Molded article and molding method thereof

A technology for forming products and forming molds, applied in chemical instruments and methods, layered products, tubular articles, etc., can solve problems such as difficulty in dispersion, and achieve the effect of improving tensile elastic modulus and suppressing bending elastic modulus.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

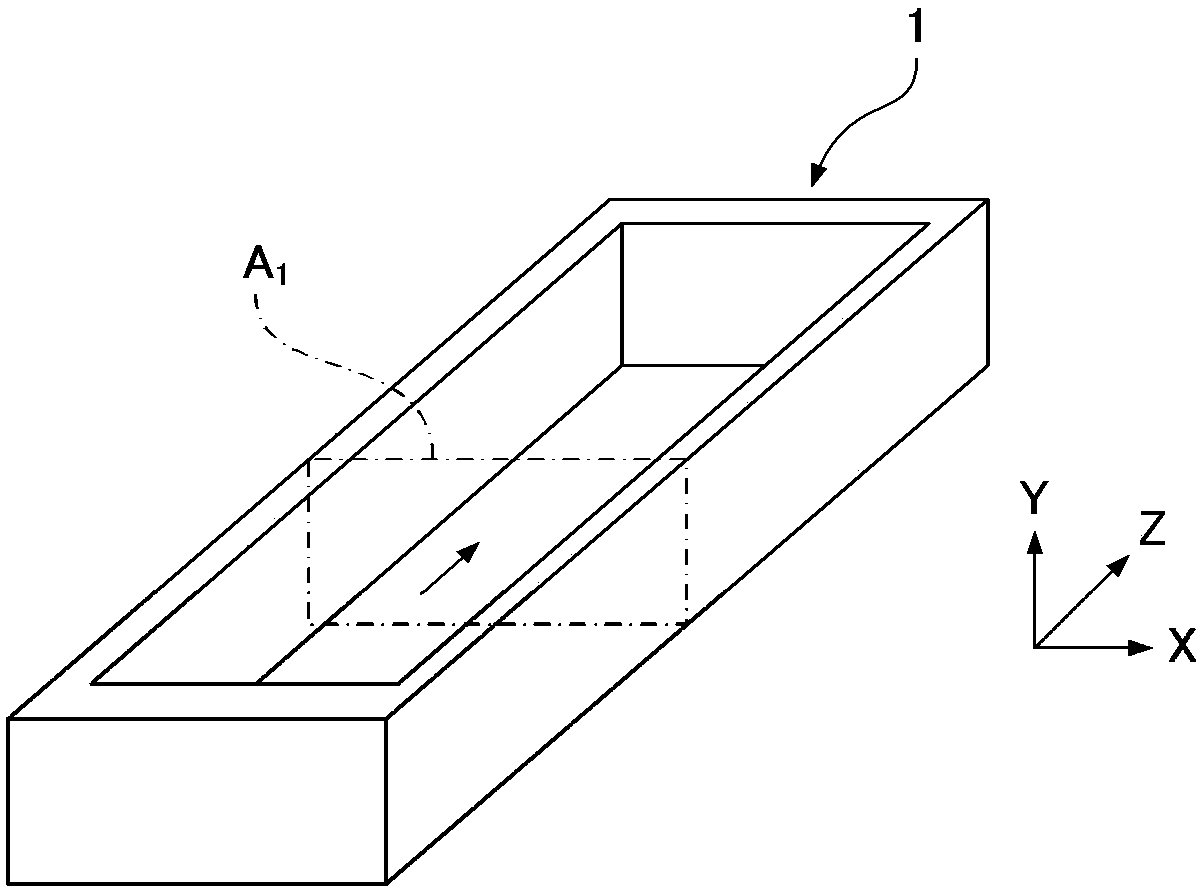

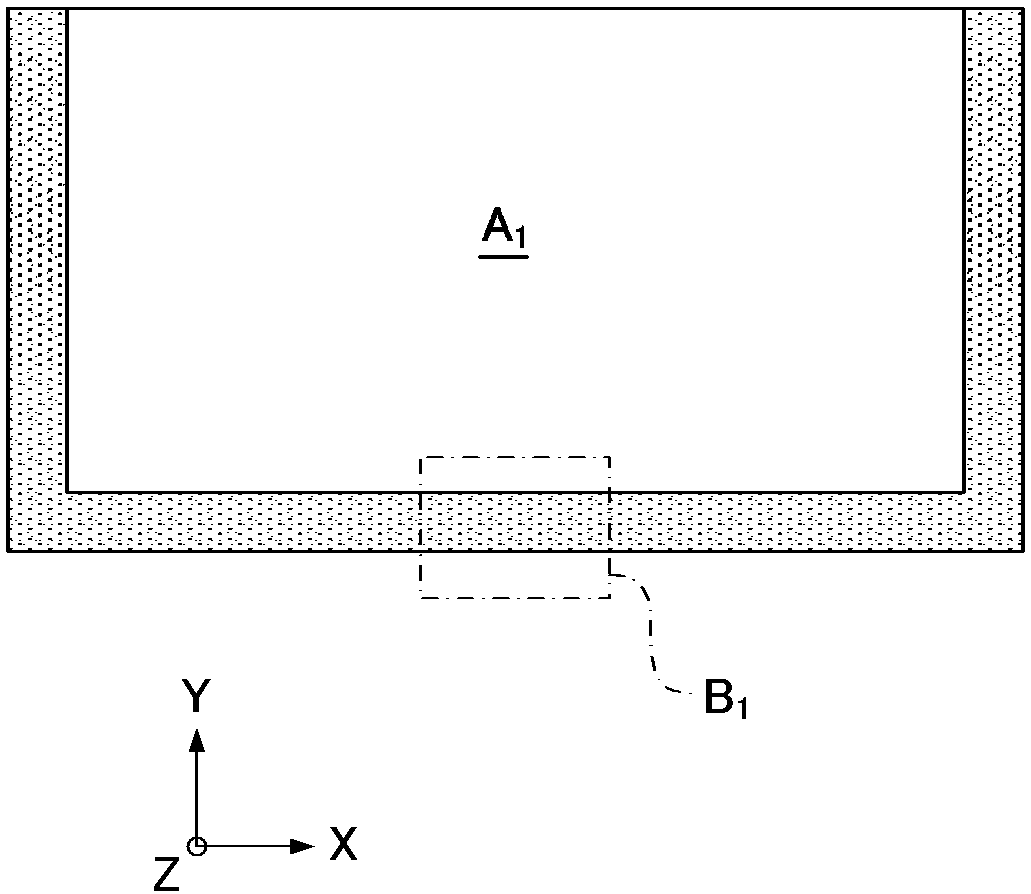

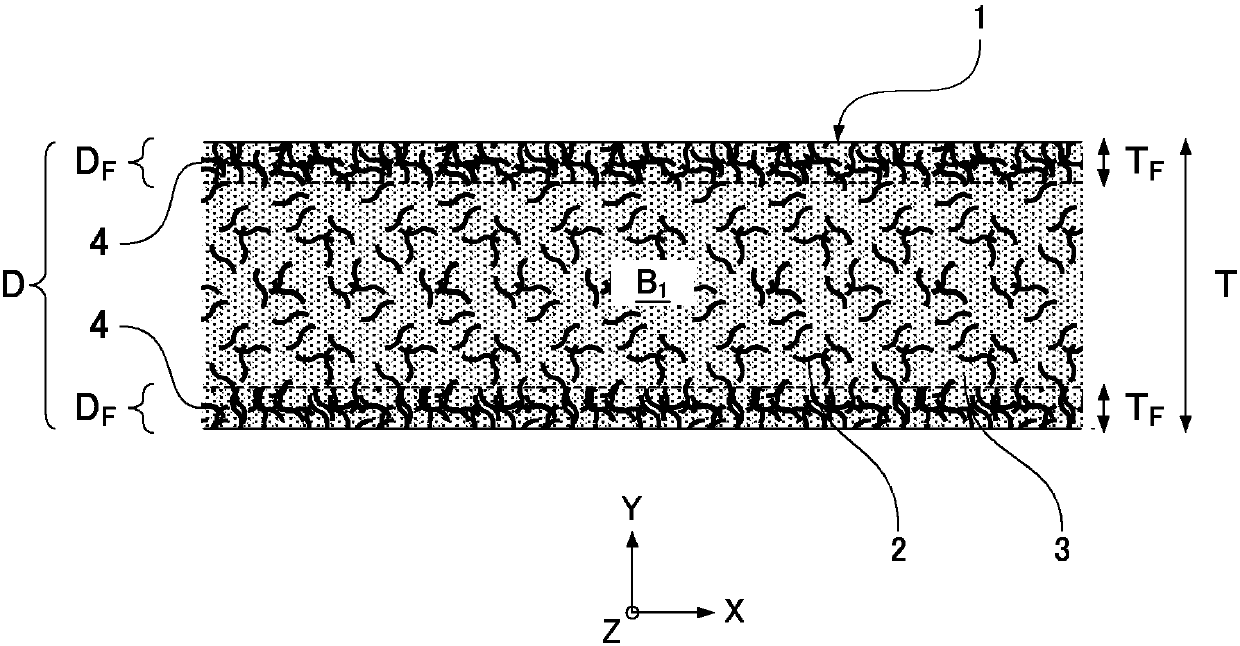

[0035] figure 1 It is a perspective view which schematically shows the molded article of Embodiment 1 of this invention. in addition, figure 2 is a cross-sectional view of a molded product 1 according to Embodiment 1 of the present invention (viewed from the direction of the arrow figure 1 A in 1 sectional drawing). image 3 is an enlarged cross-sectional view of a molded product 1 according to Embodiment 1 of the present invention ( figure 2 B in 1 zoom in). Figure 1 ~ Figure 3 In , the same symbols are used for the same components.

[0036] like figure 1 and figure 2 As shown, the molded product 1 is formed in a box shape with one side open. Additionally, if image 3 As shown, the molded article 1 is formed of a resin material 3 in which cellulose-based fibers 2 are dispersed. image 3 This is a conceptual diagram, and the size and the like of the cellulose-based fibers 2 are different from the actual reduced scale. Below, refer to image 3 The distribution ...

Embodiment approach 2

[0062] Figure 4 It is a perspective view which schematically shows the molded article 11 which concerns on Embodiment 2 of this invention. in addition, Figure 5 is a cross-sectional view of a molded product 11 according to Embodiment 2 of the present invention (viewed from the direction of the arrow Figure 4 A in 2 sectional drawing). Image 6 is an enlarged cross-sectional view of a molded product 11 according to Embodiment 2 of the present invention ( Figure 5 B in 2 zoom in). Figure 4 ~ Figure 6 in, right with Figure 1 ~ Figure 3 The same symbols are used for the same components, and detailed descriptions are omitted.

[0063] like Figure 4 and Figure 5 As shown, the molded product 11 is formed in a cylindrical shape whose cross section is closed into a ring shape. Additionally, if Image 6 As shown, the molded product 11 is formed of a resin material 3 in which cellulose-based fibers 2 are dispersed. Image 6 This is a conceptual diagram, and the size a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com