Method for producing metal nanoparticles and metallic sulfide nanoparticles using recombinant microorganisms

A technology of metal nanoparticles and recombinant microorganisms, applied in biochemical equipment and methods, preparation of sulfide/polysulfide, metallothionein, etc., can solve the problems of unfavorable production cost and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

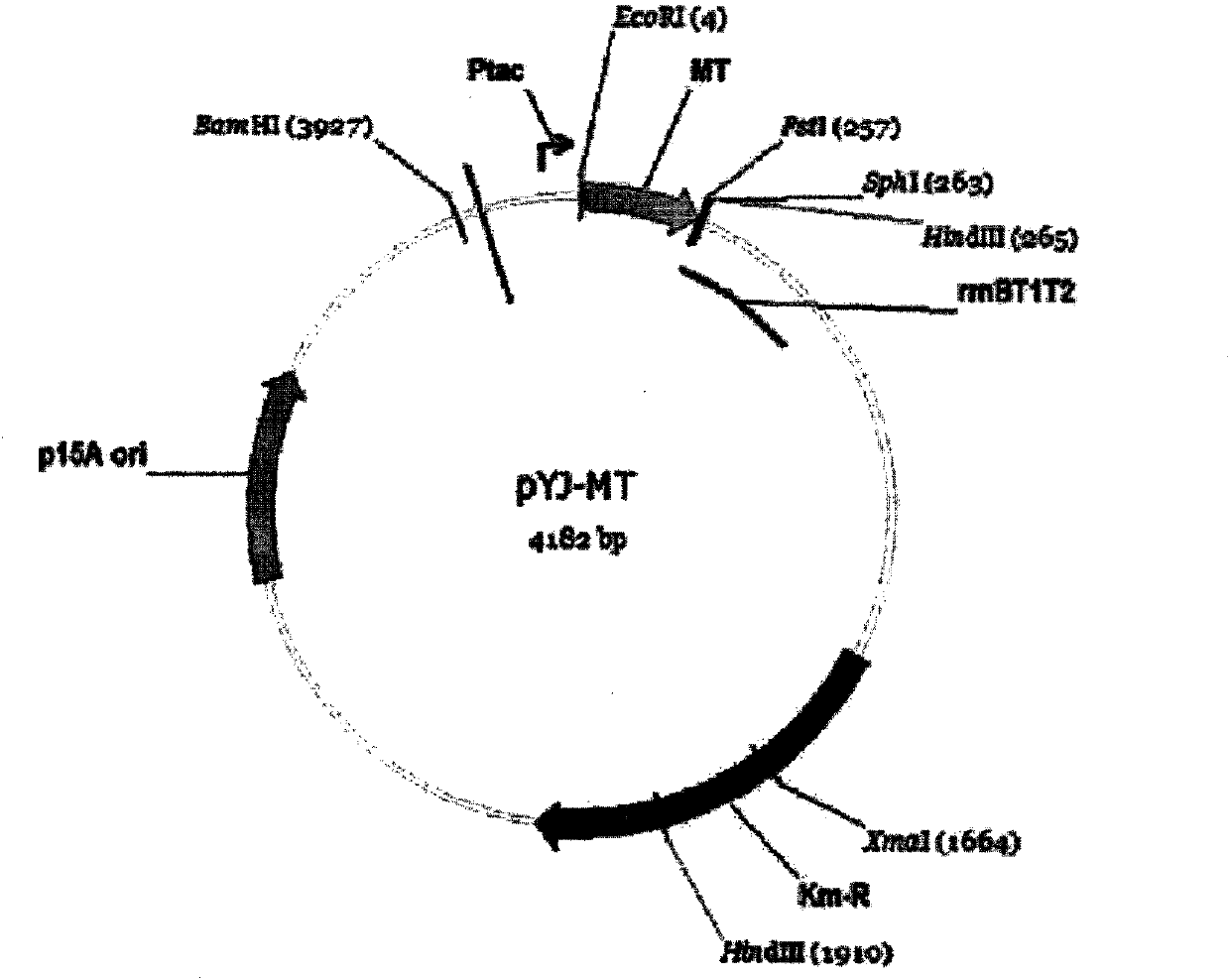

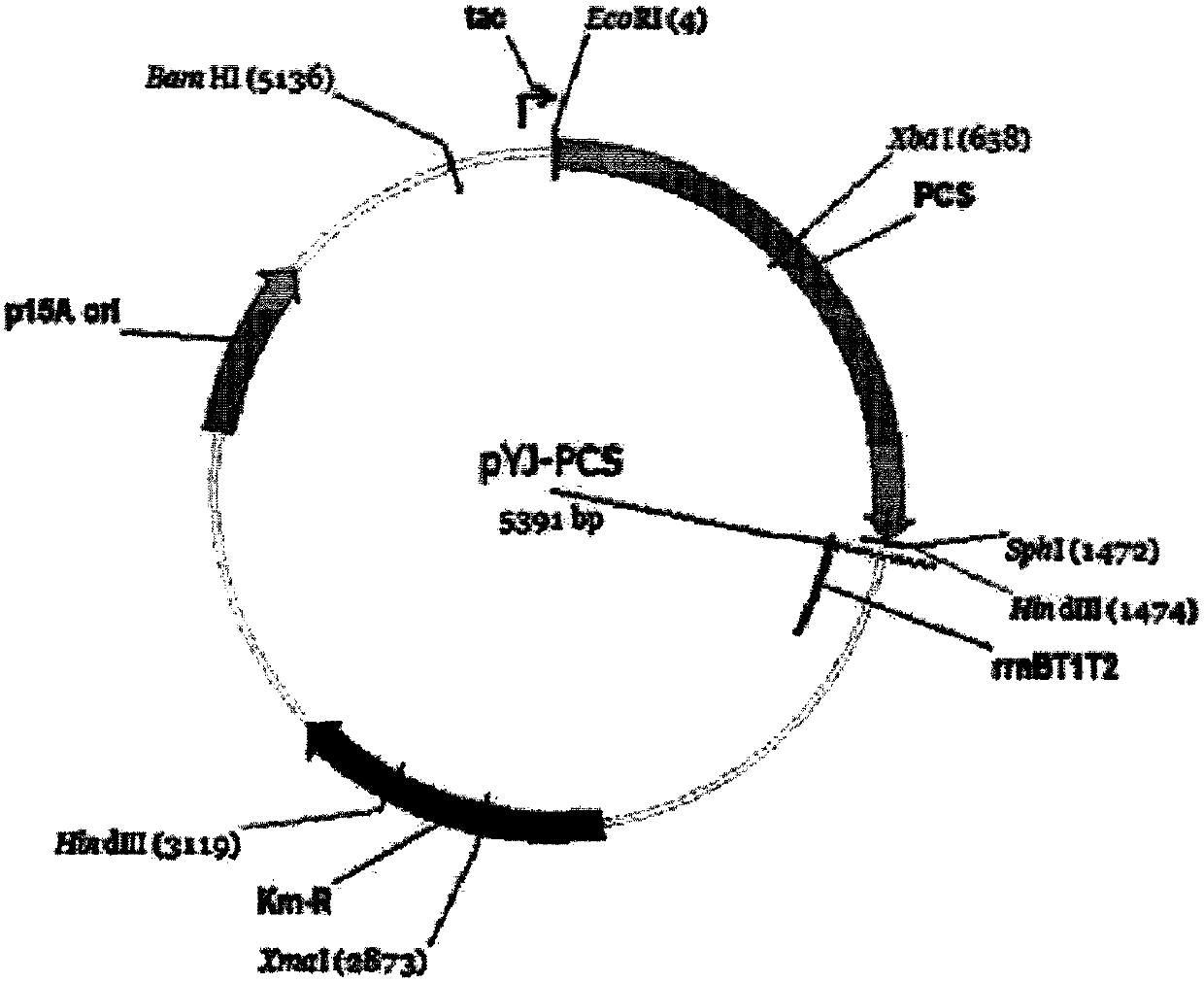

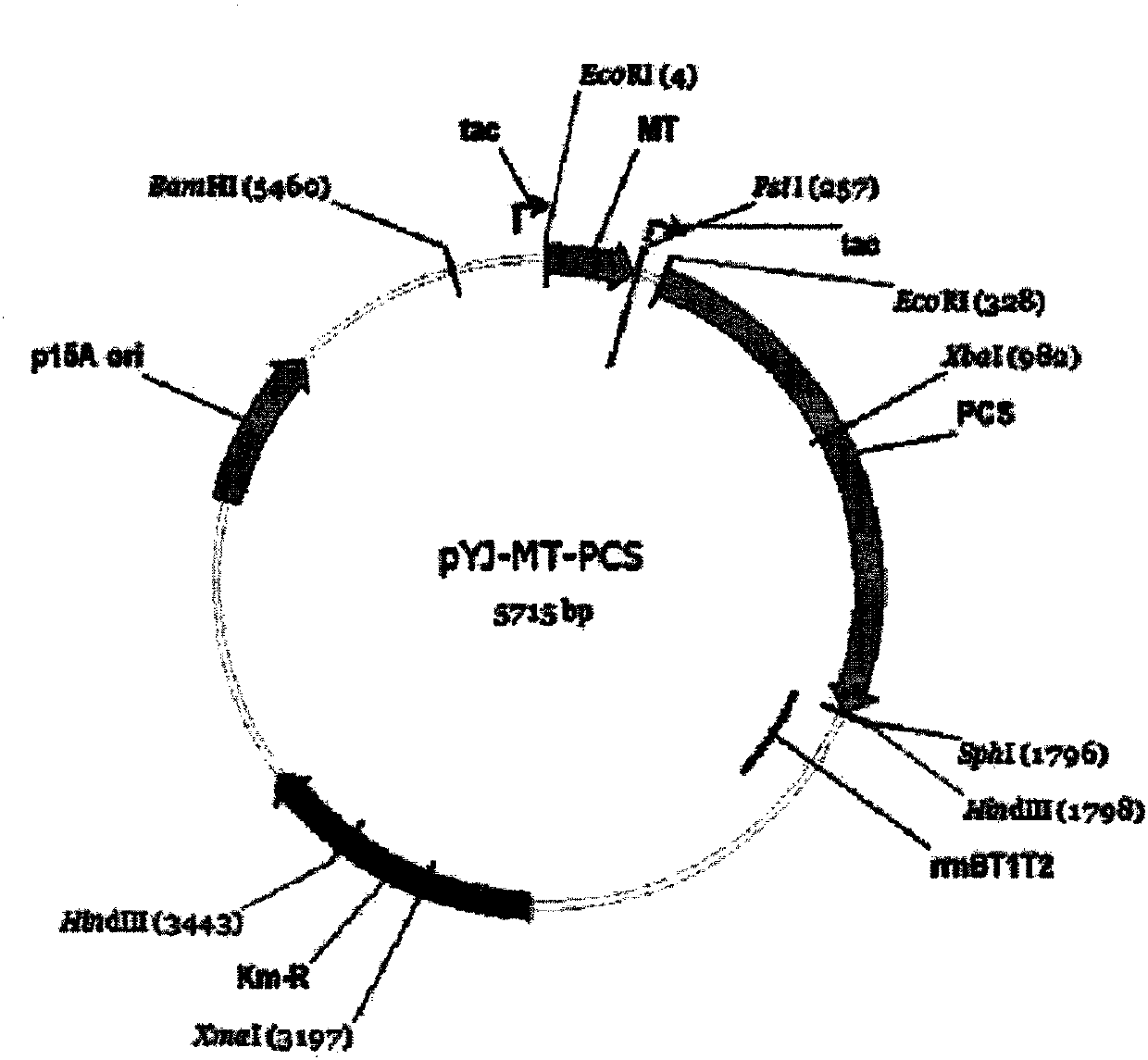

[0084] Embodiment 1: the expression load of co-expressing two kinds of heavy metal adsorption proteins (metallothionein and phytochelatin synthase) body construction

[0085] 1-1: Construction of metallothionein expression vector

[0086] Using the genomic DNA of Pseudomonas putida (Pseudomonas putida) KT2440 as a template, the primers of SEQ ID NO: 3 and 4 were used to carry out polymerase chain reaction (PCR), thereby constructing the nucleotide sequence encoding metallothionein (MT) The metallothionein (MT) gene fragment.

[0087] SEQ ID NO:3:5'-ATAGAATTCATGAACGATCACCACCACCACAAC-3'

[0088] SEQ ID NO:4:5'-TATCTGCAGTTAGGGCGAGATCGGATCACTC-3'

[0089] Next, the constructed metallothionein fragment was subjected to agarose gel electrophoresis to separate the 243-bp metallothionein gene fragment, which was then digested with two restriction enzymes (EcoRI and PstI). Simultaneously, the inducible pTac15K plasmid containing the tac promoter was digested with two restricti...

Embodiment 2

[0102] Example 2: Synthesis and Characterization of Elemental Metal Nanoparticles Using Recombinant Microorganisms

[0103] 2-1: Synthesis of elemental metal nanoparticles using recombinant microorganisms

[0104] One hour after induction of expression of metallothionein and phytochelatin synthase in the recombinant microorganisms produced in Example 1 above by IPTG, barium (Ba, (CH 3 COO) 2 Ba, 0.5mM), zirconium (Zr, K 2 ZrF 6 , 0.5mM), molybdenum (Mo, Na 2 MoO 4 2H 2 O, 0.5mM), indium (In, InCl 2 4H 2 O, 0.5mM), tin (Sn, SnCl 2 4H 2 O, 0.5mM), lanthanum (La, La(NO 3 ) 3 6H 2 O, 0.5mM), cerium (Ce, Ce(NO 3 ) 3 6H 2 O, 0.5mM) or praseodymium (Pr, Pr(NO 3 ) 3 6H 2 (2, 0.5mM) has been added in the LB liquid culture medium (tryptone 10g / L, yeast extract 5g / L, NaCl 5g / L, pH 6.5) that has cultivated recombinant E. Incubate for 12 hours. The culture was centrifuged at 3500 rpm and 4°C for 15 minutes, after which time the supernatant was discarded and the E. c...

Embodiment 3

[0109] Example 3: Synthesis and Characterization of Metal Alloy Nanoparticles Using Recombinant Microorganisms

[0110] 3-1: Synthesis of metal alloy nanoparticles using recombinant microorganisms

[0111] One hour after induction of expression of metallothionein and phytochelatin synthase by IPTG in the recombinant microorganism produced in Example 1 above, i) cobalt and iron (Co, CoCl 2 ,0.5mM, Fe, Fe(NO) 3 ·6H2 O, 0.5mM), ii) nickel and iron (Ni, NiCl 2 ·6H 2 O, 0.5mM, Fe, Fe(NO) 3 ·6H 2 O, 0.5mM), iii) zinc and manganese (Zn, ZnSO 4 ·7H 2 O, 0.5mM, MnCl 2 4H 2 O), 0.5mM, or iv) zinc and iron (Zn, ZnSO 4 ·7H 2 O, 0.5mM, Fe, Fe(NO) 3 ·6H 2 (2, 0.5mM) ions are added in the LB liquid culture medium (tryptone 10g / L, yeast extract 5g / L, NaCl5g / L, pH 6.5) that has cultivated recombinant escherichia coli bacterial strain, after this this recombinant microorganism is additionally Incubate for 12 hours. The culture was centrifuged at 3500 rpm and 4°C for 15 minutes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com