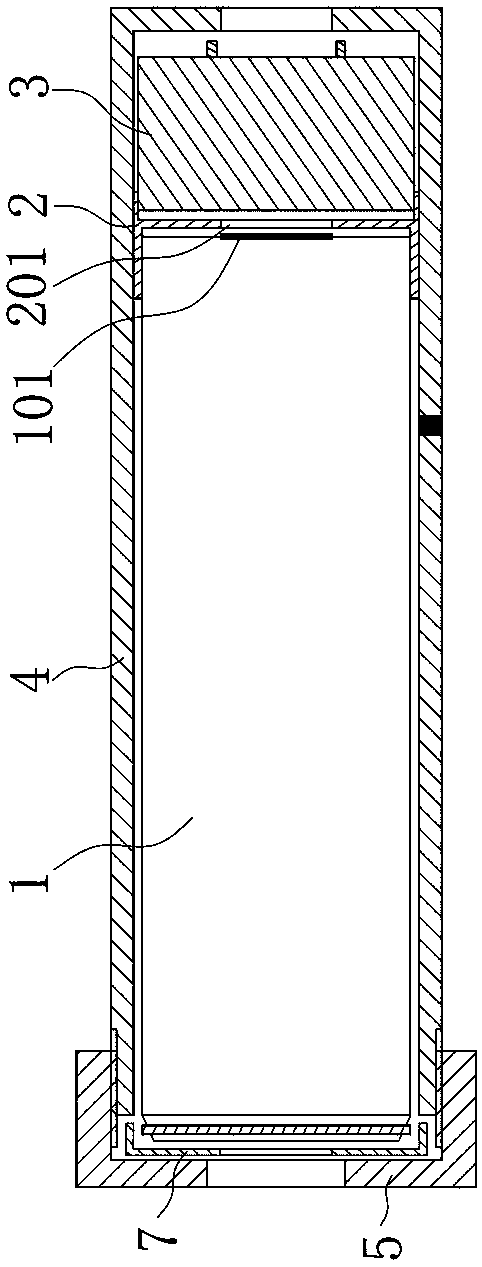

[0038] as attached figure 2 As shown, the fixing component is arranged outside the battery and the monitoring component, including the device casing 4 and the nut 5; the device casing is a cavity structure with an opening near the positive end of the battery, a thread connected to the nut, and a closed cavity near the negative end of the battery; And the middle part of the nut, the casing of the device and the middle part of the casing close to the negative end of the battery are all provided with insulated wire channels for setting the insulated wires to facilitate the connection of the battery and the sensor with the external equipment. The device casing is used to fix and assemble the battery, and the nut is used to fix the battery and monitoring components in the device casing, and the tightness between the battery and the sensor is ensured by adjusting the tightness of the nut. In order to ensure the tightness and stability of the connection between the nut and the devic...

Embodiment 3

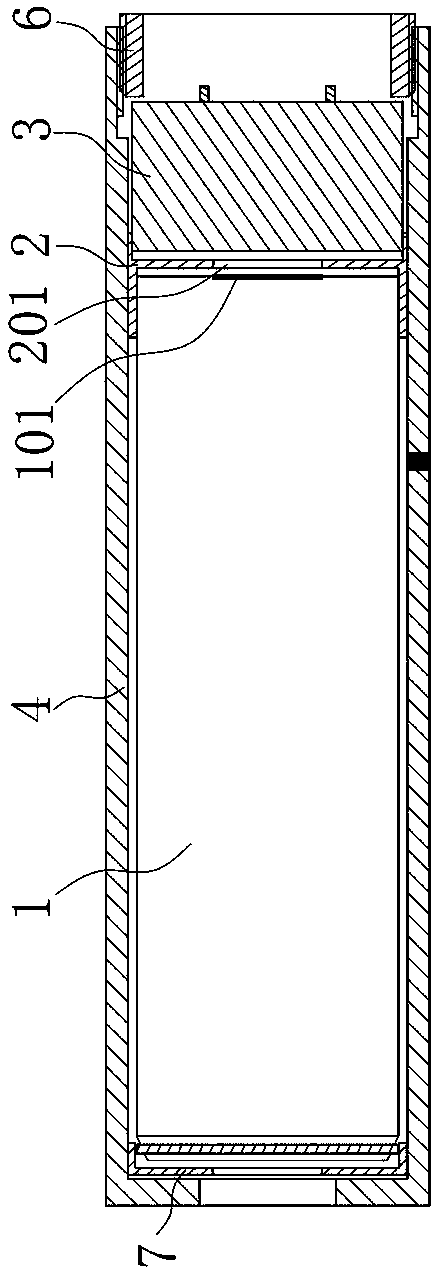

[0040] as attached image 3 As shown, the fixing component is arranged outside the battery and the monitoring component, including the device casing 4 and the compression ring 6; the device casing is an opening near the negative end of the battery, provided with threads to connect with the compression ring, and a closed cavity near the positive end of the battery structure; and the middle part of the compression ring, the device casing and the middle part of the casing near the positive end of the battery are all provided with insulated wire channels for setting insulated wires to facilitate the connection of the battery and sensors with external equipment. The device casing is used to fix and assemble the battery, and the compression ring is used to fix the battery and monitoring components in the device casing, and the tightness between the battery and the sensor is ensured by adjusting the tightness of the compression ring. In order to ensure the tightness and stability of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com