Thermal resistance test circuit and method of reverse conduction type igbt

A test circuit, reverse conduction type technology, applied in the direction of single semiconductor device testing, measuring electricity, measuring electrical variables, etc., can solve the problem of low accuracy of thermal resistance testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

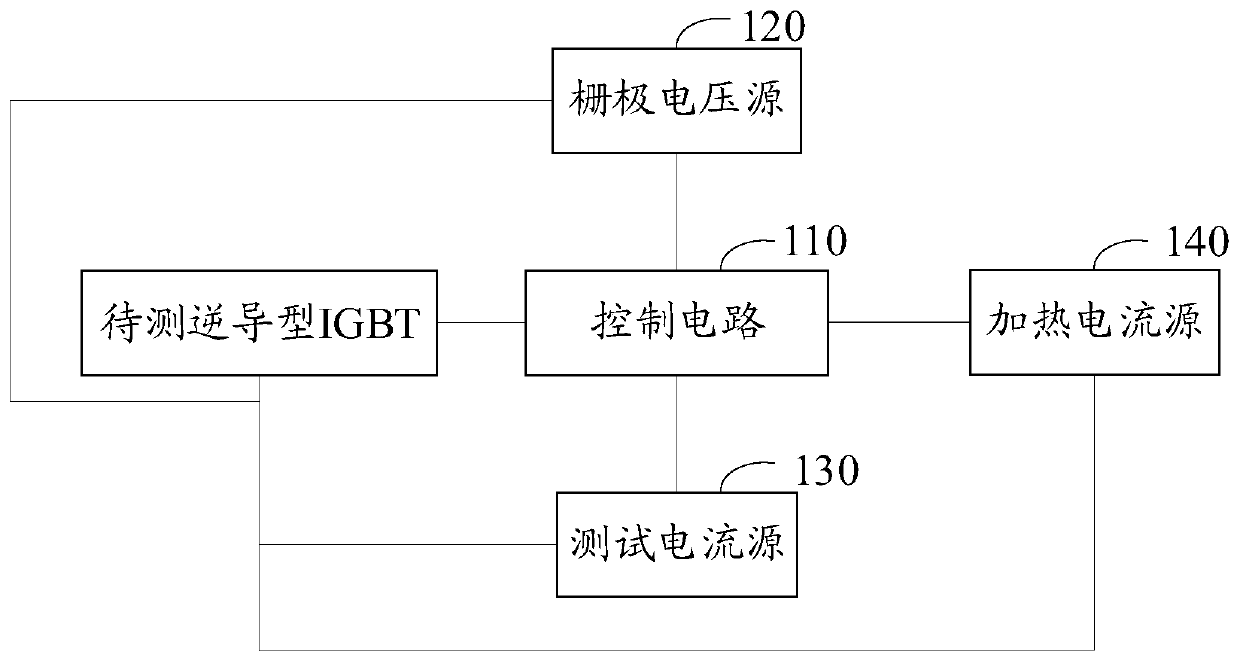

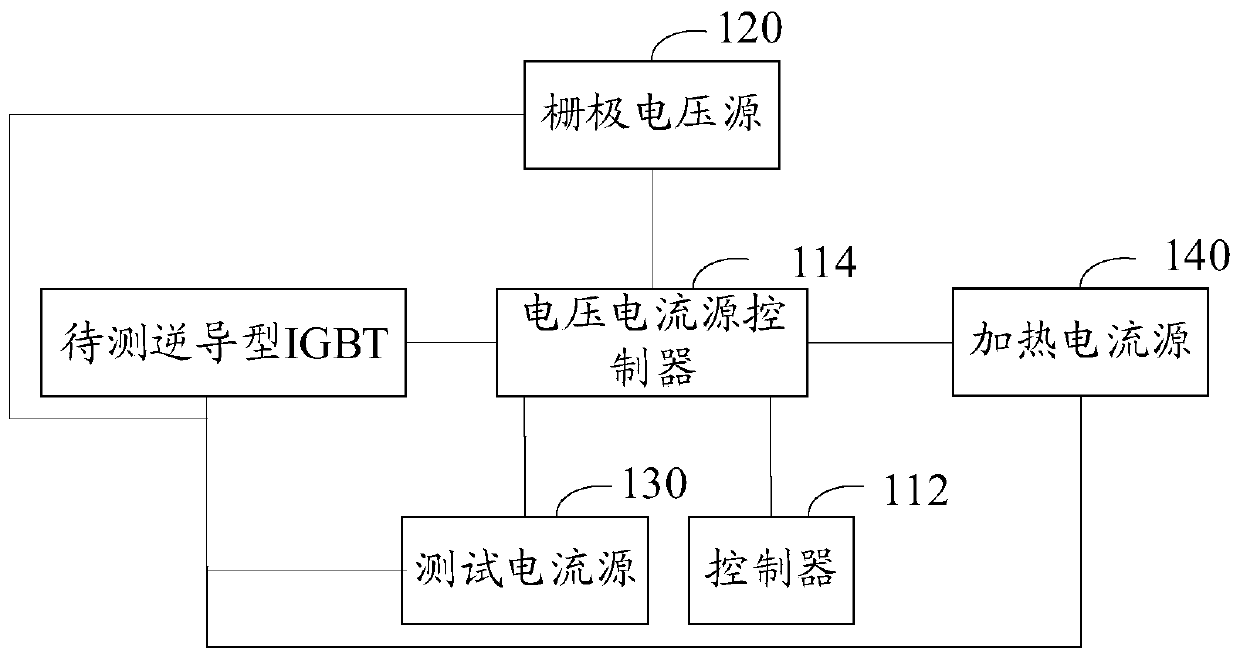

[0020] In one embodiment, such as figure 1 As shown, a thermal resistance test circuit of a reverse conduction type IGBT includes a control circuit 110, a gate voltage source 120, a test current source 130 and a heating current source 140, and the gate voltage source 120, a test current source 130 and a heating current source 140 are all connected to the control circuit 110, the gate voltage source 120, the test current source 130, the heating current source 140 and the control circuit 110 are all used to connect the reverse conduction IGBT to be tested, wherein the reverse conduction IGBT to be tested includes a gate, a collector electrode and emitter, the control circuit 110 controls the test current source 130 to output a reverse test current to the reverse conduction type IGBT to be tested to obtain a preset reverse test current condition, the voltage drop between the collector and the emitter of the reverse conduction type IGBT to be tested With the curve of the junction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com