Automatic spraying device

A technology of automatic spraying and electromagnetic devices, applied in the direction of spraying devices, spraying devices, liquid spraying devices, etc., can solve problems such as air pollution, excessive paint spraying, difficult adhesion, etc., and achieve the effect of improving processing quality and ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0034] In order to achieve the above object, the technical scheme adopted in the present invention is as follows:

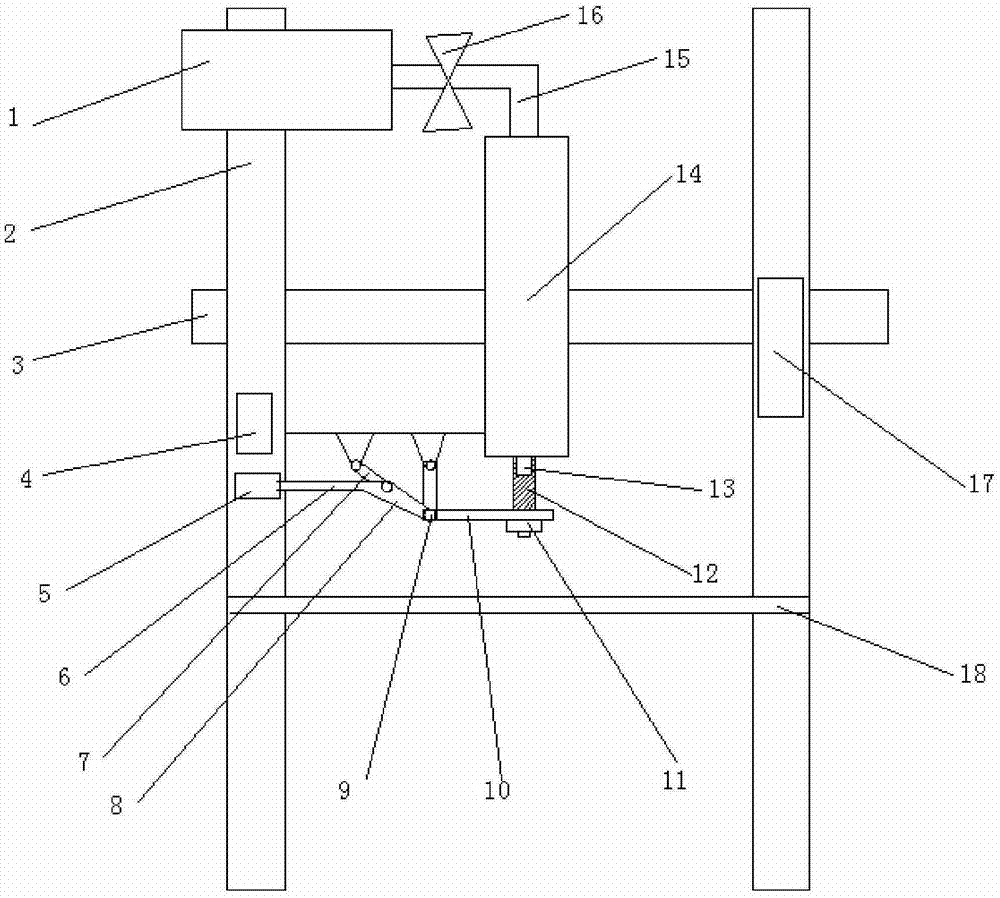

[0035] The automatic spraying device includes: storage tank 1, mounting plate leg 2, mounting plate 3, electromagnetic device 4, permanent magnet 5, handle 6, rod A7, rod B8, hinge 9, rod C10, fastening nut 11, nozzle cover 12. Nozzle 13, paint spray tank 14, paint spray tube 15, controllable valve 16, control device 17 and production line 18, the storage tank 1 is fixed on the left mounting plate leg 2, and is connected with the paint spray tank 14 through the paint spray tube 15, The paint spray pipe 15 is provided with a controllable valve 16, the paint spray can 14 is fixed on the mounting plate 3, and its lower end is provided with a nozzle 13, the electromagnetic device 4 is fixed on the leg 2 of the left mounting plate, and the end of the handle 6 is fixed with a permanent magnet 5, And connected with the rod B8, the two ends of the rod B8 are respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com