A double-inlet and double-outlet ball mill control system and control method based on rbf neural network predictive control

A double-input, double-out, neural network technology, applied in grain processing, etc., can solve problems such as failure to achieve results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

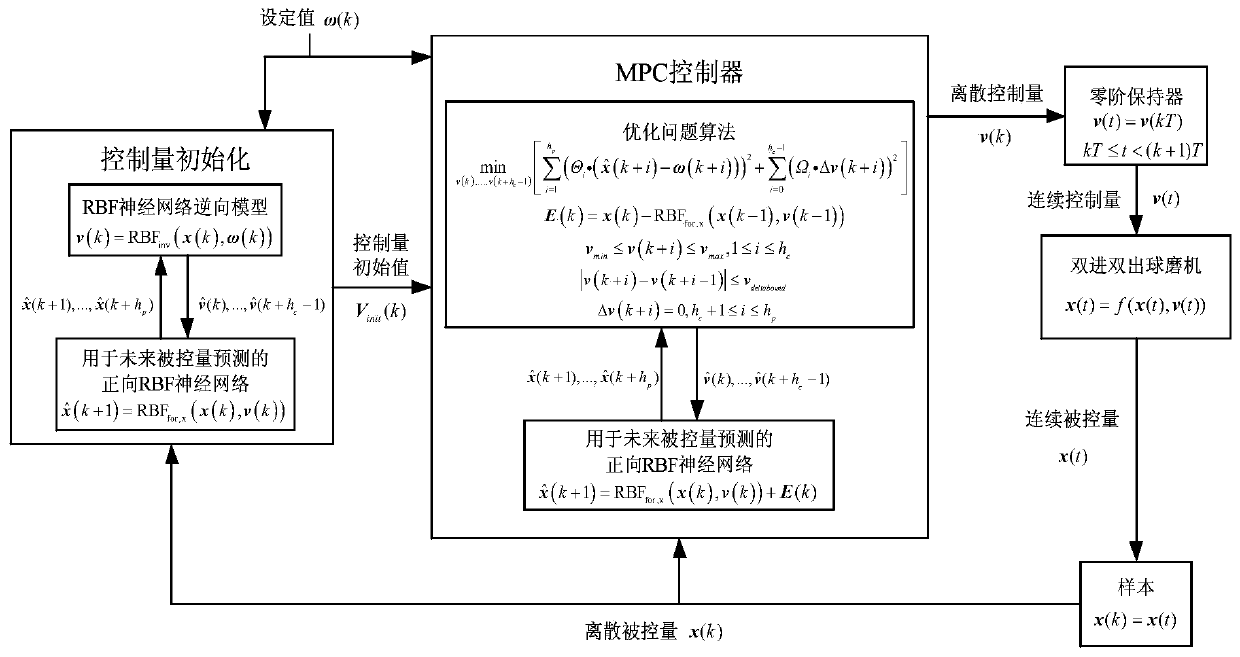

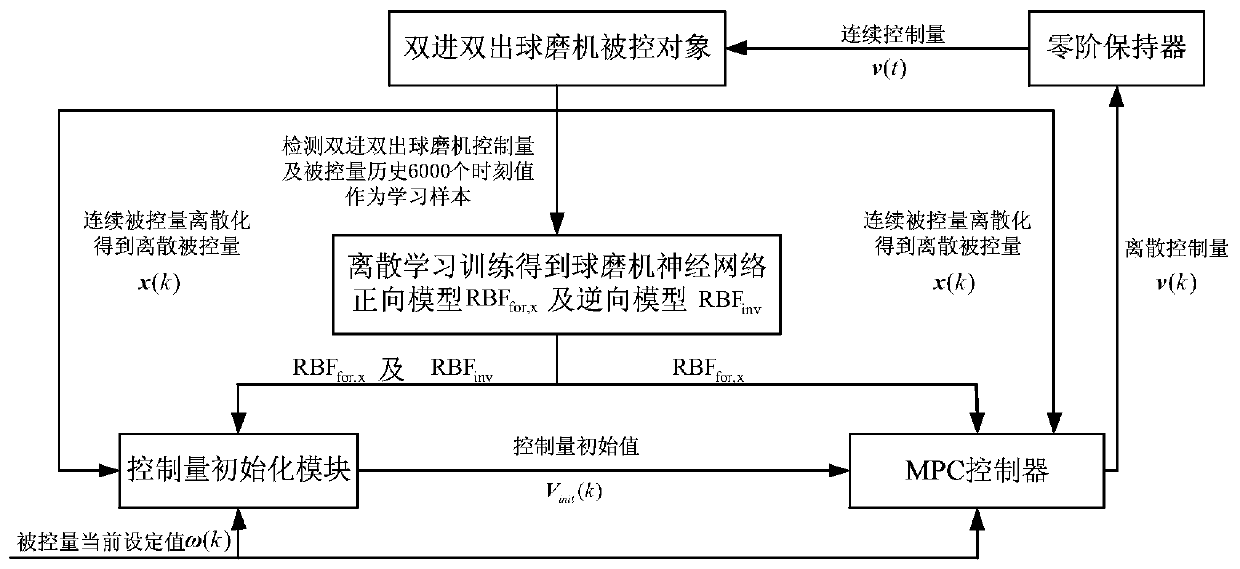

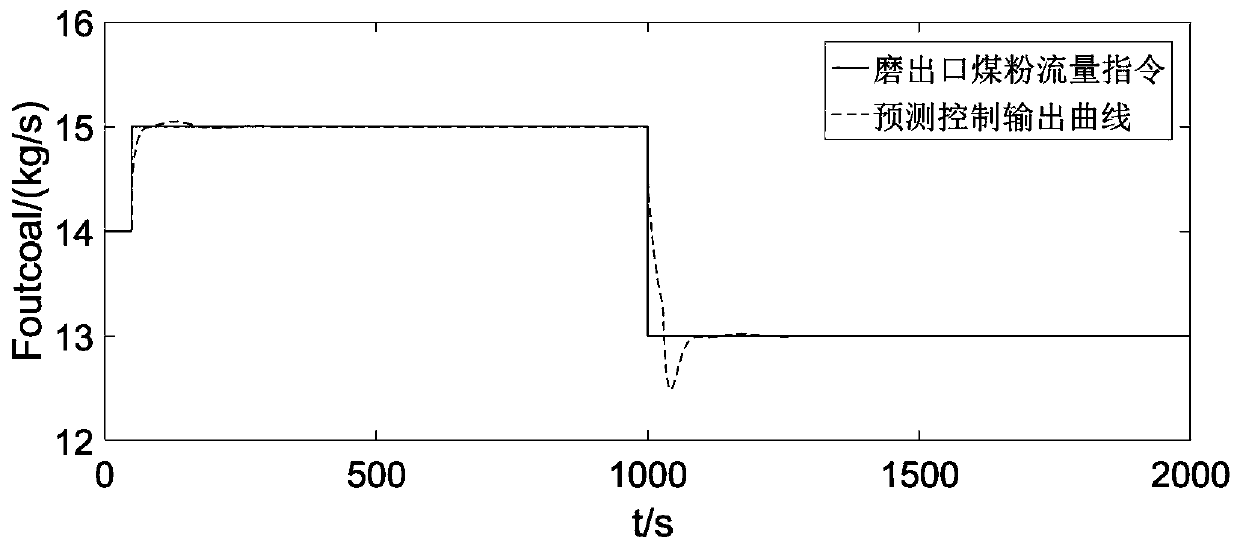

[0069] Such as figure 1 Shown is a schematic diagram of a double-input double-outlet ball mill control system based on RBF neural network predictive control. The predictive controller (MPC controller) is used as the controller of the feedback loop, and the RBF neural network method is used for control in the control quantity initialization loop. Quantity initial value calculation. The predictive control technology can ensure the stability and safety of the controlled system, and improve the speed of adjustment of the double-inlet and double-outlet ball mill pulverization system, so that the pulverization output can track the command changes well, and in the pulverization output adjustment process In the process, the stability of the system is maintained, and the speed and accuracy of system adjustment are improved....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com