Rat-proof optical cable capable of being recognized easily, and production technology and die for optical cable

An easy-to-identify, optical cable technology, which is applied in the field of optical cables, can solve the problems of hard nylon sheath layer of optical cables, cannot be left on the surface of optical cables, and cannot identify the ownership of optical cables, etc., to achieve enhanced bite resistance, superior rodent resistance, and improved construction efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

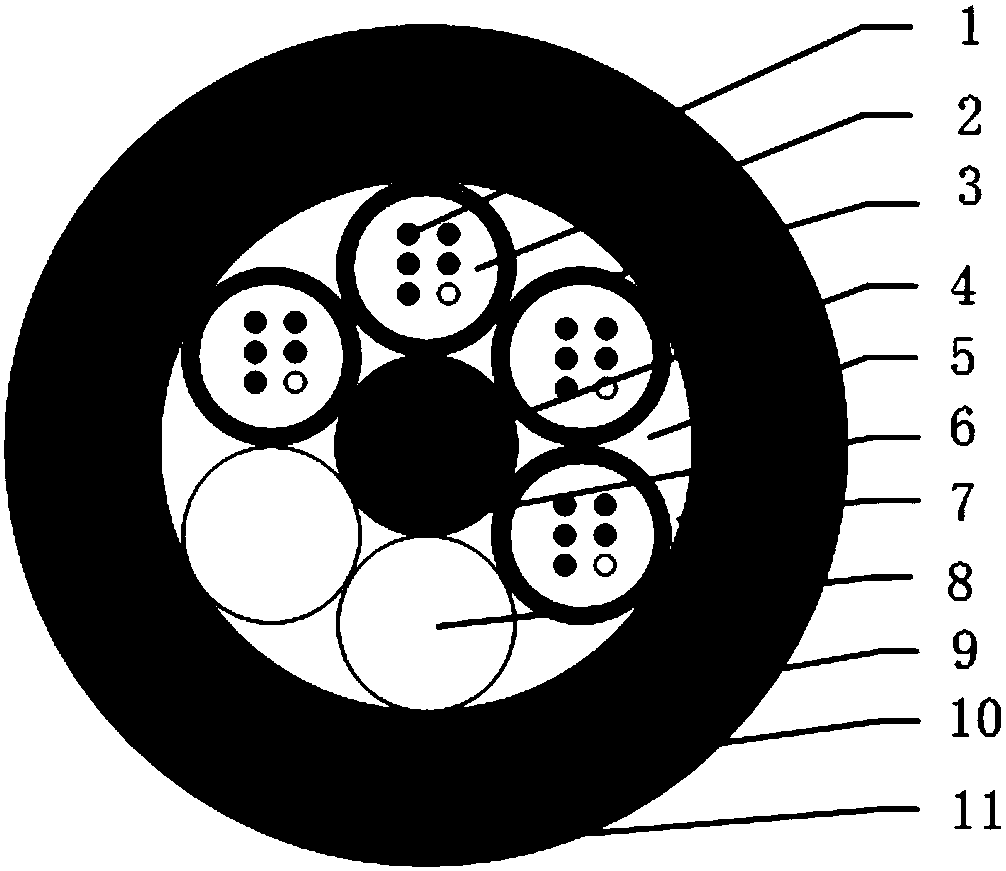

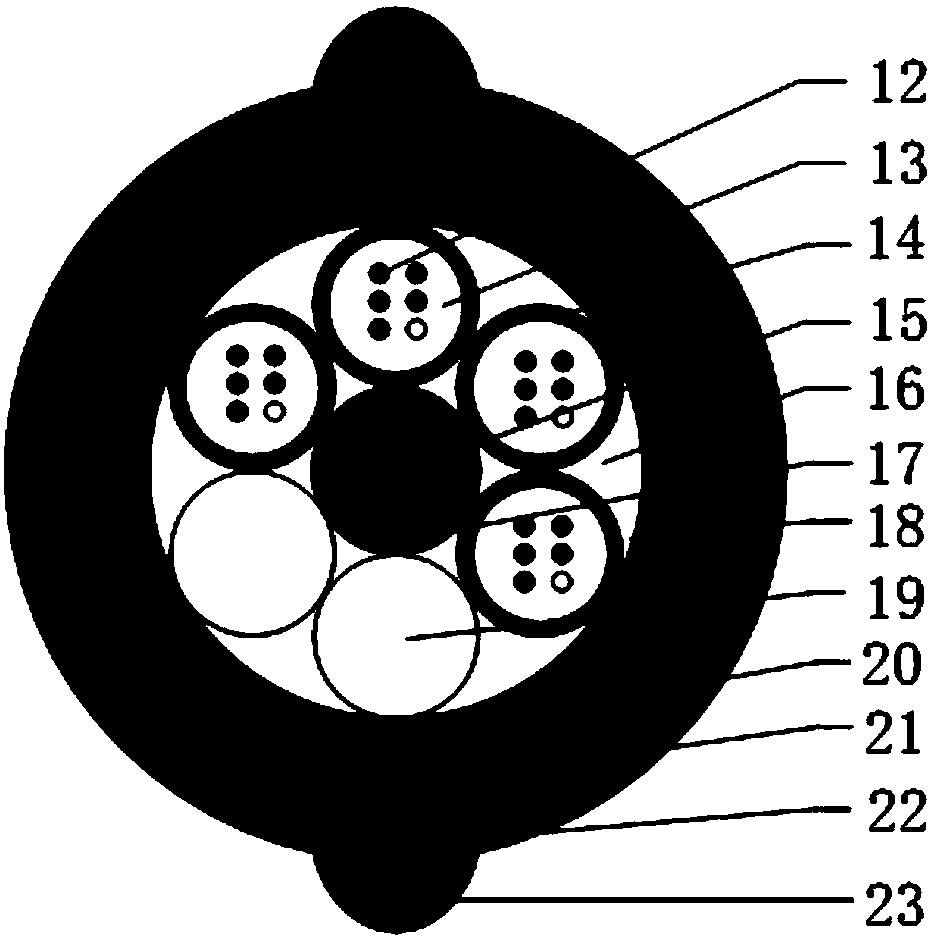

[0032] The easy-to-identify anti-rat optical cable of the present embodiment, such as figure 2 As shown, it includes a cable core, and the outside of the cable core is provided with a longitudinal cladding steel strip 20 , a polyethylene sheath 21 and a nylon sheath 22 arranged in sequence, and the nylon sheath 22 has an identification protrusion 23 outside.

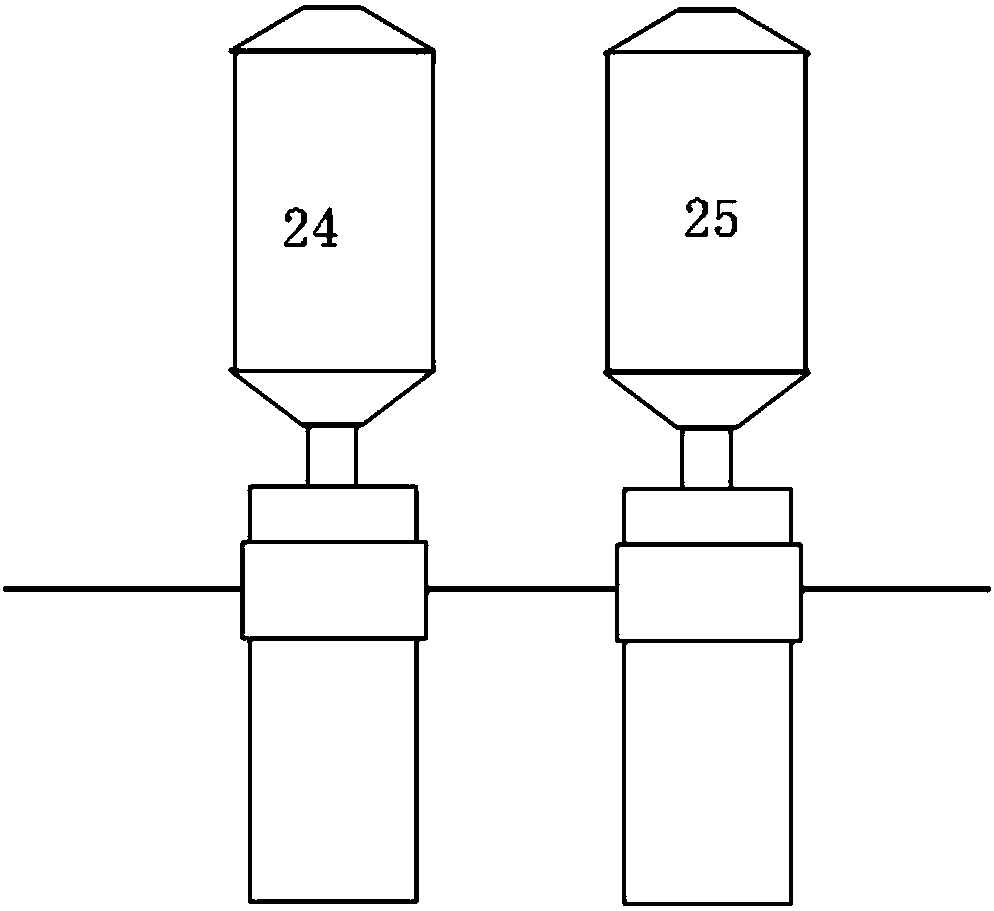

[0033] The polyethylene sheath 21 and the nylon sheath 22 adopt a double-head sheath production device, and the polyethylene sheath 21 has a grafting agent in the material.

[0034] Hot-melt glue is provided at the joints of the steel strips 20 .

[0035] The process for the production of easy-to-identify rodent-proof optical cables is used to produce the above-mentioned optical cables, comprising the following steps

[0036] Step 1, cable core processing;

[0037] Step 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com