An environmental protection slope protection cement delivery pipe

A technology of environmental protection and conveying pipes, which is applied in the processing of building materials, construction, building construction, etc., and can solve the problems of increased cost of mountain protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

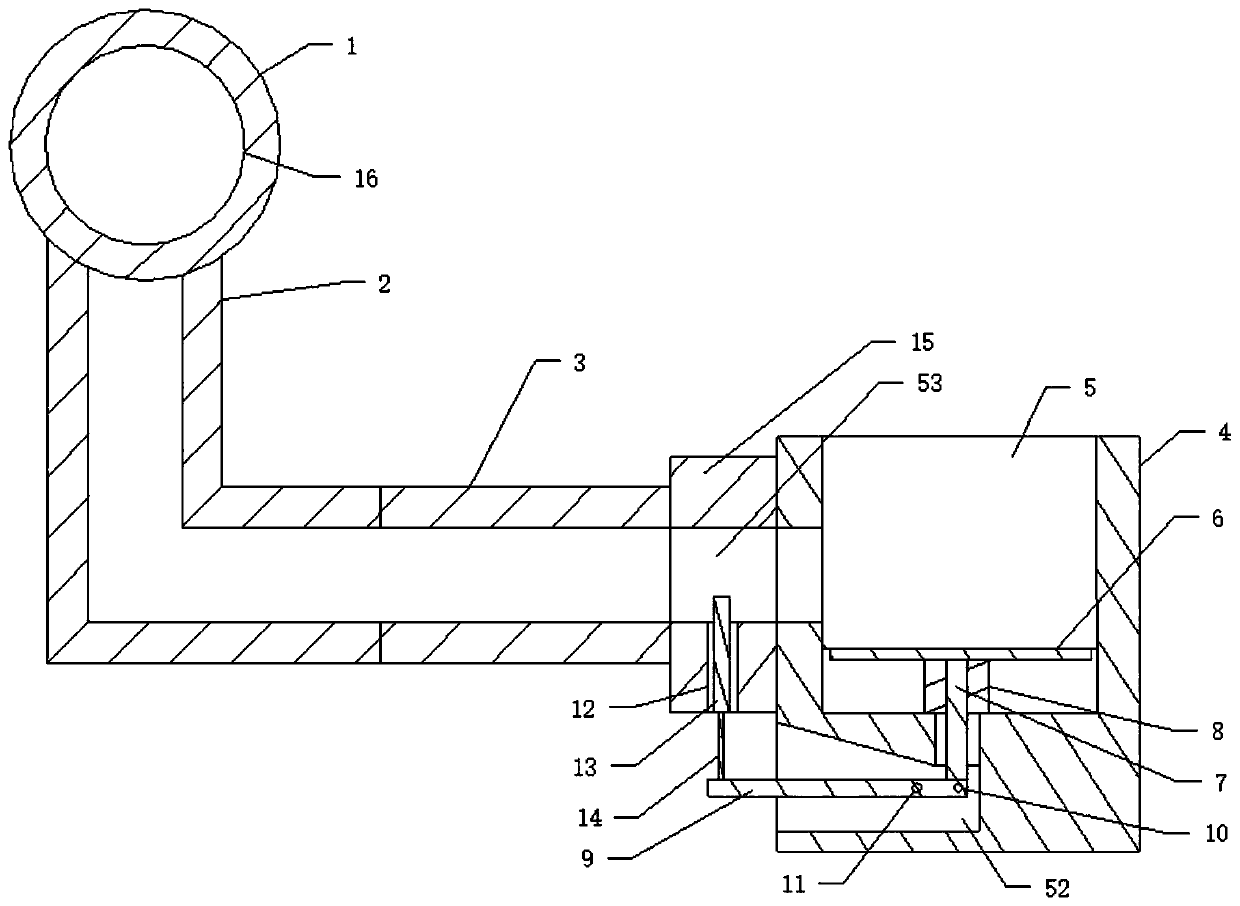

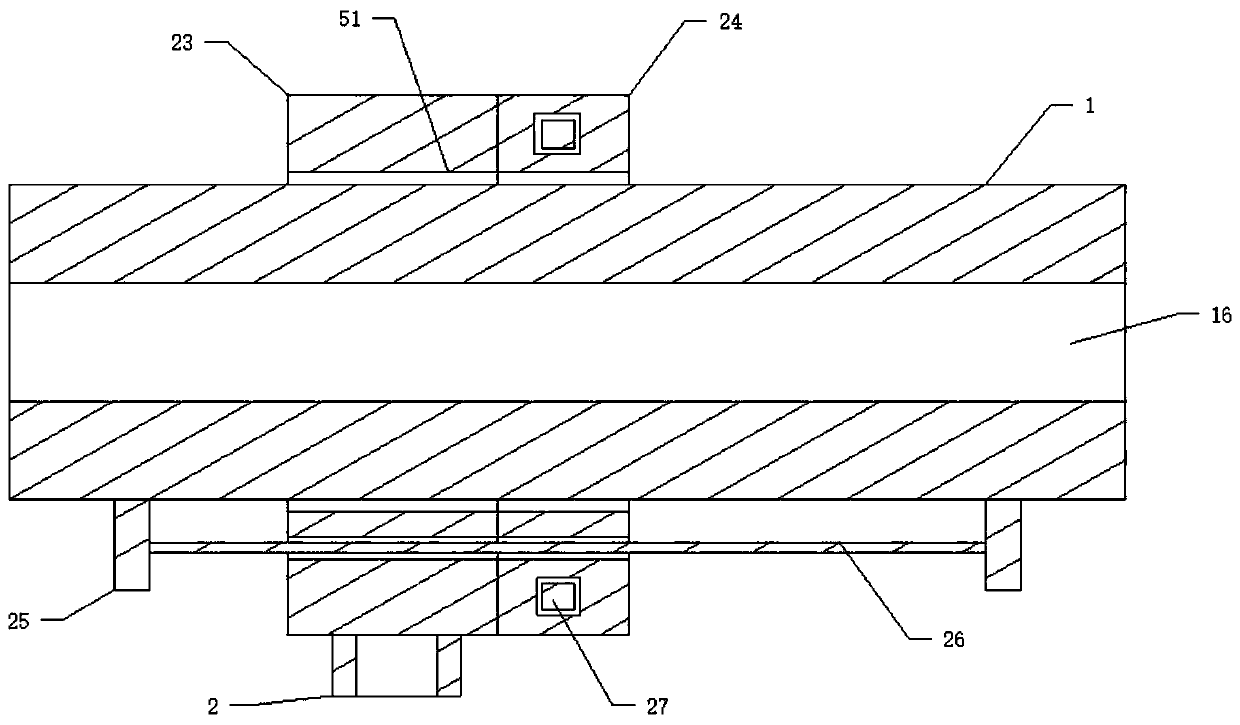

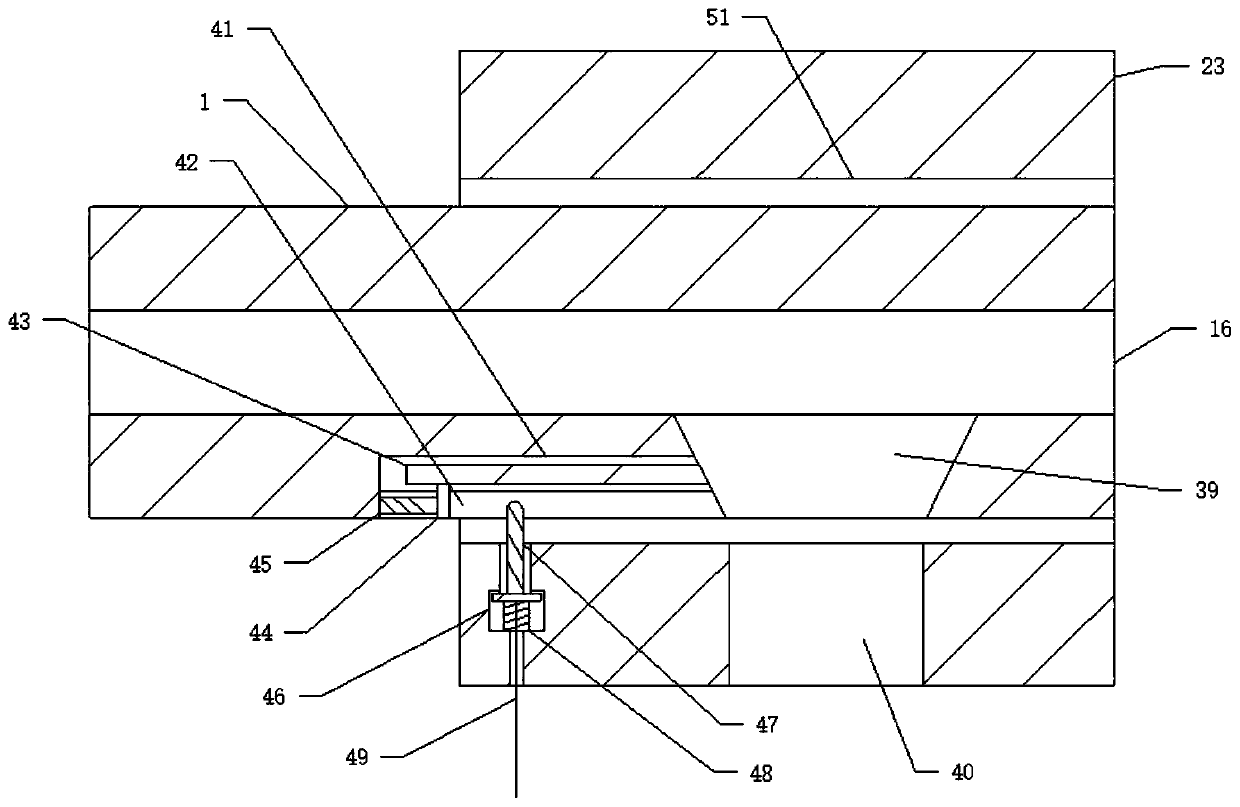

[0026] Such as Figure 1 to Figure 6 As shown, an environmental protection slope protection cement delivery pipe includes a first delivery pipe 1, a row of sliding control sleeves 23 is arranged on the first delivery pipe 1, and a row of sliding control sleeves 23 is arranged on the first delivery pipe 1 Discharge port 39, the sliding of the control sleeve 23 controls the closing of the discharge port 39, and the control sleeve 23 is respectively connected with a second conveying pipe 2 corresponding to the discharge port 39 .

[0027] The cement can be transported through the first conveying pipe 1, so that the first conveying pipe 1 can be erected at a high place on the hillside, and a row of sliding control sleeves 23 are arranged on the first conveying pipe 1, the The number of control sleeves 23 can be set according to the needs of the design, and a row of discharge ports 39 is arranged on the first conveying pipe 1, and the number of the discharge ports 39 can be set ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com