Multistage fracturing pitching control tool

A technology for controlling tools and fracturing, which is applied in the direction of production fluid, wellbore/well components, earthwork drilling and production, etc. It can solve the problem of limited number of fracturing layers, shorten fracturing operation time, and avoid fracturing operation failure , the effect of reducing the risk of operational errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further explained below in conjunction with the drawings:

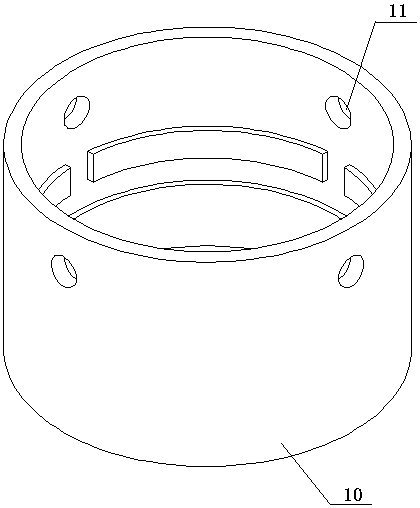

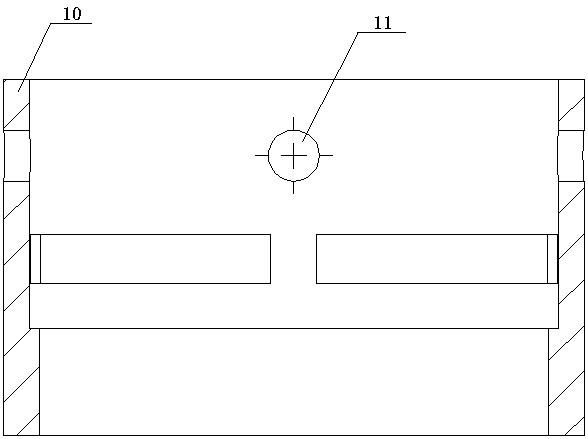

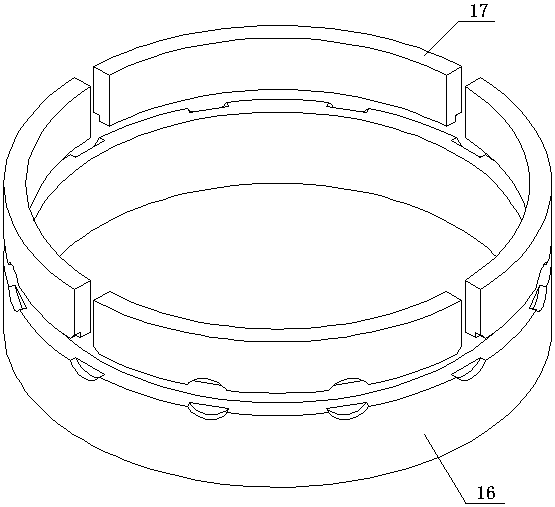

[0021] Combine figure 1 , figure 2 , image 3 , Figure 4 As shown, this multi-stage fracturing ball control tool includes a fracturing port control part and a variable diameter ball seat control part. The fracturing port control part is controlled by the variable diameter ball seat control part. The control part of the ball seat is connected by cylinder Ⅱ8.

[0022] The fracturing port control part includes a cylinder tube I22, the upper part of the cylinder tube I22 is connected to the top tube 5, the upper end of the rubber tube shaft 3 is connected to the upper joint 1, and the lower end of the rubber tube shaft 3 is arranged between the top tube 5 and the cylinder tube I22, and the rubber tube shaft 3 The lower end is fastened to the outside of the cylinder tube I 22, a plurality of rubber cylinders 4 are sequentially placed outside the rubber cylinder shaft 3, and the rubber cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com