Novel steam self-priming fluid mixing integral foam pump and bathroom device applying same

A fluid mixing, integrated technology, applied in the field of foam pumps, can solve the problems of high cost, complex structure, large volume, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, where the schematic embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

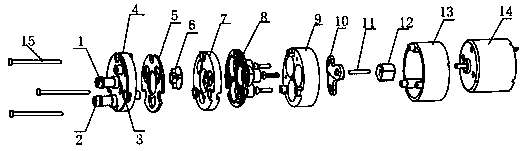

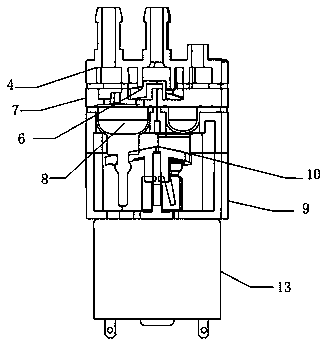

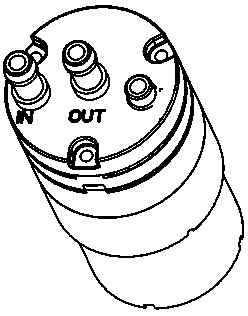

[0017] refer to Figure 1 to Figure 3 , The present invention provides a novel water-air self-absorbing fluid mixing integrated foam pump and its sanitary device.

[0018] Its technical solution is: a new type of water-air self-priming fluid mixing integrated foam pump, which is characterized in that it includes a gas-liquid self-priming cylinder 8, which is specially made of high-elastic silica gel material resistant to acid, alkali and salt. 3 independent self-priming cylinders are arranged on it, the gas-liquid mixing connection cover 7 arranged on the upper end of the gas-liquid self-suction cylinder, the through hole communicated with the gas-liquid fluid provided on it, the gas-liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com