A kind of double-layer elbow processing method

A double-layer elbow and processing method technology, applied in the field of elbow processing, can solve problems such as difficult production of elbows, inability to set elbows, and difficult production process, so as to reduce production costs, increase heat exchange rate, and improve The effect of energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

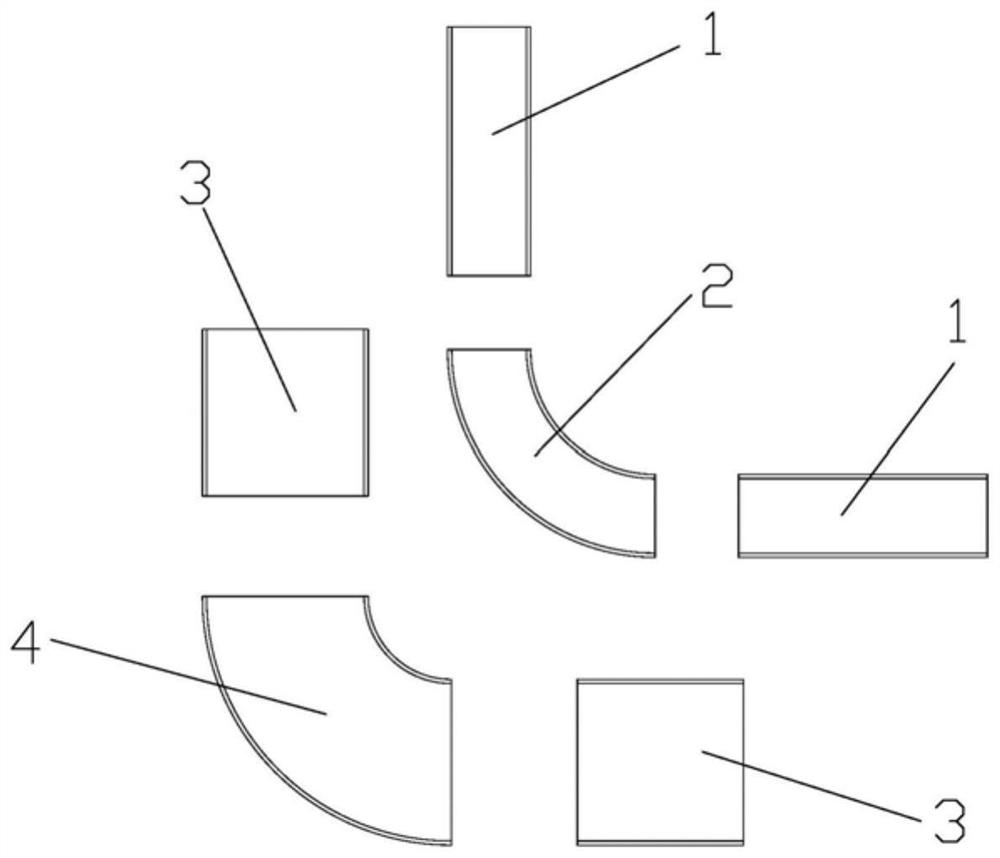

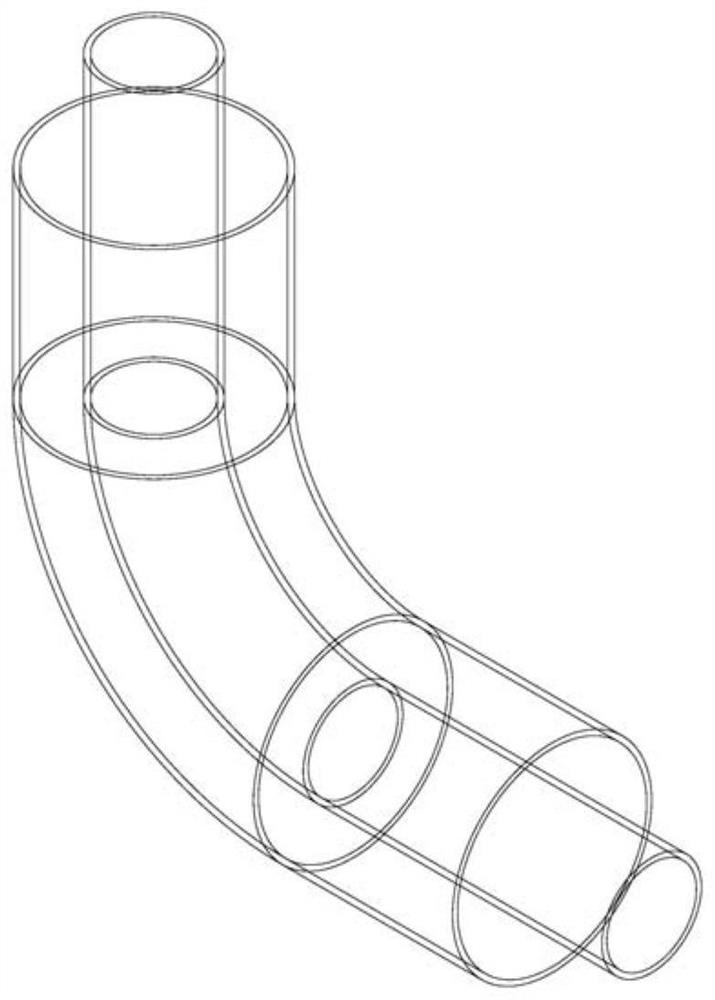

[0029] like Figure 1-2 As shown, this embodiment provides a double-layer elbow processing method, when the required double-layer elbow is a 90-degree elbow, the following steps are included:

[0030] Material preparation: prepare a 90-degree inner elbow 2, a 90-degree outer elbow 4, two inner straight pipes 1 and two outer straight pipe 3;

[0031] Welding: Weld one inner straight pipe 1 at one end of the inner elbow 2, set the outer elbow 4 on the inner elbow 2 and make the other end of the inner elbow 2 lie on the outer elbow 4. Externally, one inner straight pipe 1 is welded at the other end of the inner curved pipe 2, and one outer straight pipe 3 is respectively welded at both ends of the outer curved pipe 4.

[0032] The length of the inner straight pipe 1 is greater than the length of the outer straight pipe 3 .

[0033] Due to the long length of the pipeline, when the temperature changes, the thermal expansion and contraction on the pipeline will be concentrated at...

Embodiment 2

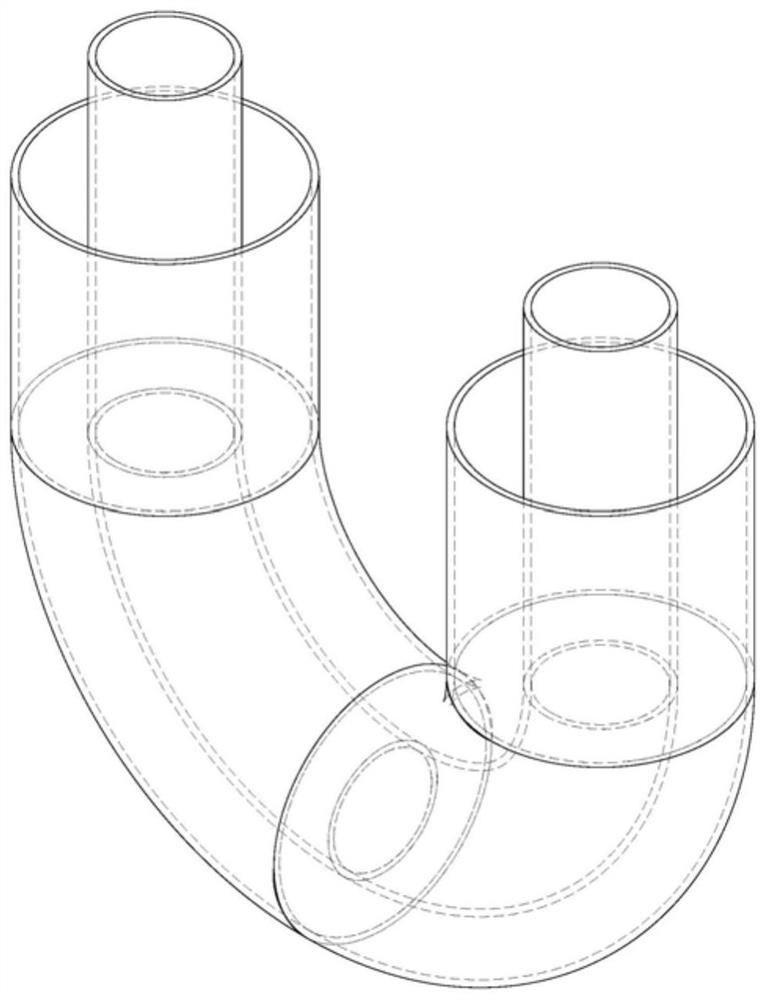

[0035] like image 3 As shown, this embodiment provides a double-layer elbow processing method, when the required double-layer elbow is a 180-degree elbow, the following steps are included:

[0036] Material preparation: Prepare two 90-degree inner bends 2, two 90-degree outer bends 4, two inner straight pipes 1 and two 3 outer straight pipes;

[0037] Welding: one inner straight pipe 1 is welded at one end of each inner curved pipe 2, and one outer curved pipe 4 is sleeved on the inner curved pipe 2 welded with an inner straight pipe 1 at each end And the other end of the inner elbow 2 is located outside the outer elbow 4, the other ends of the two inner elbows 2 are welded together, and the adjacent ends of the two outer elbows 4 are welded on Together, one outer straight pipe 3 is respectively welded at the other end of each outer curved pipe 4 .

[0038] The length of the inner straight pipe 1 is greater than the length of the outer straight pipe 3, so as to facilitate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com