Monitoring method and system for battery testing workshop

A battery testing and monitoring system technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of low battery testing efficiency and low intelligence, and achieve the effect of realizing intelligent testing and improving testing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

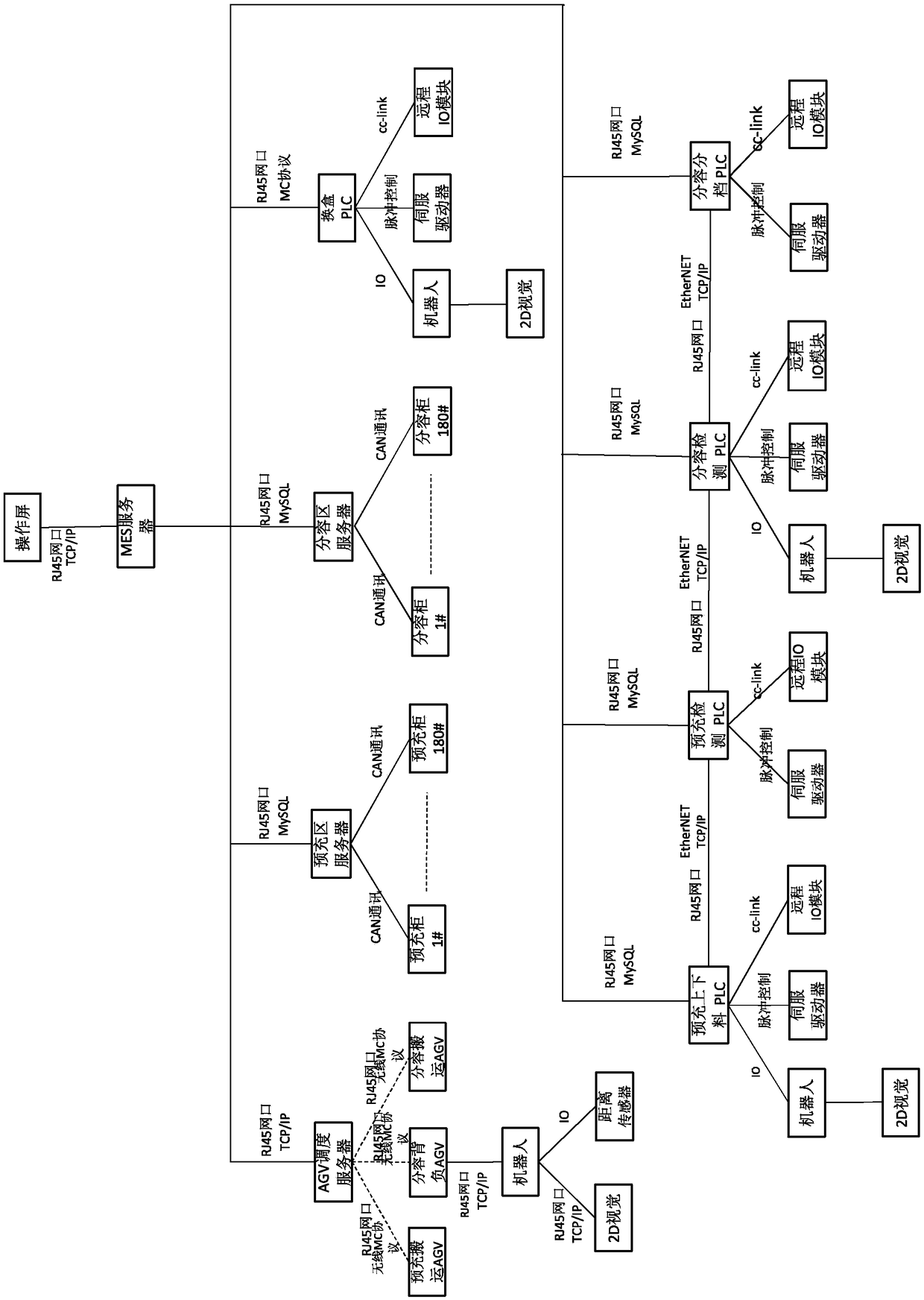

[0036] A monitoring system for a battery test workshop, applied to a battery test workshop, the battery test workshop includes a pre-charging area, a first aging area, a first resting area, a capacity division area, a second aging area, and a second resting area and binning area, refer to figure 1 , figure 1 It is a schematic diagram of a specific embodiment of a monitoring system for a battery testing workshop of the present invention, and the monitoring system includes

[0037] The AGV scheduling server is used to obtain the status information of the AGV car. The status information of the AGV car includes the working status information of the AGV car and the location information of the AGV car. The method of obtaining information belongs to the prior art and will not be repeated here;

[0038] The ser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com