Electric drill support for upward position drilling for cantilever slab, and use method thereof

A cantilever plate, electric drill technology, applied in stone processing tools, work accessories, manufacturing tools and other directions, can solve the problems of inconvenient operation, low construction efficiency, unsafe, etc., to improve work efficiency and safety, reduce work intensity , The effect of convenient air-conditioning control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

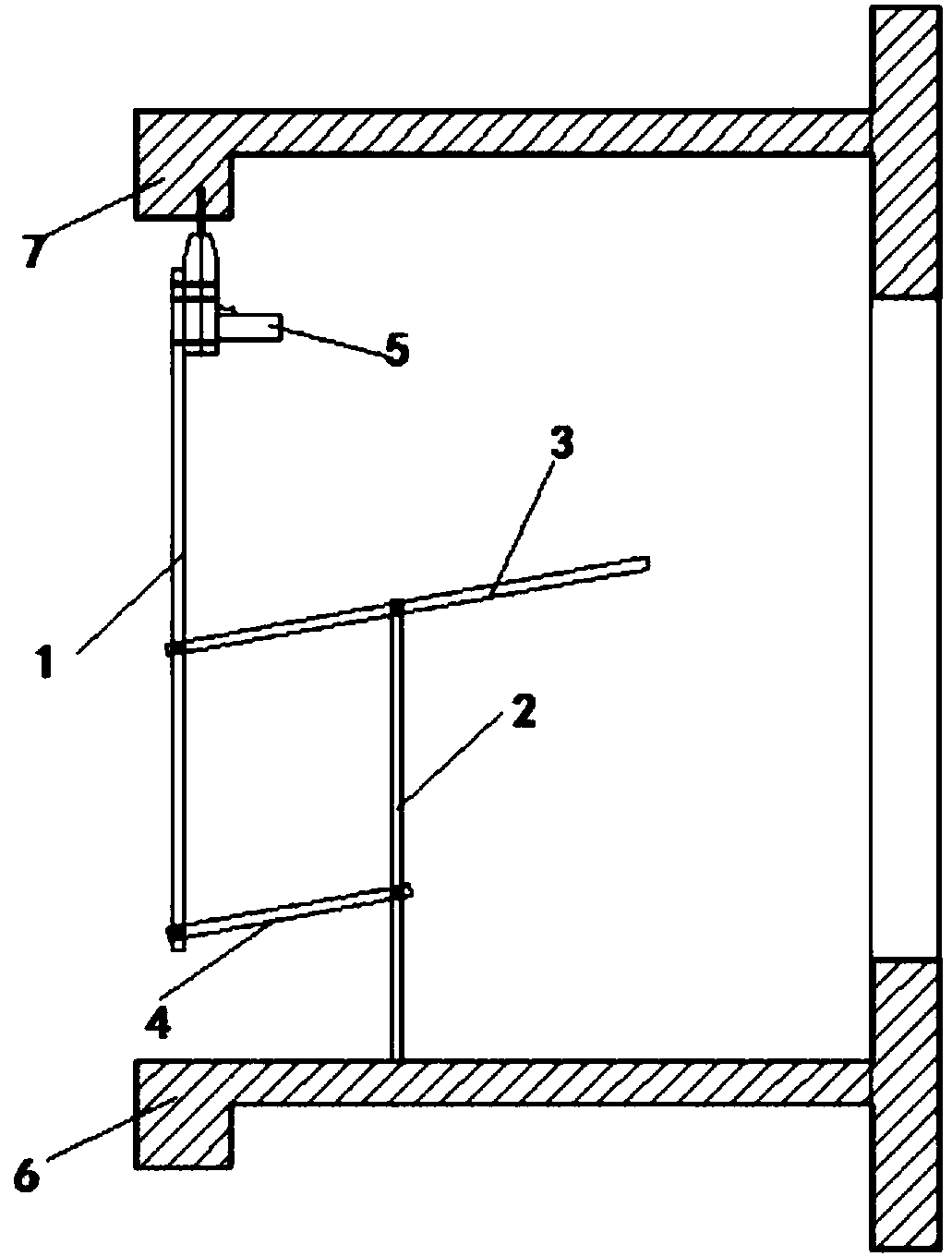

[0024] An electric drill bracket for drilling upwards at the position of the cantilevered plate, such as figure 1 As shown, it includes two opposite upper vertical rods 1 and lower vertical rods 2, and the upper vertical rod 1 and the lower vertical rod 2 are connected from top to bottom through the pressure rod 3 and the connecting rod 4; at the same time, the upper vertical rod 1 Set in parallel with the lower vertical rod 2, the pressure rod 3 and the connecting rod 4 are also arranged in parallel, and form a parallelogram between the upper vertical rod 1, the lower vertical rod 2, the pressure rod 3 and the connecting rod 4; and the lower vertical rod 2 The bottom end is in contact with the surface of the lower cantilever plate 6, and the lower vertical rod 2 is supported on the surface of the lower cantilever plate 6 during use;

[0025] One end of the connecting rod 4 is hingedly fixed to the bottom end of the upper vertical rod 1, and the other end is hingedly fixed to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com