Molded article

A molded product, polyolefin resin technology, applied in the field of molded products in the resin department, can solve the problems of large cellulose aggregates, difficult resin compounds, lack of affinity for cellulose, etc., and achieve excellent recyclability and high-strength dimensions Excellent precision and acoustic characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0134] A polyolefin resin composite material was prepared through the following steps.

[0135] 1) Preparation steps of polyolefin resin composite material

[0136] In the twin-screw extruder [KZW15TW-45MG-NH (trade name) manufactured by Technobel Corporation], the polyolefin resin was dropped into at an outlet temperature of 190° C. at a rate of 1000 g / hour, and passed through the second feeder at a rate of 110 g / hour. Add cellulose A at a speed of 200°C, add water at a rate of 98 g / hour using a liquid feeding pump, melt and knead the mixture satisfying the composition of Table 1 below at 200° C., and then extrude to prepare a polyolefin resin composite material. The screw speed was set at 100 rpm.

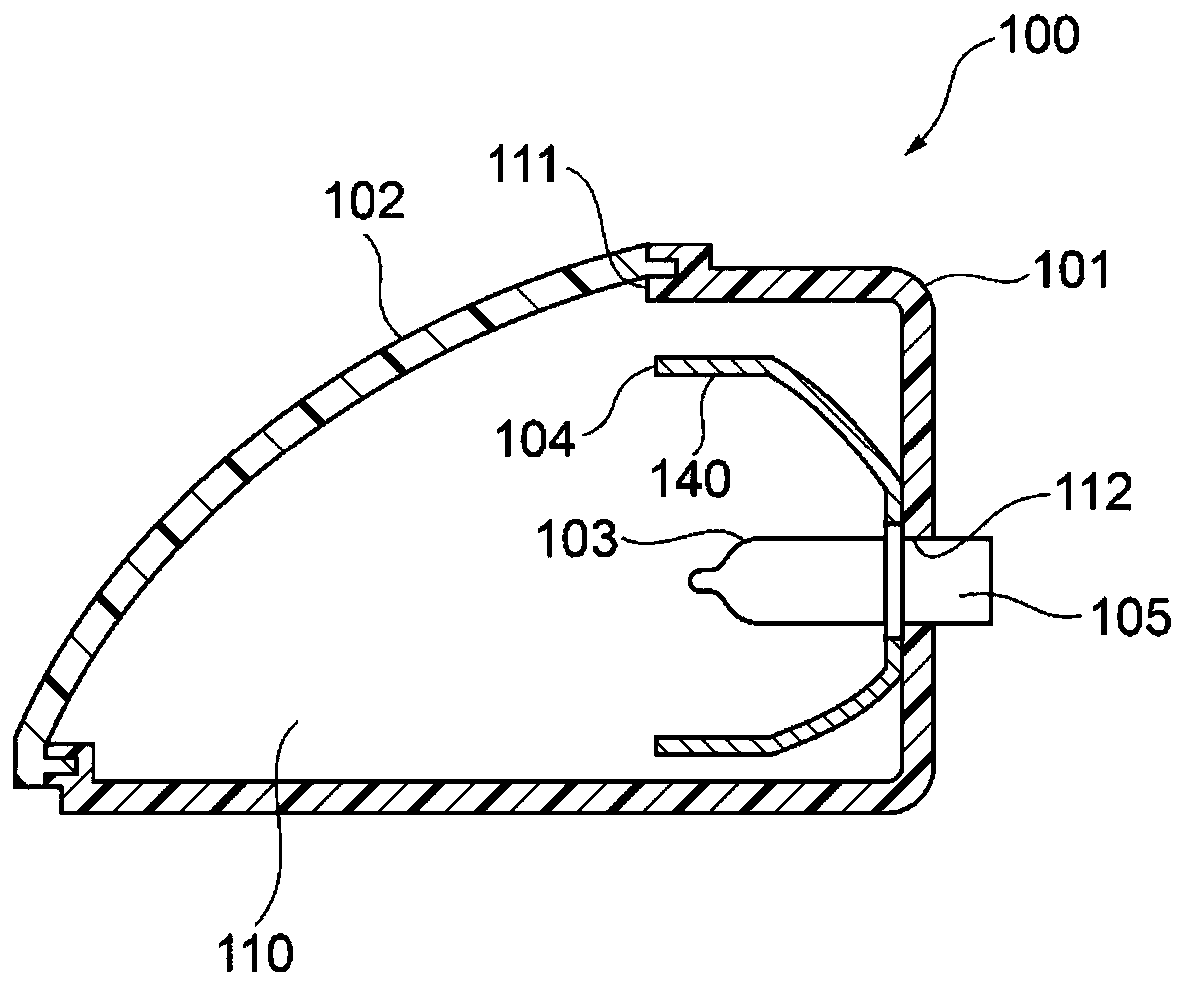

[0137] 2) Manufacturing steps of lamp body

[0138] The polyolefin resin composite material prepared in the above 1) was used for injection molding to produce a lamp body including a resin portion. In addition, the injection conditions are carried out under appropriate molding...

Embodiment 2~14、 comparative example 1~3

[0140] Except having adopted the composition of following Table 1, it carried out similarly to Example 1, and the polyolefin resin composite material of Examples 2-14 and Comparative Examples 1-3 was produced. Next, using this polyolefin resin composite material, a lamp body including a resin portion was prepared in the same manner as in Example 1. In addition, in Comparative Example 3, the mixing amount of water was too large, and the discharge amount of the extruder became unstable.

Embodiment 15

[0142] The steps of 1) in Example 1 were also carried out to prepare polyolefin resin composite materials.

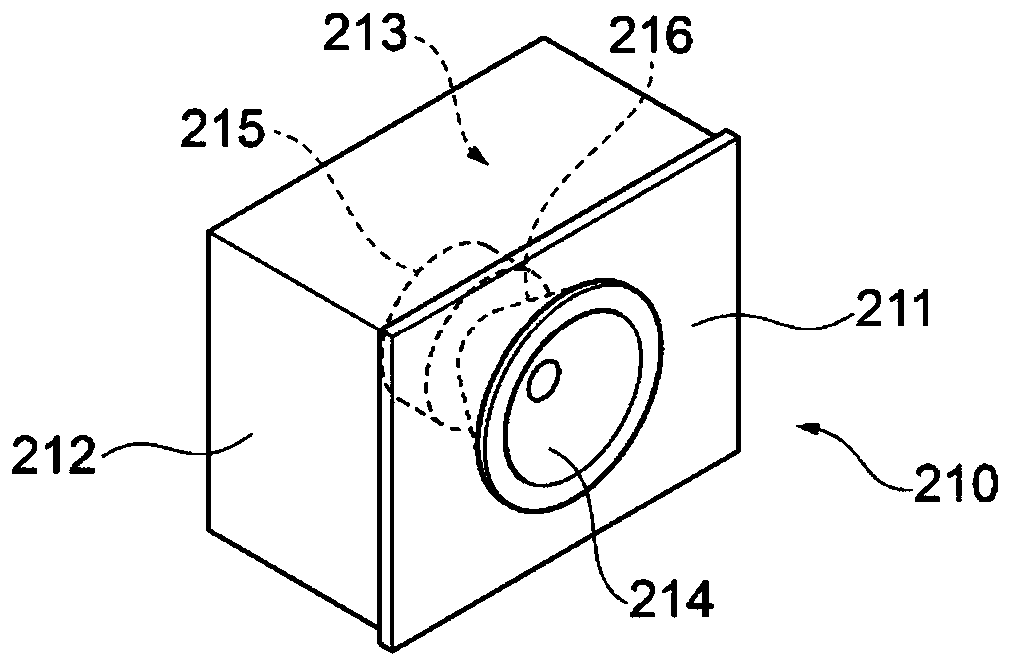

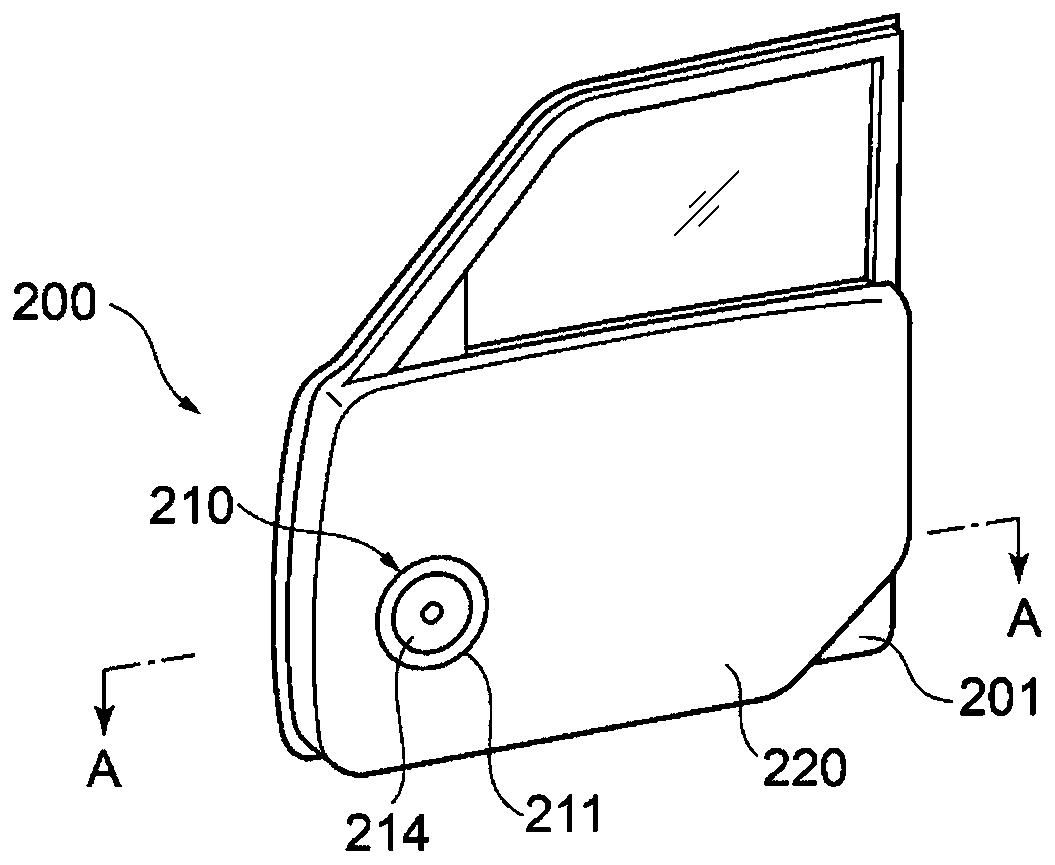

[0143] 3) Manufacturing steps of the speaker assembly

[0144] The polyolefin resin composite material prepared by the method described above was injection molded to produce a speaker assembly including a resin part. In addition, the injection conditions were carried out under appropriate molding conditions commonly used in injection molding of speaker components.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com