Winding and packing device for pipes

A technology for pipes and wrapping tapes is applied in the field of wrapping and packaging devices for pipes, which can solve the problems of damage to the anti-corrosion protective layer, insufficient work efficiency, damage, etc., and achieve the effects of reducing production costs, high processing efficiency, and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

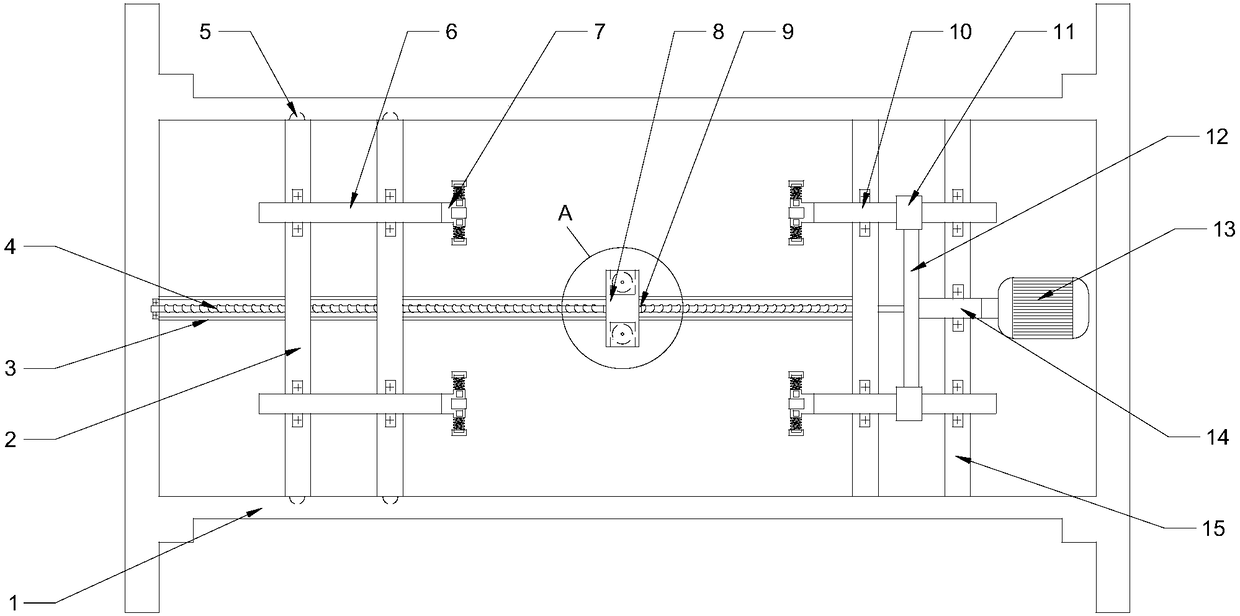

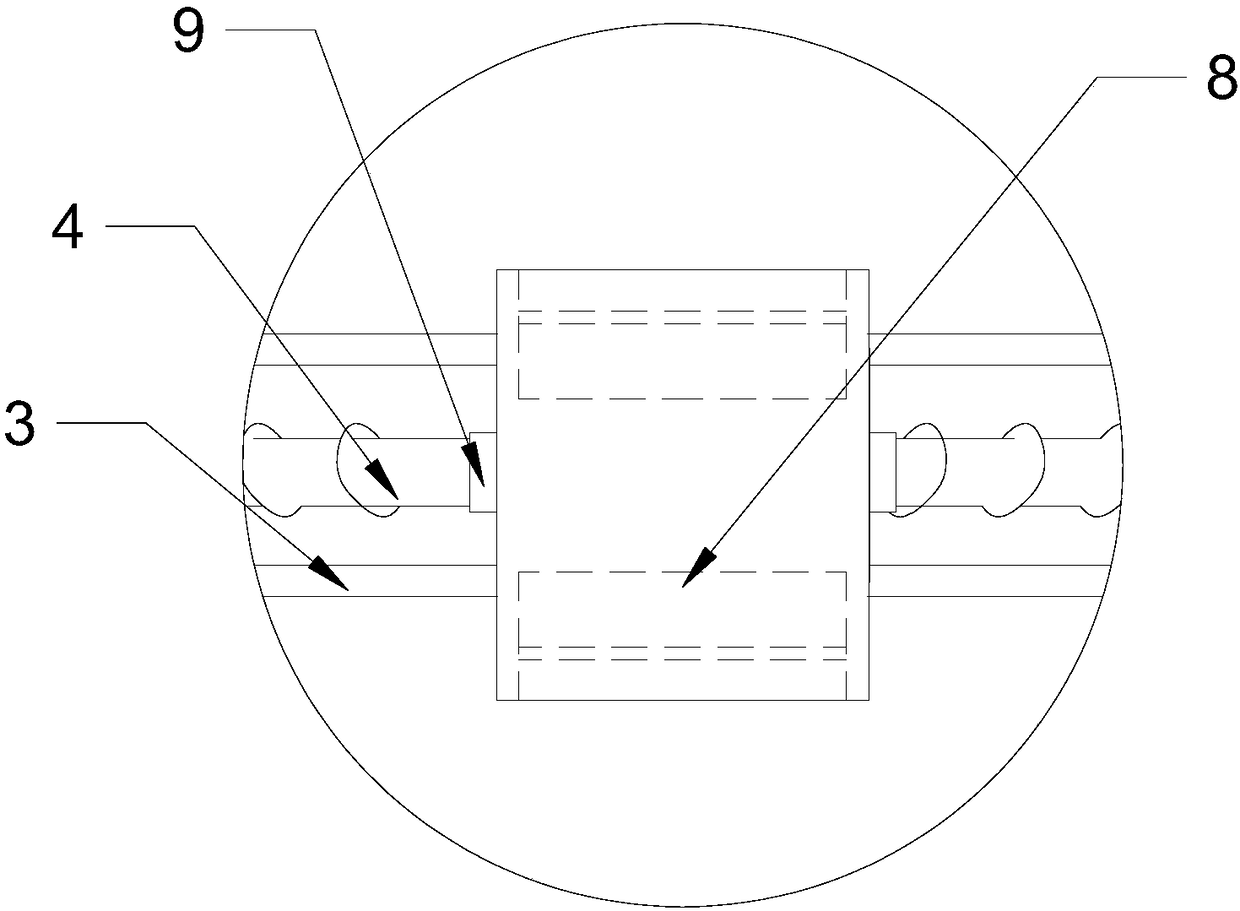

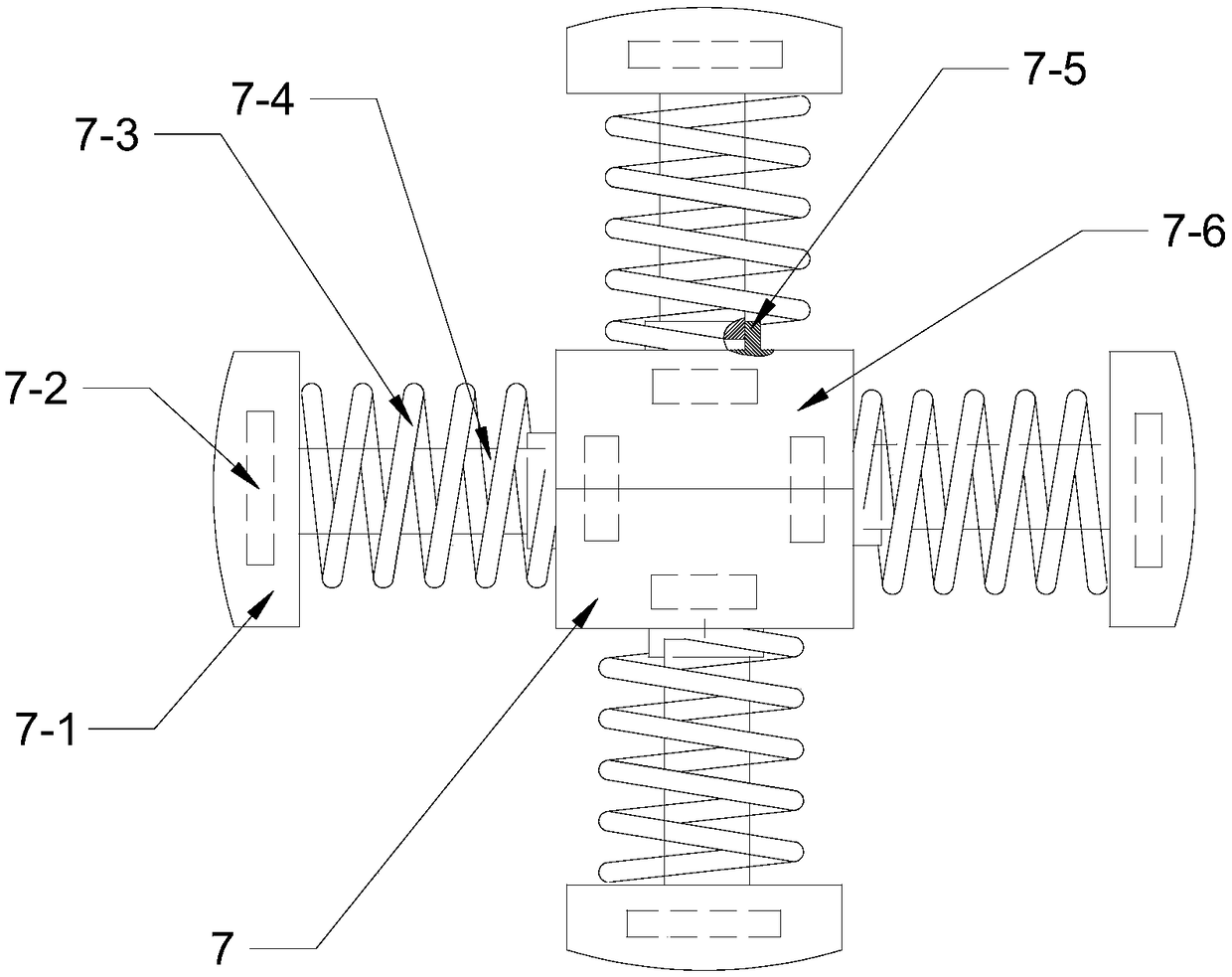

[0027] See Figure 1~4 , A winding and packing device for pipes, including a bracket 1. The bracket 1 is a square frame. The two sides of the square frame are provided with a sliding frame 2 and a fixing frame 15. The sliding frame 2 is provided with a roller 5, and the bracket 1 is There is a roller groove, the roller 5 on the sliding frame 2 is embedded in the roller groove on the bracket 1, and the fixed frame 15 is provided with a driving gear 12 and a plurality of driven gears 11 meshing with the driving gear 12. The driven gear 11 A driven shaft 10 passes through, the driven shaft 10 passes through the fixed frame 15 and is connected to a pipe clamping device 7, a mobile end shaft 6 is installed on the sliding frame 2, and the mobile end shaft 6 passes through the sliding frame 2 to be connected to a pipe clamping device Device 7, the pipe clamping device 7 includes a fixed head 7-6. The fixed head 7-6 is a polygonal cube. The sides of the polygonal cube are provided with...

Embodiment 2

[0030] See Figure 1~4 , A winding and packing device for pipes, including a bracket 1. The bracket 1 is a square frame. The two sides of the square frame are provided with a sliding frame 2 and a fixing frame 15. The sliding frame 2 is provided with a roller 5, and the bracket 1 is There is a roller groove, the roller 5 on the sliding frame 2 is embedded in the roller groove on the bracket 1, and the fixed frame 15 is provided with a driving gear 12 and a plurality of driven gears 11 meshing with the driving gear 12. The driven gear 11 A driven shaft 10 passes through, the driven shaft 10 passes through the fixed frame 15 and is connected to a pipe clamping device 7, a mobile end shaft 6 is installed on the sliding frame 2, and the mobile end shaft 6 passes through the sliding frame 2 to be connected to a pipe clamping device Device 7, the pipe clamping device 7 includes a fixed head 7-6. The fixed head 7-6 is a polygonal cube. The sides of the polygonal cube are provided with...

Embodiment 3

[0034] See Figure 1~4 , A winding and packing device for pipes, including a bracket 1. The bracket 1 is a square frame. The two sides of the square frame are provided with a sliding frame 2 and a fixing frame 15. The sliding frame 2 is provided with a roller 5, and the bracket 1 is There is a roller groove, the roller 5 on the sliding frame 2 is embedded in the roller groove on the bracket 1, and the fixed frame 15 is provided with a driving gear 12 and a plurality of driven gears 11 meshing with the driving gear 12. The driven gear 11 A driven shaft 10 passes through, the driven shaft 10 passes through the fixed frame 15 and is connected to a pipe clamping device 7, a mobile end shaft 6 is installed on the sliding frame 2, and the mobile end shaft 6 passes through the sliding frame 2 to be connected to a pipe clamping device Device 7, the pipe clamping device 7 includes a fixed head 7-6. The fixed head 7-6 is a polygonal cube. The sides of the polygonal cube are provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com