Safety device for motor vehicle having rotary latch and ejection spring

A technology of a safety device and a rotating lock fork, which is applied in the field of safety devices, can solve the problems of large structural space, increased total weight of a motor vehicle lock, etc., and achieves the effects of compact design, reduced noise emission, and reduced structural space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

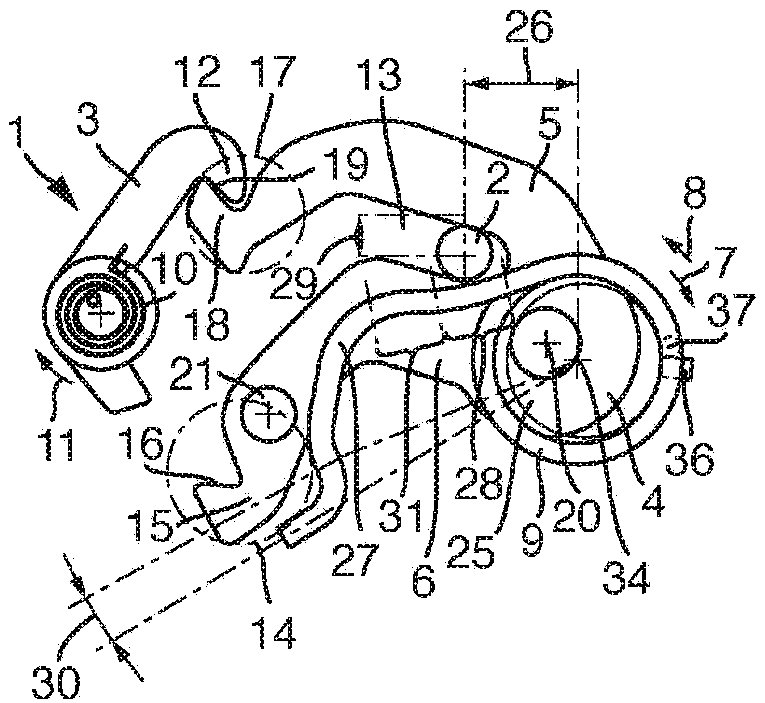

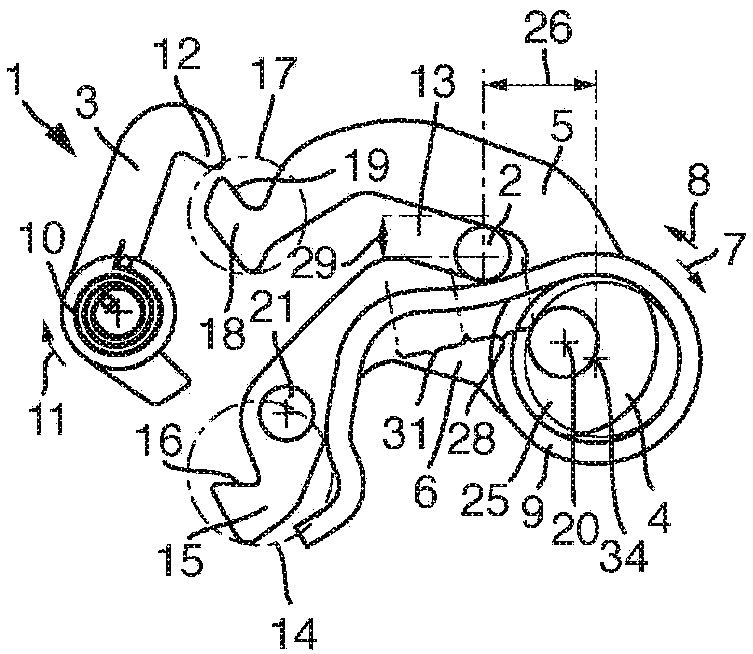

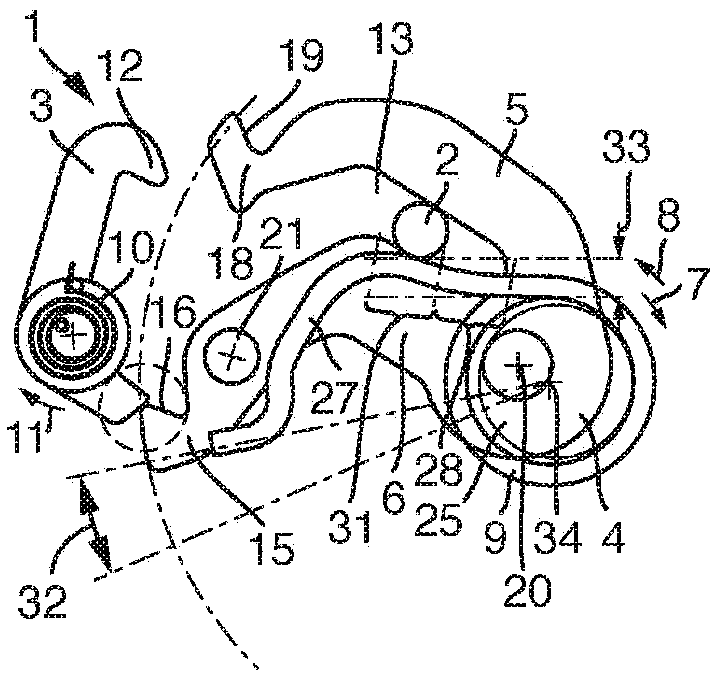

[0039] Figures 1a to 1f with Figures 2a to 2b The motor vehicle safety device 1 is shown during opening. The safety device 1 has a bolt 2 , a pawl 3 and a rotary fork 4 . The rotary latch 4 has a load arm 5 , a catch arm 6 , an opening rotational direction 7 , a closing rotational direction 8 , a pre-locking position and a main locking position. The safety device 1 also has an ejection spring 9 for ejecting the latch 2 , which is tensioned in the closing rotational direction 8 of the rotary catch 4 and acts on the rotary catch 4 in the opening rotational direction 7 . The ejector spring 9 preferably has a fixed end 36 , which is supported on a stationary support 37 of the safety device 1 . The fixed end 36 advantageously extends to the bearing sleeve 25 and surrounds the bearing sleeve 25 in such a way that the fixed end 36 cannot move relative to the rotational axis 34 of the ejector spring 9 . The pawl 3 has a pawl spring 10 which acts on the pawl 3 in the locking rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com