A kind of preparation method of all-steel radial truck tire traveler glue hanging

A radial tire and bead ring technology is applied to the preparation of all-steel radial tire bead ring rubber, which can solve the problems of copper exposure, wire scrap, poor performance of the coating process, etc., and achieve high breaking strength and wire pull-out force. High and durable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

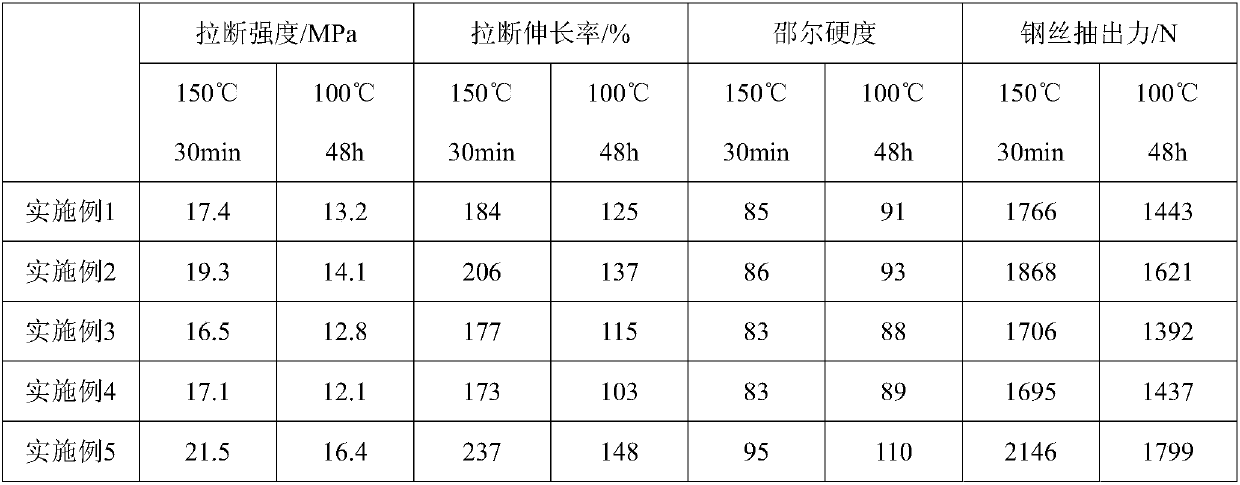

Examples

Embodiment 1

[0018] A preparation method for all-steel radial truck tire traveler glue hanging, comprising the following steps:

[0019] Step 1, in parts by weight, 20 parts of chlorinated rubber, 5 parts of nitrile rubber, 5 parts of methyl vinyl silicone rubber, 3 parts of coumarone resin, 2 parts of white carbon black, 1 part of polyol, emulsified silicone oil 4 parts were mixed and kneaded to obtain rubber compound A;

[0020] Step 2: In parts by weight, 2 parts of carbon black, 1 part of sodium polyacrylate, and 1 part of chlorinated polypropylene are added to rubber compound A, and mixed to obtain rubber compound B;

[0021] Step 3, in parts by weight, add 2 parts of accelerator, 1 part of insoluble sulfur, 2 parts of hexamethylenetetramine, and 0.5 parts of micropowdered silica gel to rubber compound B, knead, and tablet to obtain mixed rubber compound C;

[0022] Step 4, vulcanize the mixed rubber C in a flat vulcanizer, and leave it to stand to obtain.

[0023] Wherein, in step...

Embodiment 2

[0025] A preparation method for all-steel radial truck tire traveler glue hanging, comprising the following steps:

[0026] Step 1, in parts by weight, 24 parts of chlorinated rubber, 7 parts of nitrile rubber, 6 parts of methyl vinyl silicone rubber, 4 parts of coumarone resin, 5 parts of white carbon black, 2 parts of polyol, emulsified silicone oil 6 parts were mixed and kneaded to obtain rubber compound A;

[0027] Step 2: In parts by weight, 3 parts of carbon black, 2 parts of sodium polyacrylate, and 3 parts of chlorinated polypropylene are added to rubber compound A, and mixed to obtain rubber compound B;

[0028] Step 3, in parts by weight, add 3 parts of accelerator, 2 parts of insoluble sulfur, 5 parts of hexamethylenetetramine, and 0.9 parts of micropowdered silica gel to rubber compound B, knead and tablet to obtain mixed rubber compound C;

[0029] Step 4, vulcanize the mixed rubber C in a flat vulcanizer, and leave it to stand to obtain.

[0030] Wherein, in s...

Embodiment 3

[0032] A preparation method for all-steel radial truck tire traveler glue hanging, comprising the following steps:

[0033] Step 1, in parts by weight, 35 parts of chlorinated rubber, 8 parts of nitrile rubber, 7 parts of methyl vinyl silicone rubber, 9 parts of coumarone resin, 6 parts of white carbon black, 3 parts of polyol, emulsified silicone oil 6 parts were mixed and kneaded to obtain rubber compound A;

[0034] Step 2: In parts by weight, 3 parts of carbon black, 4 parts of sodium polyacrylate, and 3 parts of chlorinated polypropylene are added to rubber compound A, and mixed to obtain rubber compound B;

[0035] Step 3, in parts by weight, add 4 parts of accelerator, 3 parts of insoluble sulfur, 5 parts of hexamethylenetetramine, and 1.5 parts of micropowdered silica gel to the rubber compound B, knead, and tablet to obtain the mixed rubber compound C;

[0036] Step 4, vulcanize the mixed rubber C in a flat vulcanizer, and leave it to stand to obtain.

[0037] Wher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com