Sealing assembly for toner cartridge, toner cartridge and recycling method thereof

A technology for sealing components and toner cartridges, which is applied to the electrical recording process applying charge patterns, equipment and instruments using the electrical recording process applying charge patterns, etc. Large interaction force and other problems, to achieve the effect of easy recycling and manufacturing, reducing interaction force, and simple and convenient process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

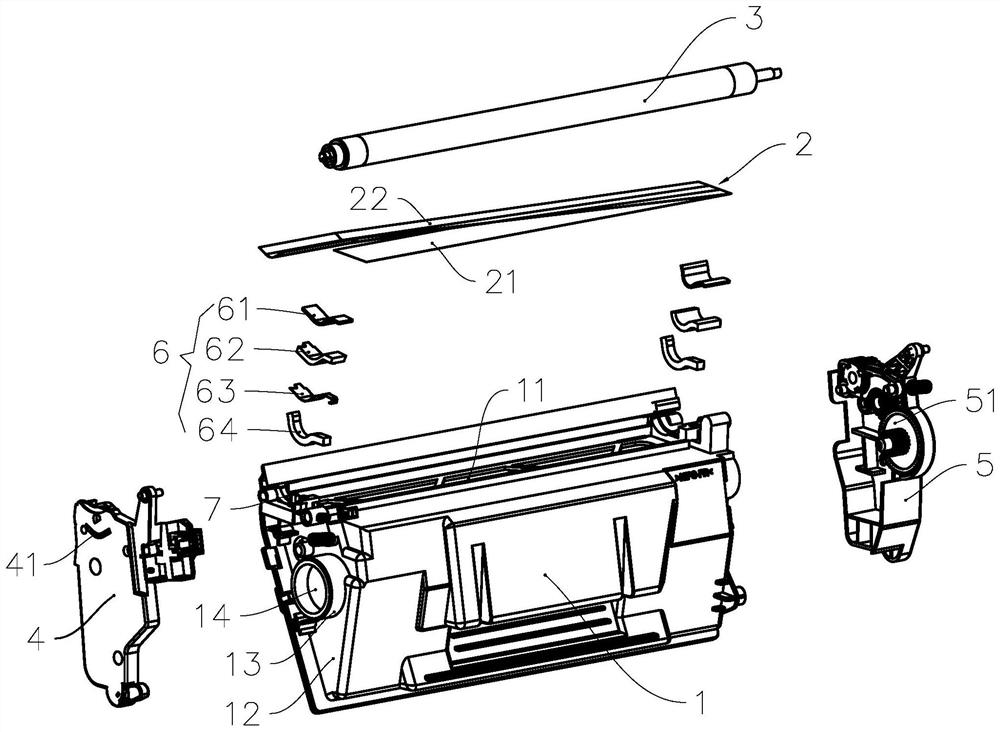

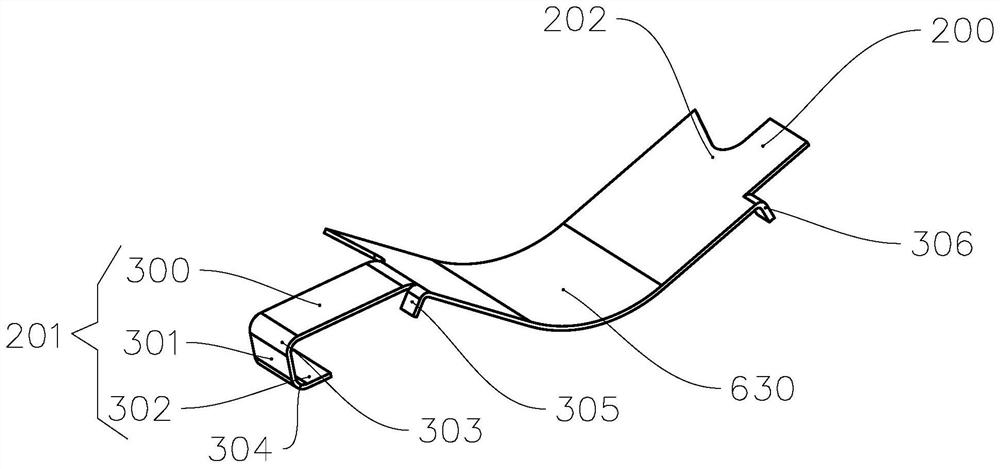

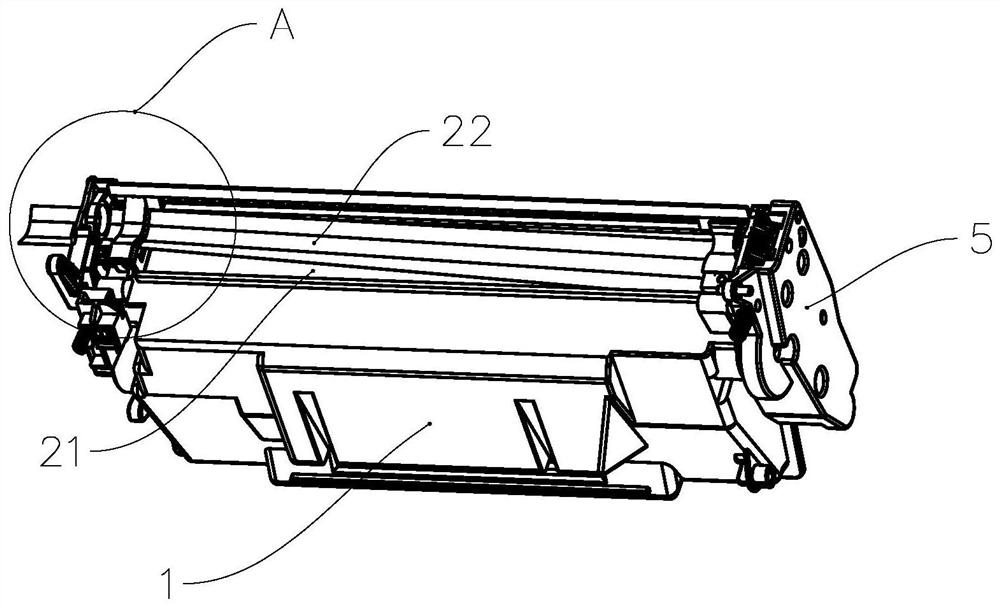

[0036] See attached figure 1 , attached image 3 , attached Figure 4 And attached Figure 7 , The toner cartridge of the present invention includes a powder bin 1 , a sealing film 2 arranged at the powder outlet 11 of the powder bin 1 , and a developing roller 3 arranged above the powder outlet 11 . A first end cover 4 and a second end cover 5 are respectively provided on both sides of the powder bin 1 , a sealing film pulling port 41 is provided on the first end cover 4 , and a driving gear 51 is provided on the inner side of the second end cover 5 . The developing roller 3 is horizontally arranged between the first end cover 4 and the second end cover 5, and a sealing assembly 6 is provided below the end of the developing roller 3 near the sealing film pulling port 41, and the sealing assembly 6 is in contact with the outer peripheral surface of the developing roller 3. , the sealing assembly 6 is also arranged in a groove 7 on the surface of the powder bin 1 . The seal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com