Nano material modified rubber V strip

A technology of modified rubber and nano-materials, applied in the field of nano-material modified rubber V-belts and its manufacturing, to achieve the effects of improving the performance of finished products, overcoming dust pollution, compressing permanent deformation and improving tear performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

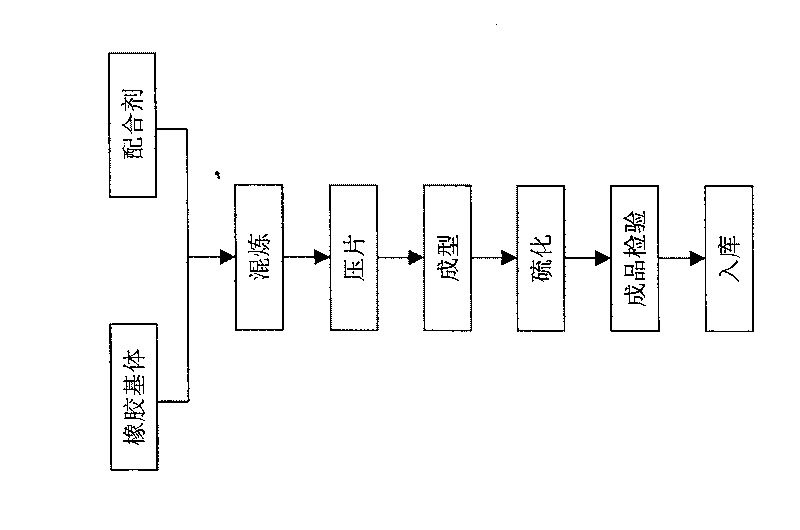

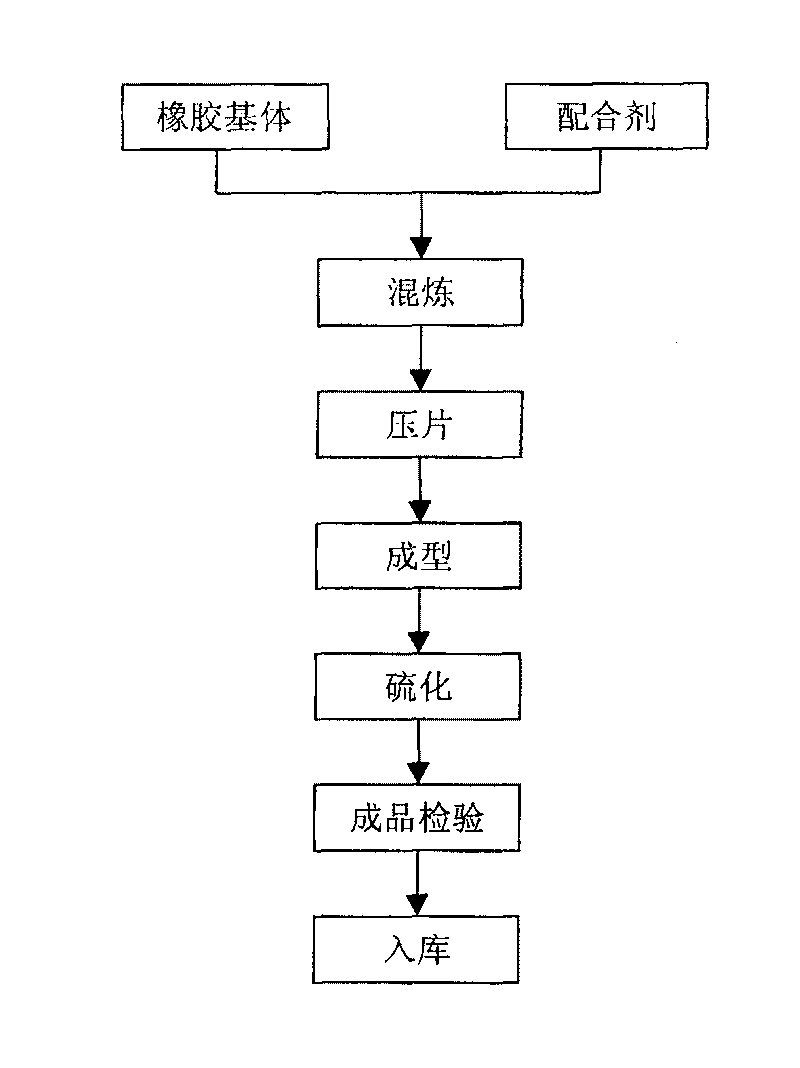

Method used

Image

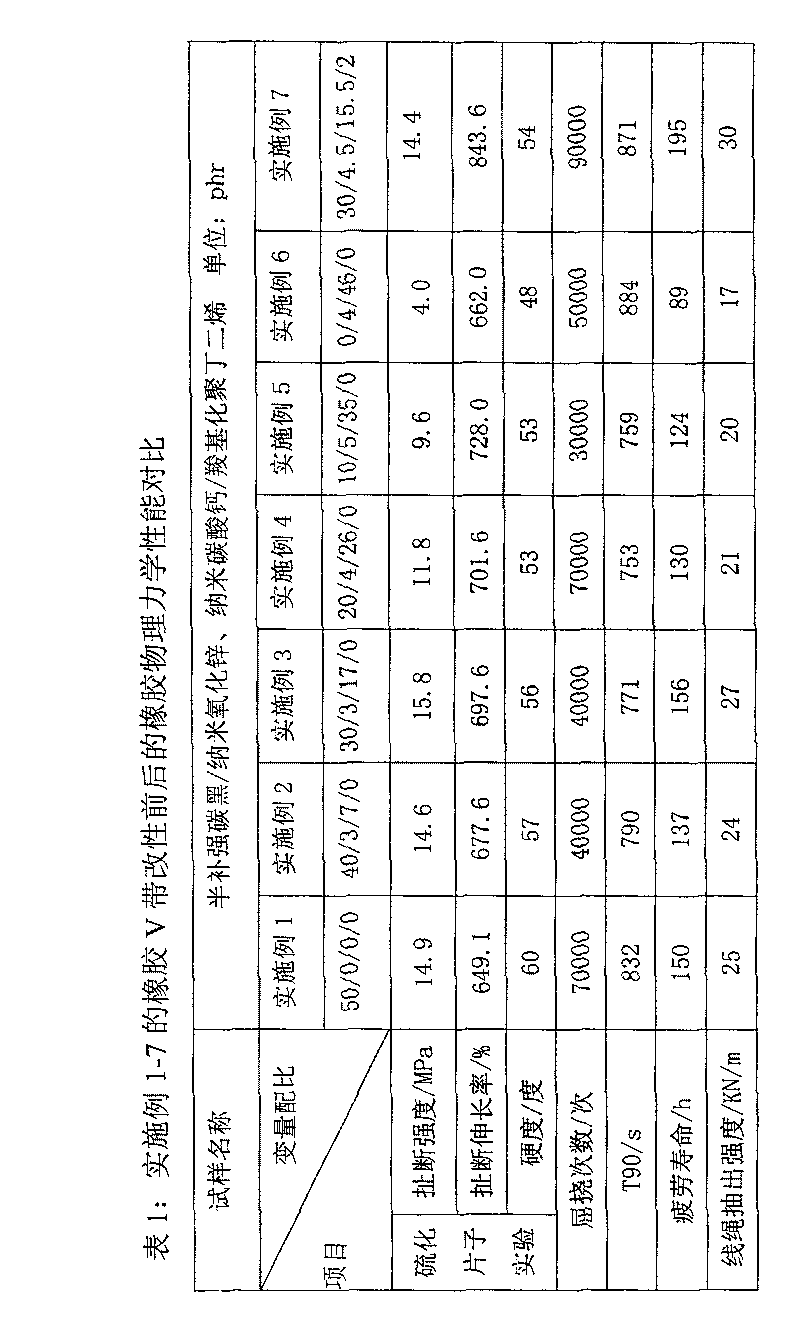

Examples

Embodiment 1

[0034] In the present embodiment, the selected main raw material, compounding agent and formula ratio thereof are as follows:

[0035] In parts by mass, rubber matrix: 100; sulfur: 2.0; accelerator: 0.8; stearic acid: 1.5; antioxidant: 2.0; carbon black: 50.0; coumarone: 3.0; pine tar: 5.0.

[0036] First carry out the rubber mixing process, first add the rubber matrix, and then select sulfur, accelerator, stearic acid, anti-aging agent, carbon black and softener in batches according to the conventional mixing process for mixing, and then roll out the sheet and shape it , vulcanization, make the rubber V-belt of the present invention.

Embodiment 2

[0038] In the present embodiment, the selected main raw material, compounding agent and formula ratio thereof are as follows:

[0039] In parts by mass, rubber matrix: 100; sulfur: 2.0; accelerator: 0.8; nano-zinc oxide: 3.0; stearic acid: 1.5; antioxidant: 2.0; carbon black: 40.0; nano-calcium carbonate: 7.0; coumarone: 3.0; Pine Tar: 5.0.

[0040] First carry out the rubber mixing process, first add the rubber matrix, then add nano-zinc oxide, nano-calcium carbonate, and then select sulfur, accelerator, stearic acid, anti-aging agent, carbon black and softener in batches according to the conventional mixing process. Mixing, calendering, molding, and vulcanization to obtain the rubber V-belt of the present invention.

Embodiment 3

[0042] In the present embodiment, the selected main raw material, compounding agent and formula ratio thereof are as follows:

[0043] In parts by mass, rubber matrix: 100; sulfur: 2.0; accelerator: 0.8; nano-zinc oxide: 3.0; stearic acid: 1.5; antioxidant: 2; carbon black: 30.0; nano-calcium carbonate: 17.0; coumarone: 3.0; Pine Tar: 5.0.

[0044] Process step is with embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com