A Mixing Nozzle with Surface Shot Peening Strengthening

A technology of mixing nozzles and shot peening, which is applied in the field of surface strengthening, can solve the problems that the surface quality of shot peening materials cannot be guaranteed, the surface accuracy of parts is reduced, and the amount of shot peening is large, so as to shorten the processing time, improve surface performance, The effect of dust pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

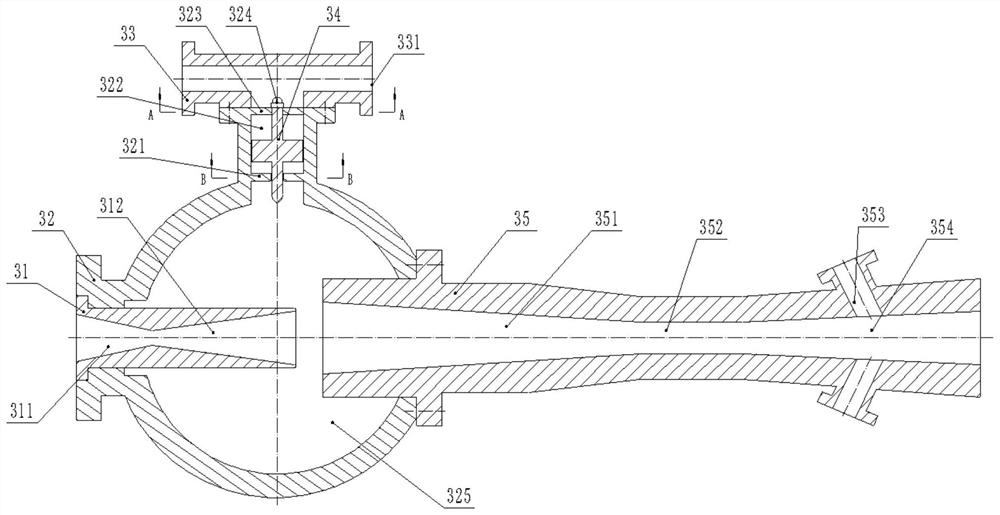

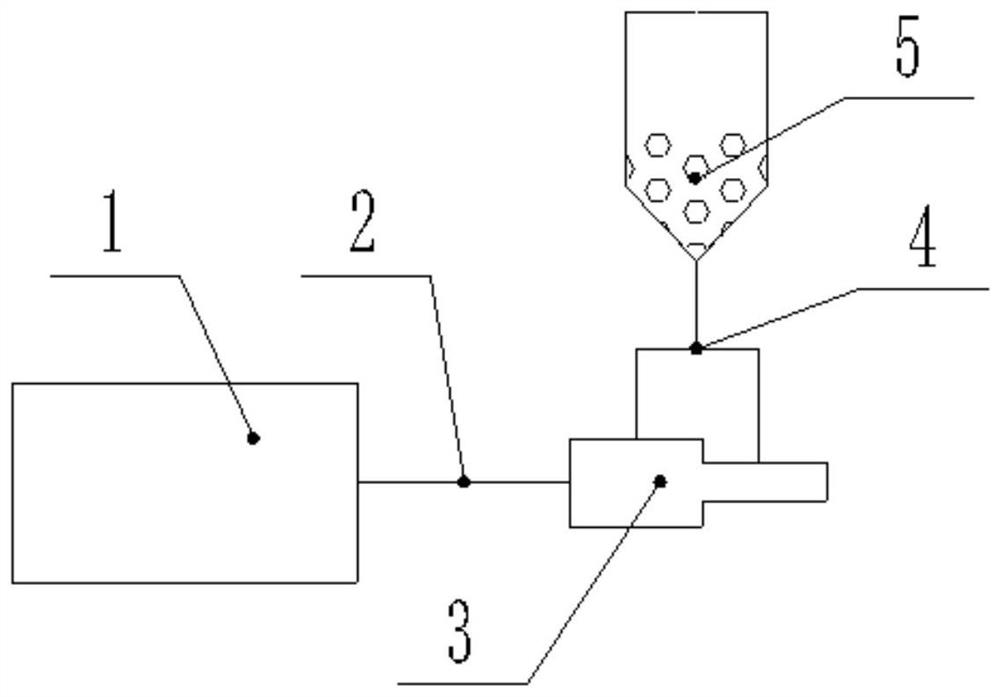

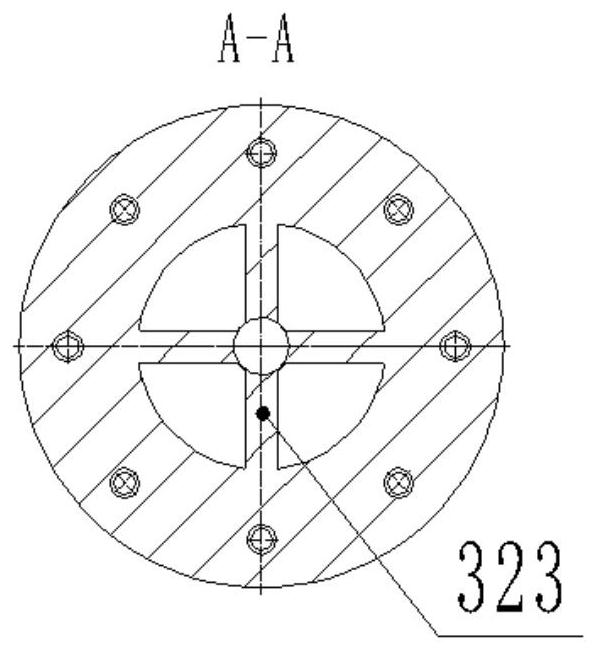

[0026] Such as figure 1 As shown, the mixing nozzle 3 for surface shot-peening strengthening of the present invention includes a liquid nozzle 31 and a shot-peening nozzle 35, and the liquid nozzle 31 is installed on the shell 32 for inputting high-pressure liquid into the inside of the shell 32, That is, the mixing nozzle inner cavity 325, the liquid nozzle 31 goes deep into the mixing nozzle inner cavity 325; the shell 32 is provided with a first shot feed section 33, which is used to make the shot blasting input into the shell 32; Pill nozzle 35 is installed on the shell 32, is used for outputting the solid-liquid mixture of shot blasting and liquid; Mix with the solid-liquid mixture. The inside of the liquid nozzle 31 is provided with a contraction section 311 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com