A kind of tire carcass steel wire rubber compound and preparation method thereof

A technology for steel wire rubber and tires, which is applied in the field of tire manufacturing, can solve the problems of poor rubber aging performance and deterioration of rubber aging performance, and achieve the effect of easy steps and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

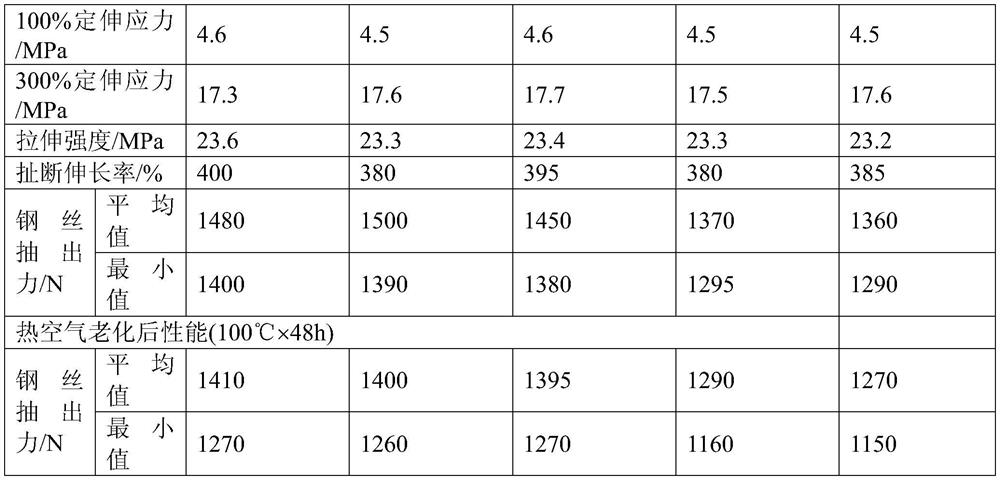

Examples

Embodiment 1

[0019] A preparation method for a tire carcass steel wire compound, comprising the steps of:

[0020] (1) One-stage master batching: add 100 parts of natural rubber, 0.1 part of B-type peptizer, 35 parts of carbon black, 6 parts of zinc oxide, 2 parts of stearic acid, 2 parts of anti-aging agent, m-benzene 1 part of diphenol, the rotor speed of the internal mixer is 45 rpm, the pressure of the top bolt is 0.5MPa, the mixing time is 50 seconds, and the glue discharge temperature is 150°C to obtain a section of masterbatch;

[0021] (2) Second-stage master batching: add one-stage masterbatch and 10 parts of carbon black to the internal mixer, the rotor speed of the internal mixer is 50 rpm, the pressure of the top bolt is 0.4MPa, the mixing time is 100 seconds, and the discharge time is 100 seconds. The glue temperature is 155°C, and the second-stage masterbatch is obtained;

[0022] (3) Final refining: add 5 parts of second-stage masterbatch, binder, 4 parts of insoluble sulfu...

Embodiment 2

[0024] A preparation method for a tire carcass steel wire compound, comprising the steps of:

[0025] (1) One-stage master batching: Add 100 parts of natural rubber, 0.3 parts of B-type peptizer, 45 parts of carbon black, 7 parts of zinc oxide, 1 part of stearic acid, 1 part of anti-aging agent, 1 part of m-benzene 2 parts of diphenol, the rotor speed of the internal mixer is 50 rpm, the pressure of the top bolt is 0.4MPa, the mixing time is 140 seconds, and the glue discharge temperature is 155°C to obtain a section of masterbatch;

[0026] (2) Two-stage master mixing: add one-stage masterbatch and 8 parts of carbon black to the internal mixer, the rotor speed of the internal mixer is 45-55 rpm, the pressure of the top bolt is 0.3MPa, and the mixing time is 50 seconds , the discharge temperature is 150°C, and the second-stage masterbatch is obtained;

[0027] (3) Final refining: add 1 part of second-stage masterbatch, adhesive, 2 parts of insoluble sulfur, 0.5 part of accele...

Embodiment 3

[0029] A preparation method for a tire carcass steel wire compound, comprising the steps of:

[0030] (1) One-stage master batching: Add 100 parts of natural rubber, 0.2 parts of B-type peptizer, 50 parts of carbon black, 8 parts of zinc oxide, 1 part of stearic acid, 3 parts of anti-aging agent, m-benzene 2 parts of diphenol, the rotor speed of the internal mixer is 55 rpm, the pressure of the top bolt is 0.3MPa, the mixing time is 120 seconds, and the glue discharge temperature is 165°C to obtain a section of masterbatch;

[0031] (2) Second-stage master batching: add one-stage masterbatch and 10 parts of carbon black to the internal mixer, the rotor speed of the internal mixer is 55 rpm, the pressure of the top bolt is 0.5 MPa, the mixing time is 110 seconds, and the discharge time is 110 seconds. The glue temperature is 150-165°C to obtain the second-stage masterbatch;

[0032] (3) Final refining: add 4 parts of second-stage masterbatch, binder, 6 parts of insoluble sulfu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com