Preparation method for temperature-resistant reinforced wood-plastic composite material

A wood-plastic composite material and enhanced technology, which is applied in the field of high-performance fibers and composite materials, can solve the problems of limited improvement in the temperature resistance and stability of wood-plastic composite materials, so as to improve surface activity and specific surface area, improve stability, Improve the effect of heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

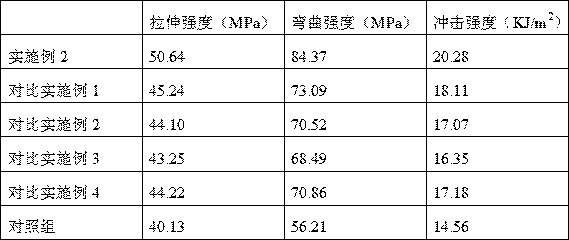

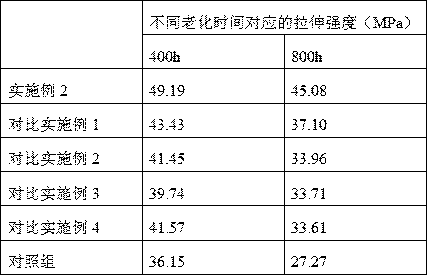

Examples

Embodiment 1

[0039] A method for preparing a temperature-resistant reinforced wood-plastic composite material, comprising the steps of:

[0040] (1) Preparation of reinforced basalt fiber:

[0041] 1) First put the mullite powder into the nitric acid solution for soaking for 3 minutes, then filter it out and put it into the tartaric acid solution for soaking treatment for 4 minutes. Finally, filter out and rinse with deionized water for later use;

[0042] 2) Put the mullite powder treated in operation 1) into the calcination furnace, first heat and keep the temperature in the calcination furnace at 360°C, heat preservation and calcination for 25 minutes, then raise the temperature in the calcination furnace to 880°C, heat preservation and calcination Take it out after 45 minutes of processing, and let it cool naturally to room temperature for later use;

[0043] 3) Put the mullite powder treated in operation 2) into the modified treatment solution, heat to keep the temperature of the mo...

Embodiment 2

[0066] A method for preparing a temperature-resistant reinforced wood-plastic composite material, comprising the steps of:

[0067] (1) Preparation of reinforced basalt fiber:

[0068] 1) Put the mullite powder into the nitric acid solution for soaking treatment for 3.5 minutes. After the treatment is completed, filter it out and put it into the tartaric acid solution for soaking treatment for 4.5 minutes. After the treatment is completed, filter it out and put it into the sodium hydroxide solution for soaking treatment for 4 minutes. After the treatment is completed, filter out and rinse with deionized water for later use;

[0069] 2) Put the mullite powder treated in operation 1) into the calcination furnace, first heat and keep the temperature in the calcination furnace at 380°C, heat-preserve and calcine for 30 minutes, then raise the temperature in the calcine to 900°C, heat-preserve and calcine Take it out after processing for 50 minutes, and let it cool naturally to ro...

Embodiment 3

[0093] A method for preparing a temperature-resistant reinforced wood-plastic composite material, comprising the steps of:

[0094] (1) Preparation of reinforced basalt fiber:

[0095] 1) Put the mullite powder into the nitric acid solution for soaking treatment for 4 minutes. After the treatment is completed, filter it out and put it into the tartaric acid solution for soaking treatment for 5 minutes. After the treatment is completed, filter it out and put it into the sodium hydroxide solution for soaking treatment for 5 minutes. The treatment is completed Finally, filter out and rinse with deionized water for later use;

[0096] 2) Put the mullite powder treated in operation 1) into the calcination furnace, first heat and keep the temperature in the calcination furnace at 420°C, heat-preserve and calcine for 35 minutes, then raise the temperature in the calcine to 950°C, heat-preserve and calcine Take it out after 55 minutes of processing, and let it cool naturally to room ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com