Circuit board automatic detection equipment

An automatic detection and circuit board technology, applied in sorting and other directions, can solve complex and multi-structure problems, and achieve the effects of improving detection efficiency, optimizing complexity and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

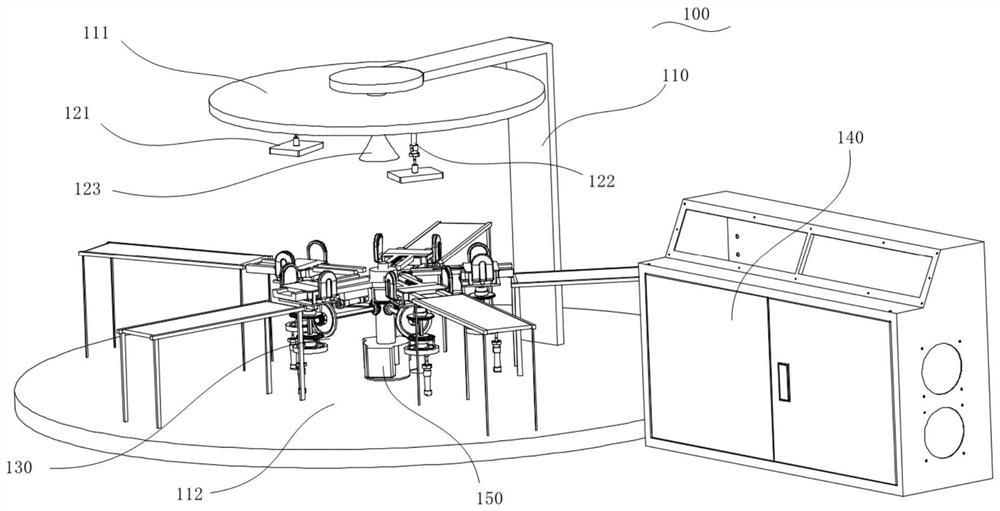

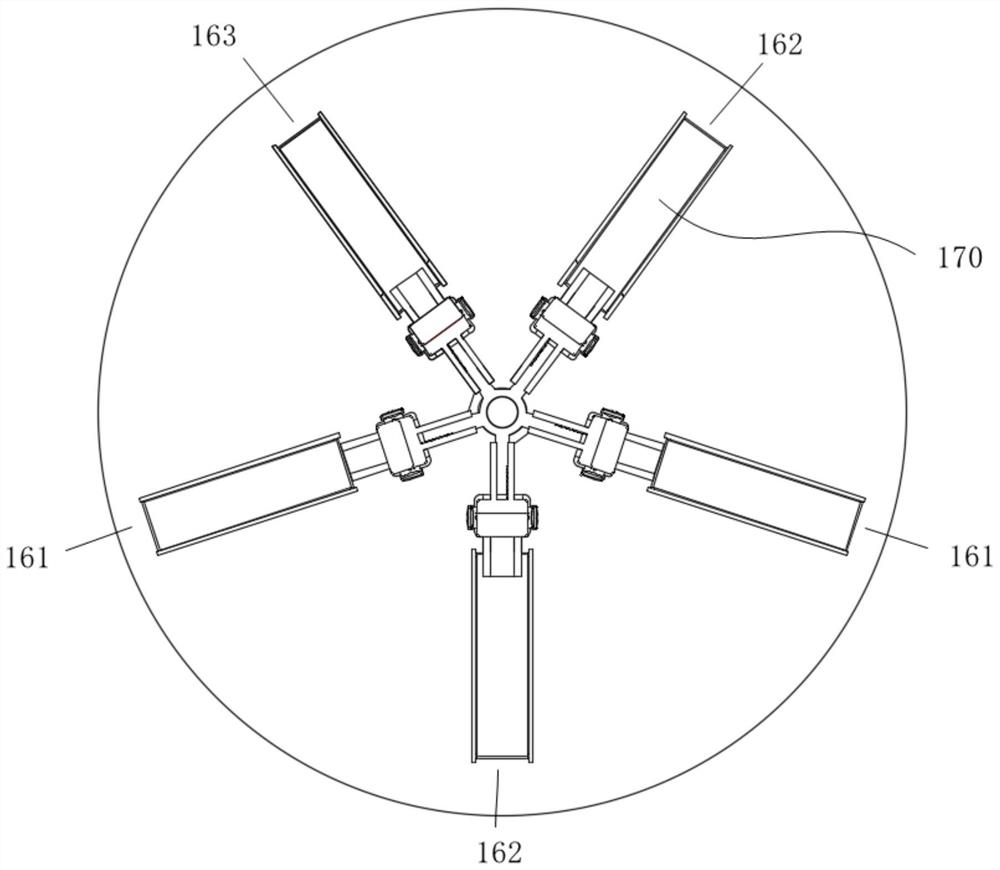

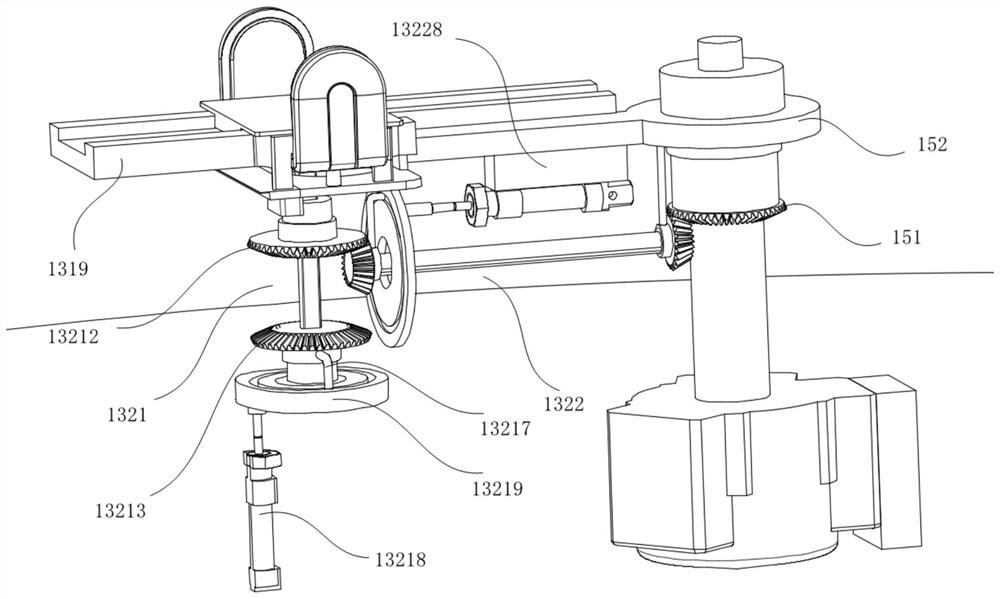

[0044] Such as Figure 1-11 As shown, a kind of circuit board automatic detection equipment of the present invention comprises frame 110, motor 150, several conveyer belts 170, several feeding devices 130, detection device, control box 140, and described frame 110 includes upper cover 111 and chassis 112, the control box 140 is located at one side of the frame 110, the detection device is located at the lower side of the upper cover 111 of the frame 110, the motor 150 is located at the center of the chassis 112 of the frame 110, several of the The conveying device 130 is circumferentially arranged around the motor 150, and is rotationally connected with the motor 150. The motor 150 uniformly drives a plurality of the conveying devices 130 to move, and the several conveyor belts 170 are respectively located on the The outside of the device can transport the circuit boards to be inspected or transport away the inspected circuit boards. The conveying device 130 includes a clampin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com