Side car production technology for three-wheeled motorcycle with side car

A technology of three-wheeled motorcycles and production technology, which is applied to sidecars, bicycle accessories, transportation and packaging, etc. It can solve the problems of limited riding space, increased body weight, and low safety, and achieves smaller and lower driving wind resistance. Effects of improving fuel consumption and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

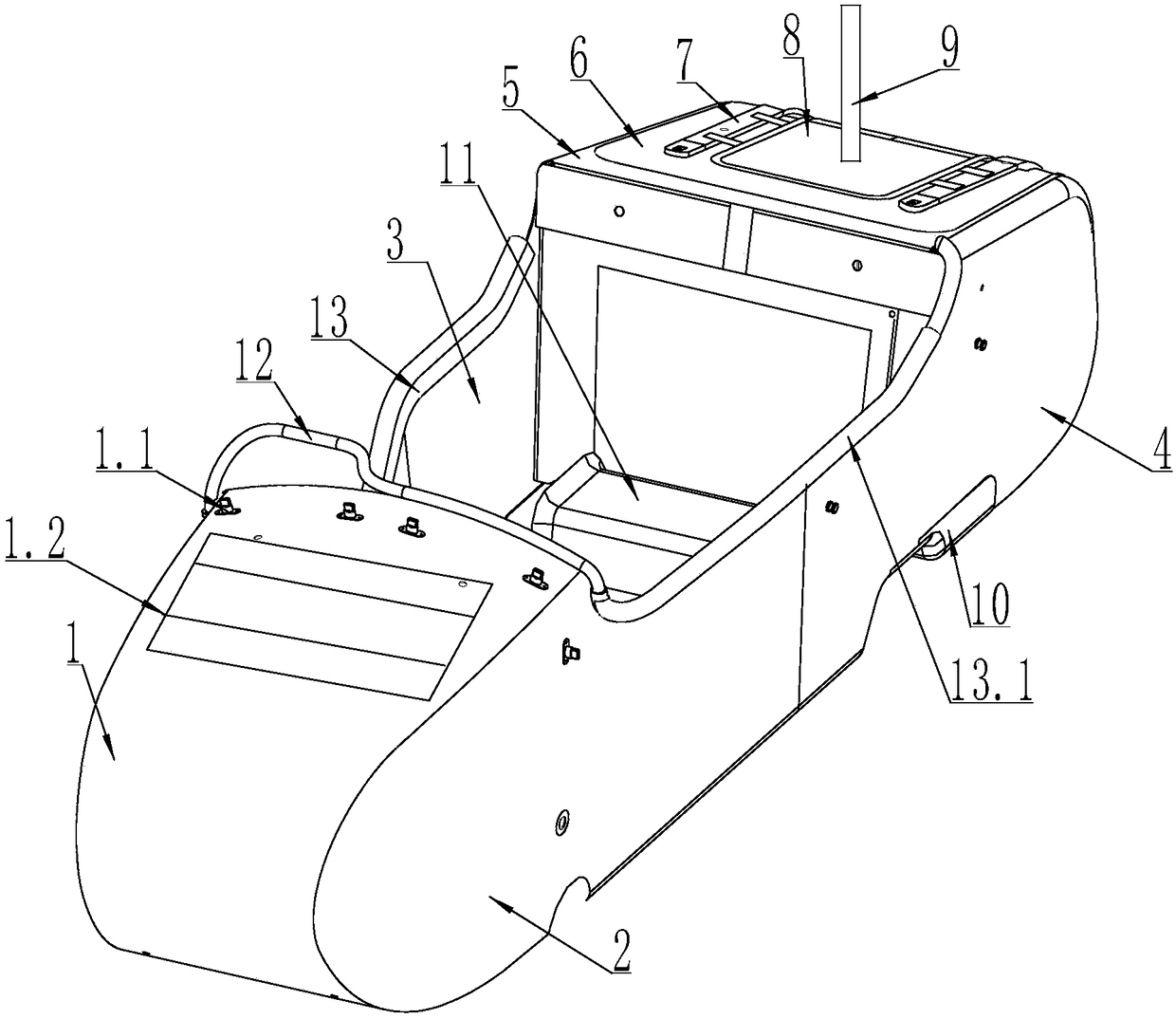

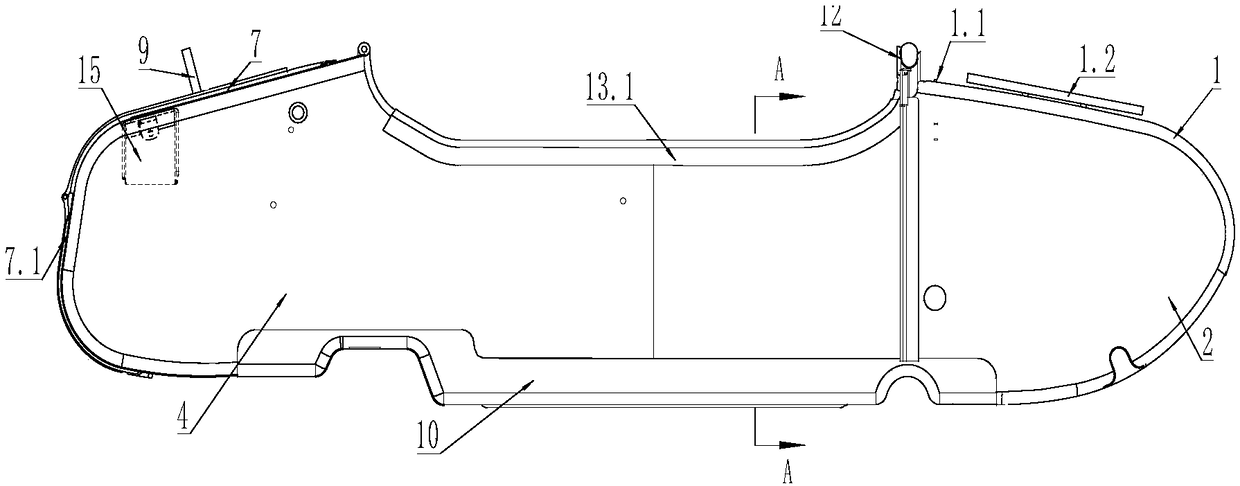

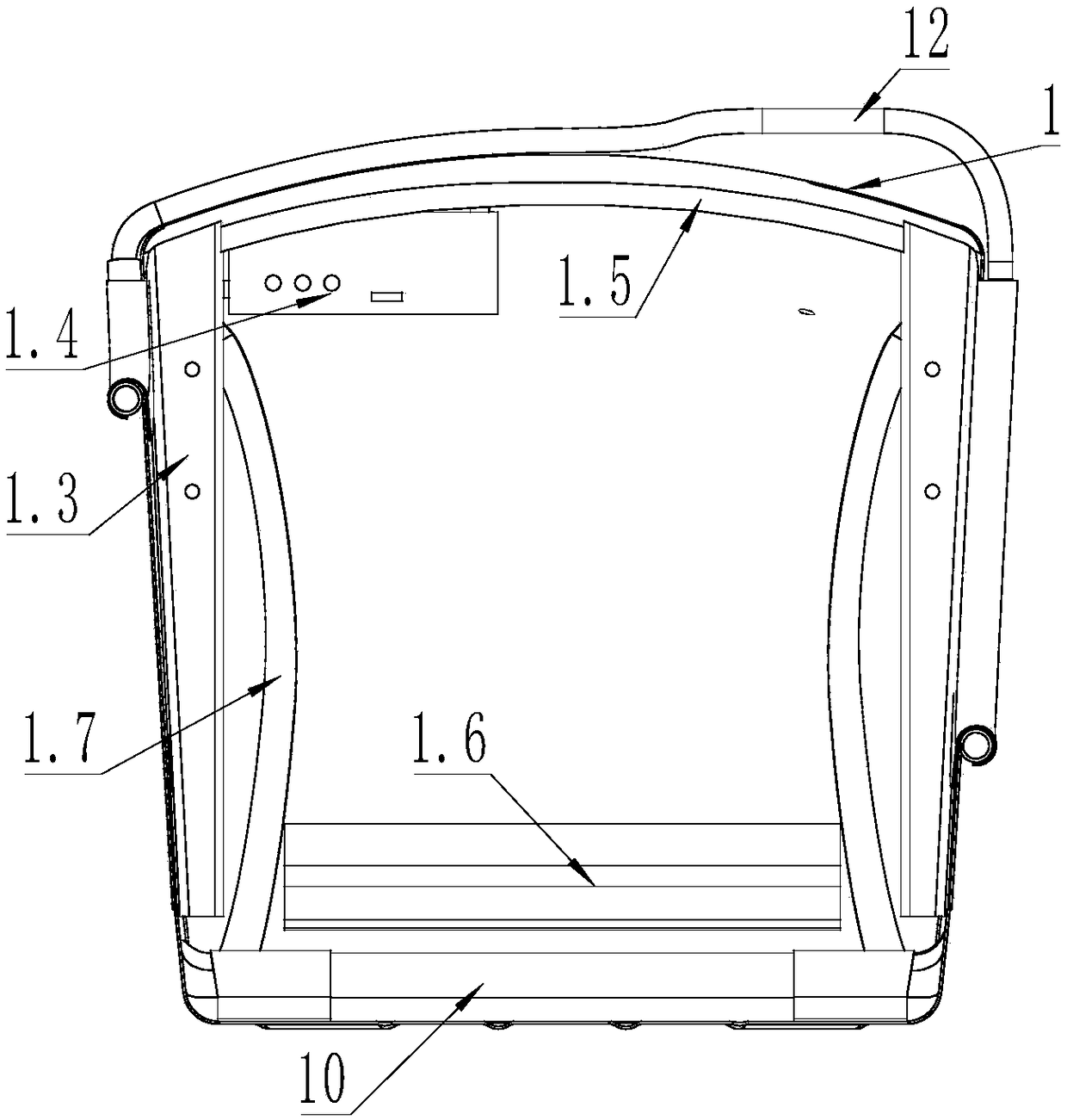

[0044] The side view structure of the front cover 1 is C-shaped, the middle part of the upper curved surface of the front cover 1 is provided with a placement frame 1.2, and the placement frame 1.2 is connected with the front cover 1 by bolts, and the C-shaped opening of the front cover 1 Handrails 12 are arranged on the upper surface of the end, and the side view structure of the rear cover 5 is C-shaped. A bottom box plate 10 is arranged between the lower end of the C-shaped opening of the front cover 1 and the lower end of the C-shaped opening of the rear cover 5, and the front cover A pair of front upright pillars 1.3 are arranged symmetrically between both sides of the upper end surface of the board 1 and both sides of the upper surface of the bottom box board 10, and the front left box board 2 and the front right box board 3 are respectively symmetrically arranged on both sides of the front cover board 1. The front left box panel 2, the front right box panel 3 and the bot...

Embodiment 2

[0049] The first step, stamping: press the Q235 steel plate on the punching machine according to the specified size and specifications to form the front cover 1, the front left box panel 2, the front right box panel 3, the rear side box panel 4, the rear cover panel 5, and the bottom box Plate 10, handrail 12, remove the burrs and flashes of the formed front cover 1, front left box panel 2, front right box panel 3, rear side box panel 4, rear cover panel 5, bottom box panel 10, and handrail 12 ;

[0050] The second step, welding: first, the front side bucket is welded and formed. The front side bucket is composed of a C-shaped front cover plate 1, a front left box panel 2 and a front right box panel 3. Carry out spot welding and positioning at the connection between the cover plate 1 and the front left box panel 2 on one side of the front cover plate 1, and then use secondary welding to connect the front cover plate 1 and the front right box panel 3 on the other side of the fr...

Embodiment 3

[0070] Described front right box board 3 is provided with inlet and outlet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com