Fishbone-shaped novel plate heat exchanger plate

A plate heat exchanger, fishbone-shaped technology, applied in the field of new plate heat exchanger plates, can solve the problems of heat exchange effect, uniformity, and fluid distribution, etc., to achieve optimized comprehensive performance, uniform flow distribution, The effect of reducing flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

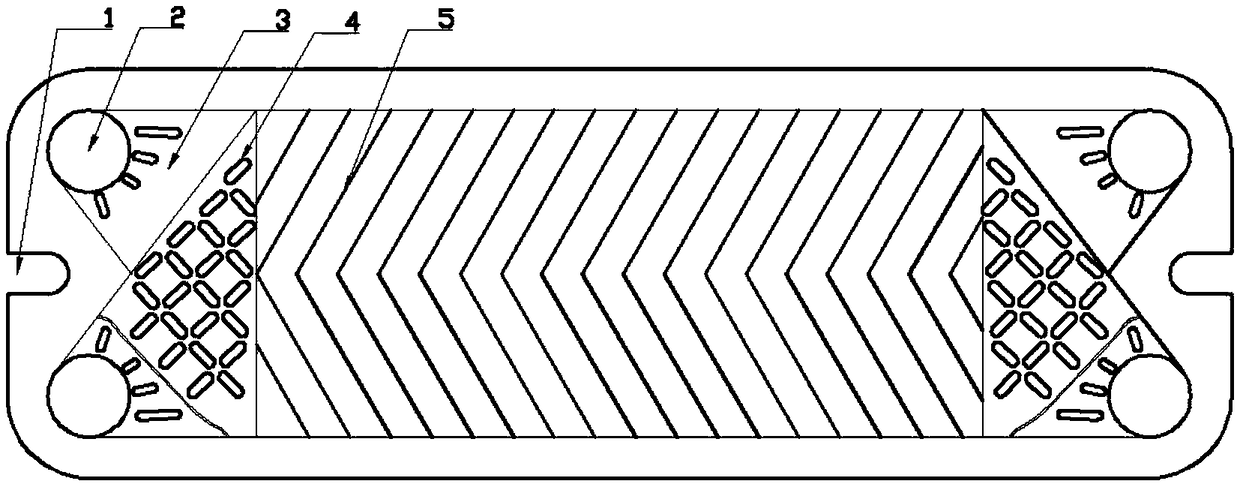

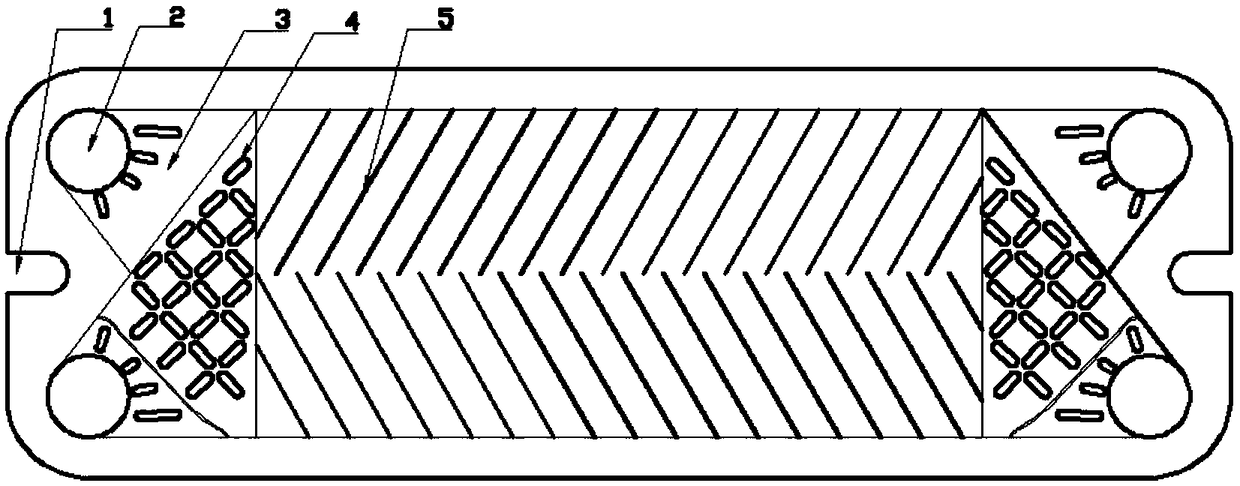

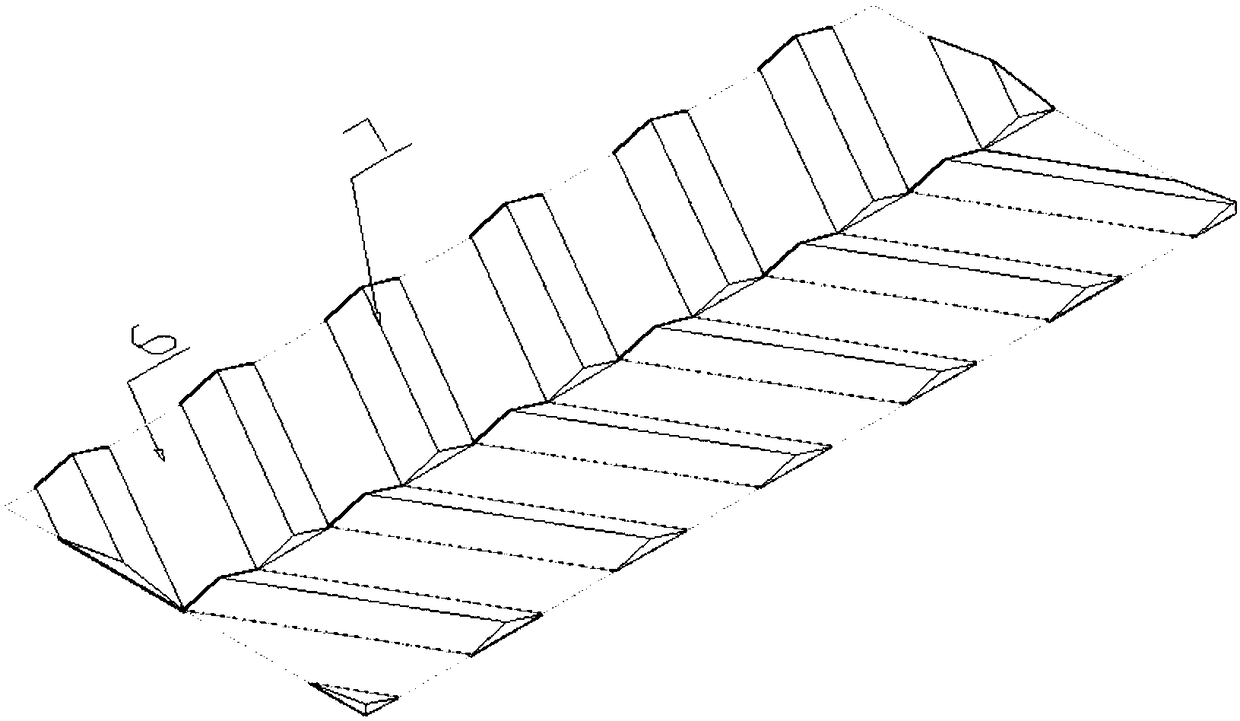

[0013] combine figure 2 , image 3 , a new fishbone-shaped plate heat exchanger plate, including a plate body, the plate body is provided with positioning holes 1, corner holes 2, diversion area 3, diversion area 4, heat exchange area 5. The positioning holes 1 are located at both ends of the main body of the sheet for positioning. There are four corner holes 2 respectively located on the four corners of the plate main body, and the heat exchange medium flows through the corner holes 2 . The flow guide area 3 guides the heat exchange medium to the flow distribution area 4 . The split area 4 splits the heat exchange medium to different areas of the heat exchange area 5 . Corrugations 11 are arranged on the heat exchange area 5 along the flow direction of the heat exchange medium,

[0014] When the heat exchange medium flows into the plate through the corner hole 2, passes through the diversion area 3 and the diversion area 4, and flows into the heat exchange area 5, where ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com