Intelligent electric control pressure electromagnetic valve

A solenoid valve and electronic control technology, applied in the field of pressure solenoid valve, can solve the problems of solenoid valve damage, decrease in insulation performance, affecting the service life of solenoid valve, etc., and achieve the effect of reasonable structure and accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

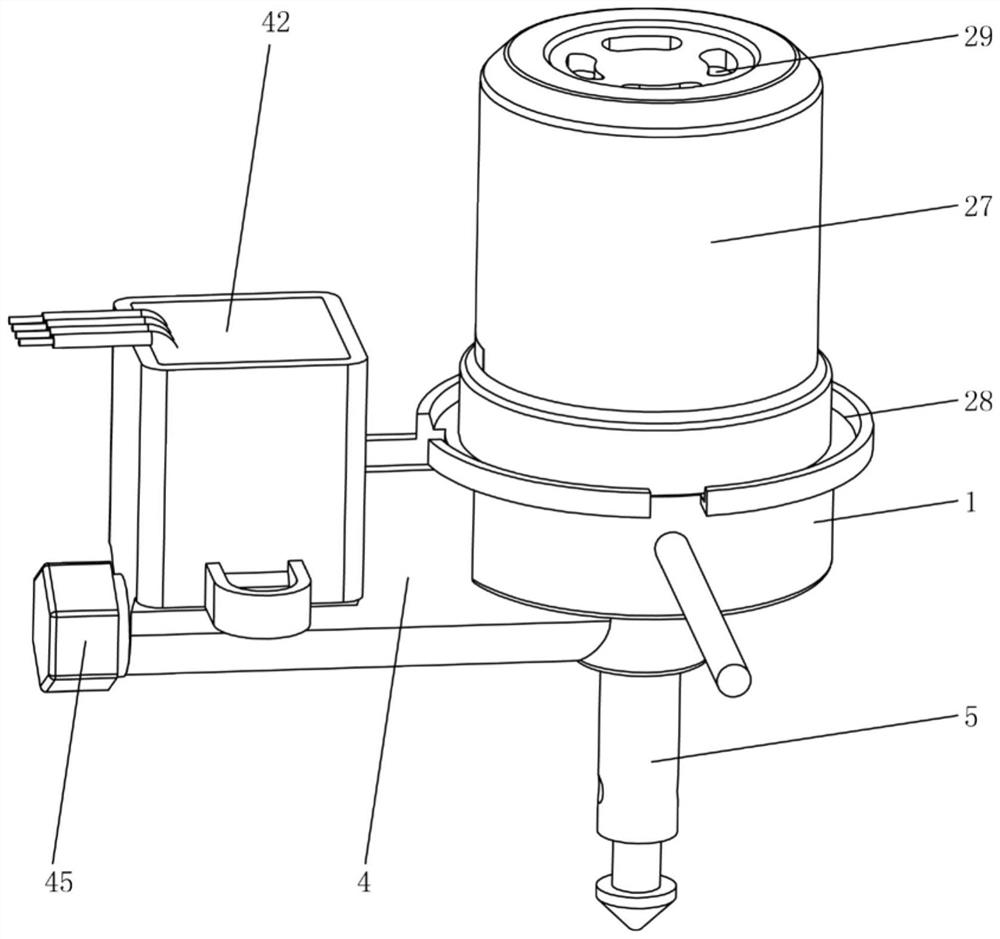

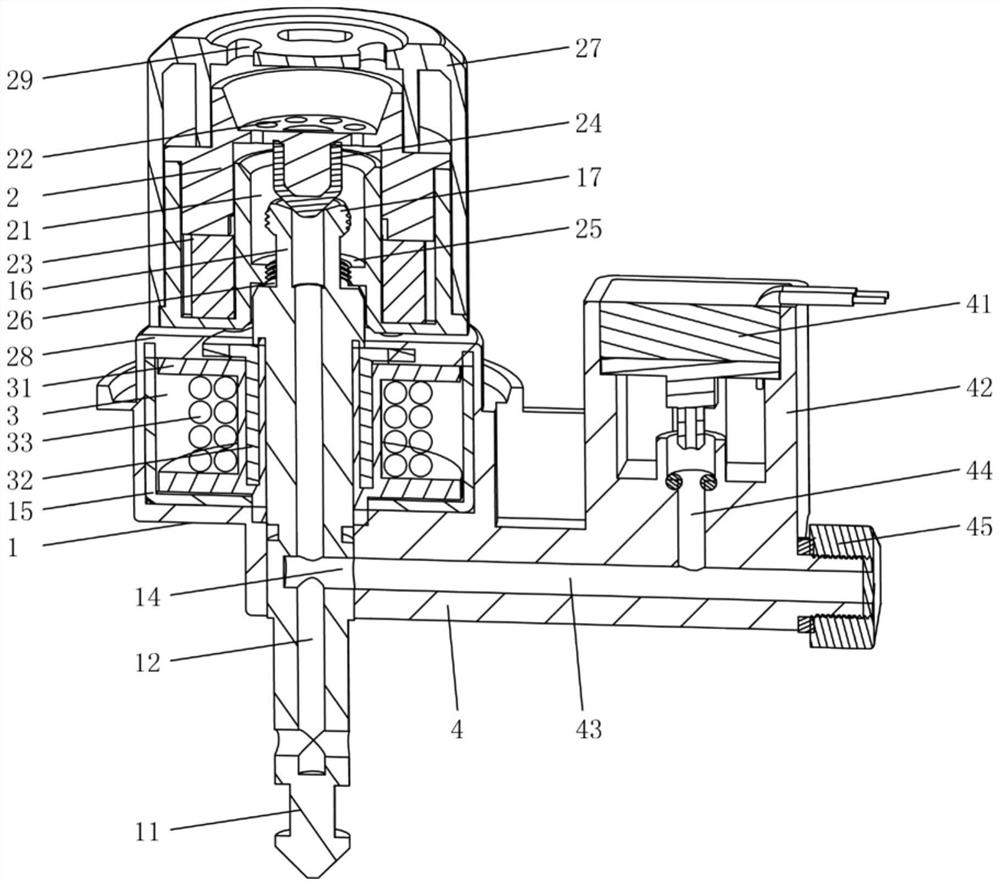

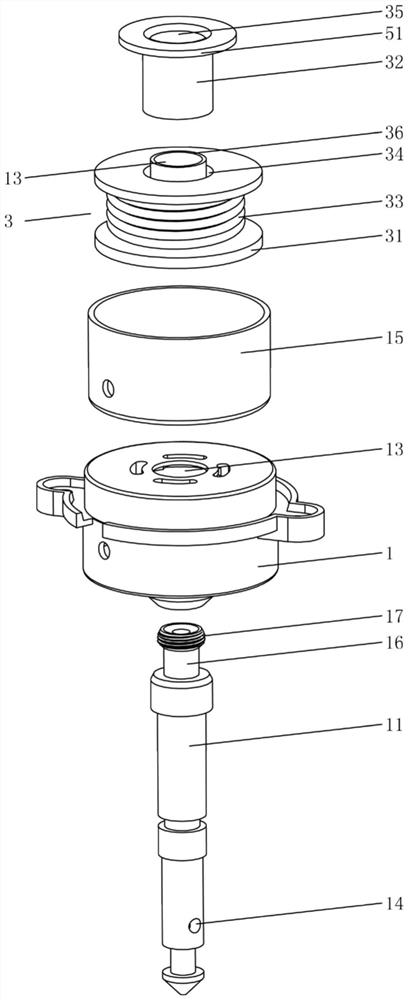

[0023] The technical solutions of the present invention will be described below with reference to the accompanying drawings and embodiments.

[0024] like Figure 1-5 As shown in the figure, an intelligent electronically controlled pressure solenoid valve according to the present invention includes a valve body 1, a gas valve stem 11 and a pressure cover 2, the valve body 1 is provided with a passage hole 13, and the gas valve stem 11 passes through the The passage hole 13 is fixedly connected with the valve body 1, and the gas valve rod 11 is provided with a pressure relief hole 12; the pressure cover 2 is movably mounted on the upper end of the gas valve rod 11, and the valve body 1 is provided with an electromagnetic assembly 3. The pressure cover 2 is provided with a permanent magnet 23; the lower end of the valve body 1 is provided with a pipe joint 4, one end of the pipe joint 4 is connected with the gas valve stem 11, and the pipe joint 4 is communicated with the pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com