Bullet train set sound failure diagnosis system and diagnosis method

A fault diagnosis system and EMU technology, applied in general control systems, control/regulation systems, testing/monitoring control systems, etc., can solve the problem that limit standards cannot be matched, evaluation results cannot be quantitatively measured, and monitoring results are affected by subjective factors interference and other problems, to achieve the effect of relative noise enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific implementation method of the present invention will be described in detail below in conjunction with the accompanying drawings.

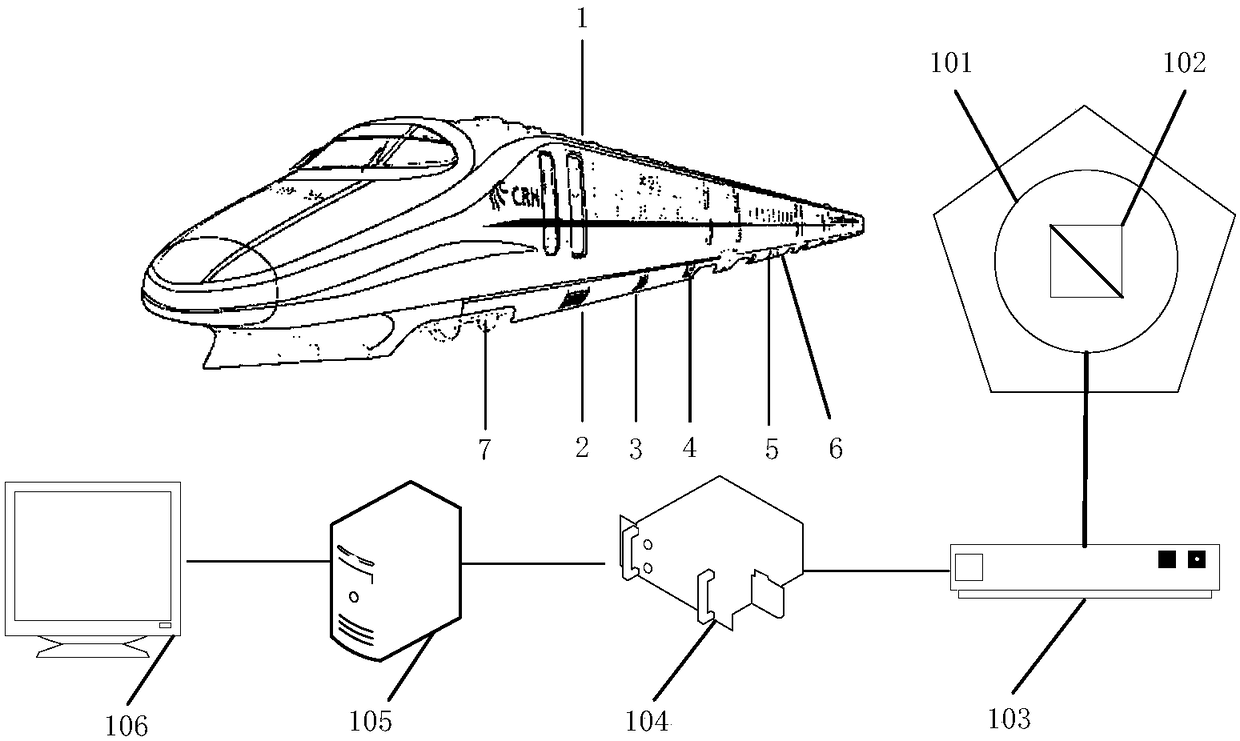

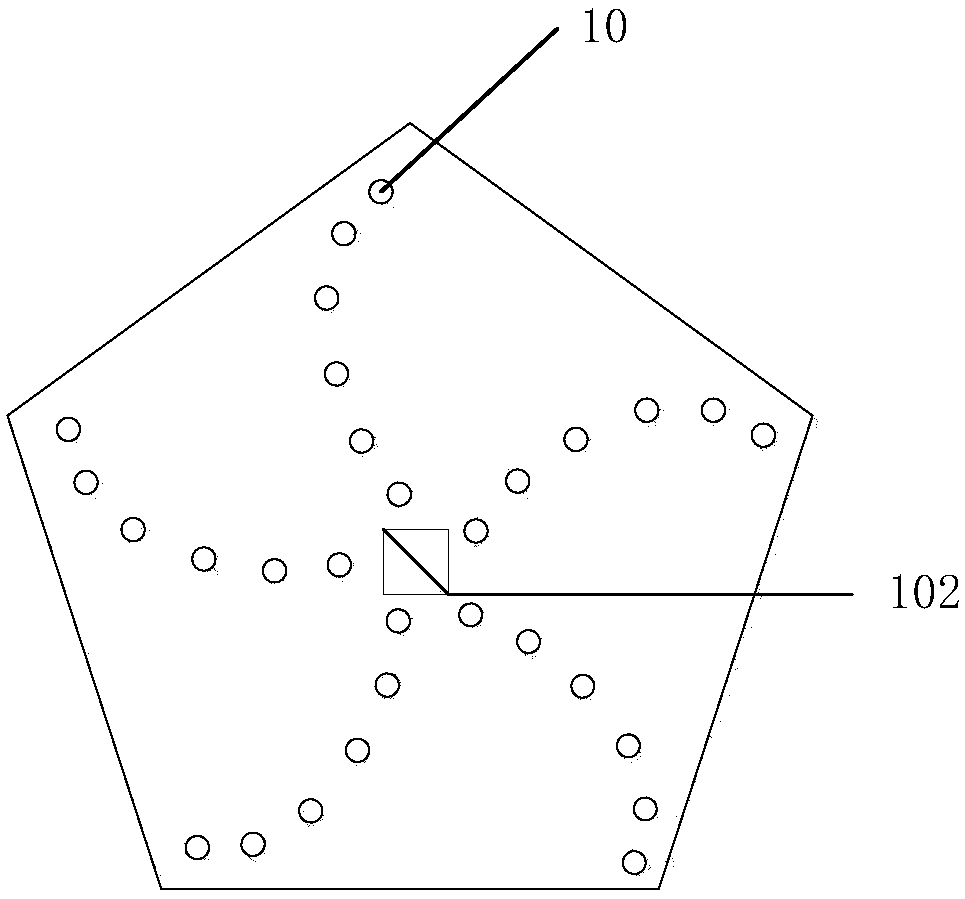

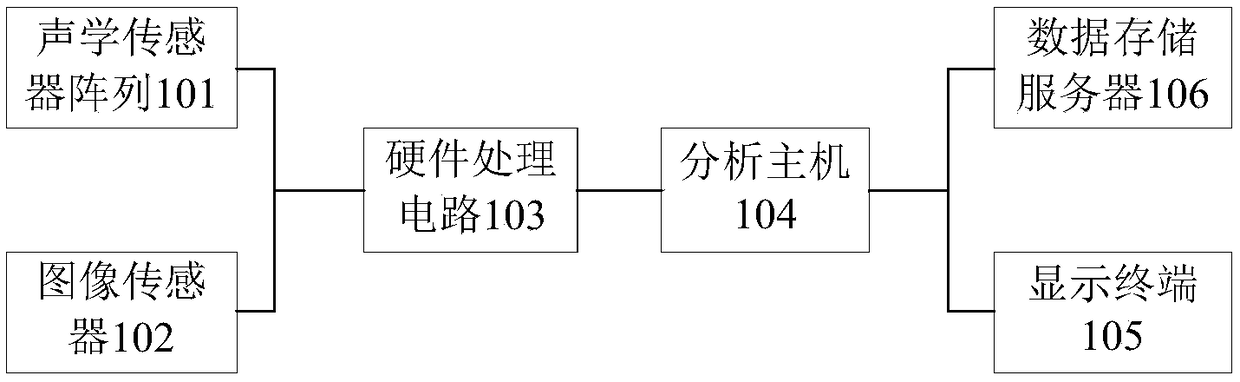

[0037] The invention discloses an EMU sound fault diagnosis system, such as figure 1 and figure 2 As shown, it includes an acoustic sensor array 101 , an image sensor 102 , a hardware processing circuit 103 , an analysis host 104 , a data storage server 105 , and a display terminal 106 .

[0038] The acoustic sensor array 101 and the image sensor 102 are used to collect the acoustic and image information of the EMU 1 under the dynamic motion and static power-on states, and transmit it to the hardware processing circuit 103 to complete the preprocessing of the sound and image information, and then wirelessly transmit the information To the analysis host 104, the analysis host 104 performs fault analysis and judgment on the preprocessed acoustic and image information, and the analyzed and identified fault information can be prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com