Multi-cylinder piston engine

A piston engine, engine technology, applied in the direction of internal combustion piston engines, combustion engines, engine components, etc., to achieve the effect of lowering the center of gravity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

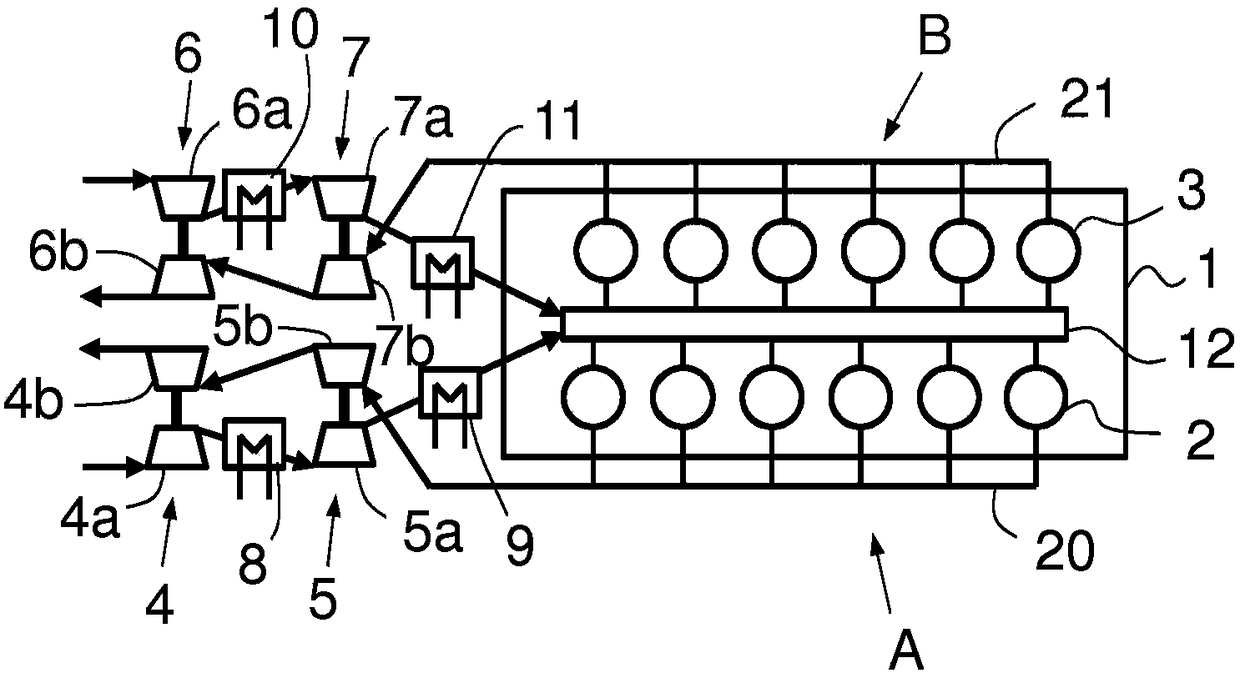

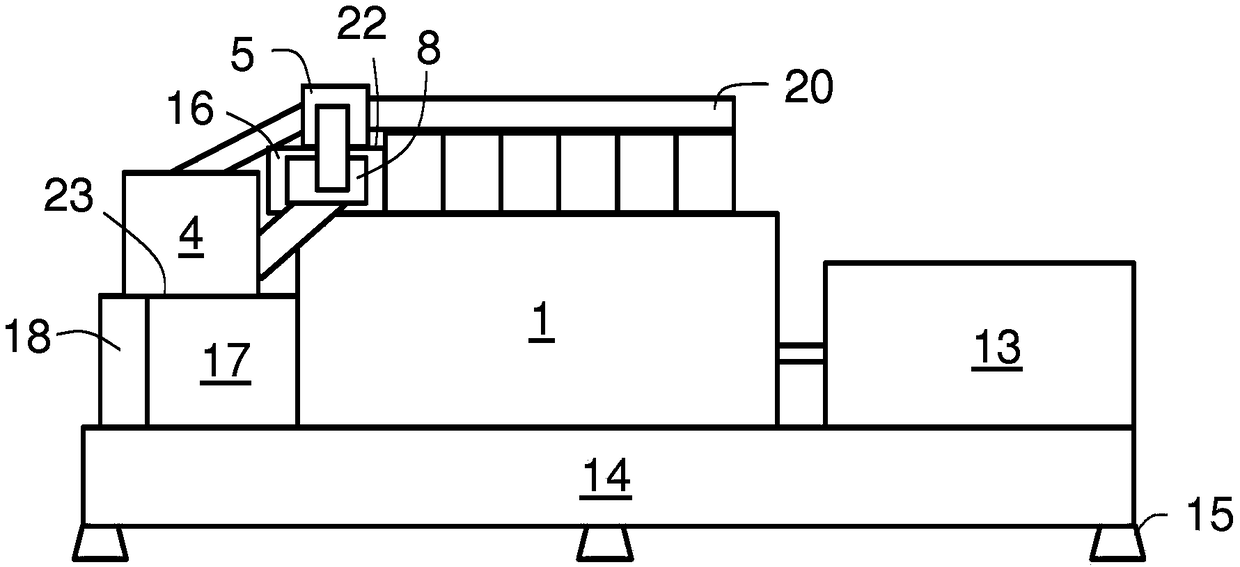

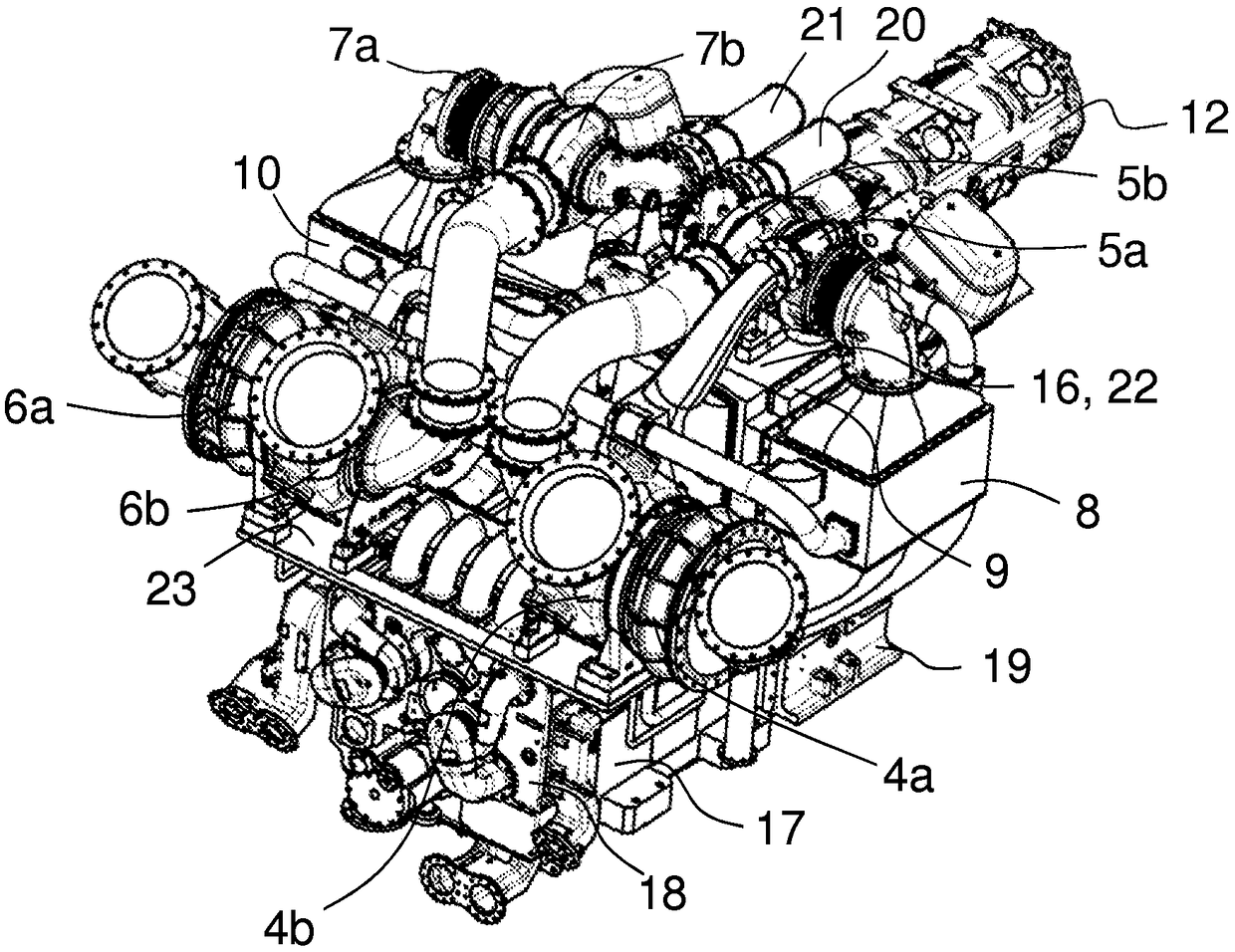

[0031] exist figure 2 , schematically shows figure 1 Side view of engine 1. According to a first embodiment of the invention, the engine 1 comprises a turbocharging system layout. From the direction of column A, engine 1 is shown. The engine 1 is arranged to drive a generator 13 . Engine 1 has a front end and a rear end. The generator 13 is coupled to the rear end of the engine 1 . Thus, the rear end is the flywheel end and drive end of the engine 1 . The front end is the free end. Instead of being coupled to a generator 13 , the engine 1 may be arranged to drive eg a propeller shaft of a ship. According to the invention, the turbochargers 4 , 5 , 6 , 7 of the engine 1 are arranged at the free end of the engine 1 . exist figure 2In , only the turbochargers 4 and 5 on the A-row side of the engine 1 can be seen. The engine 1 and the generator 13 are arranged on the same underframe 14 . The underframe 14 is supported on a floor structure, a ship hull or other similar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com