Single wavelength ellipsometry with improved spot size capability

A light beam and light collection technology, applied in the field of metering systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

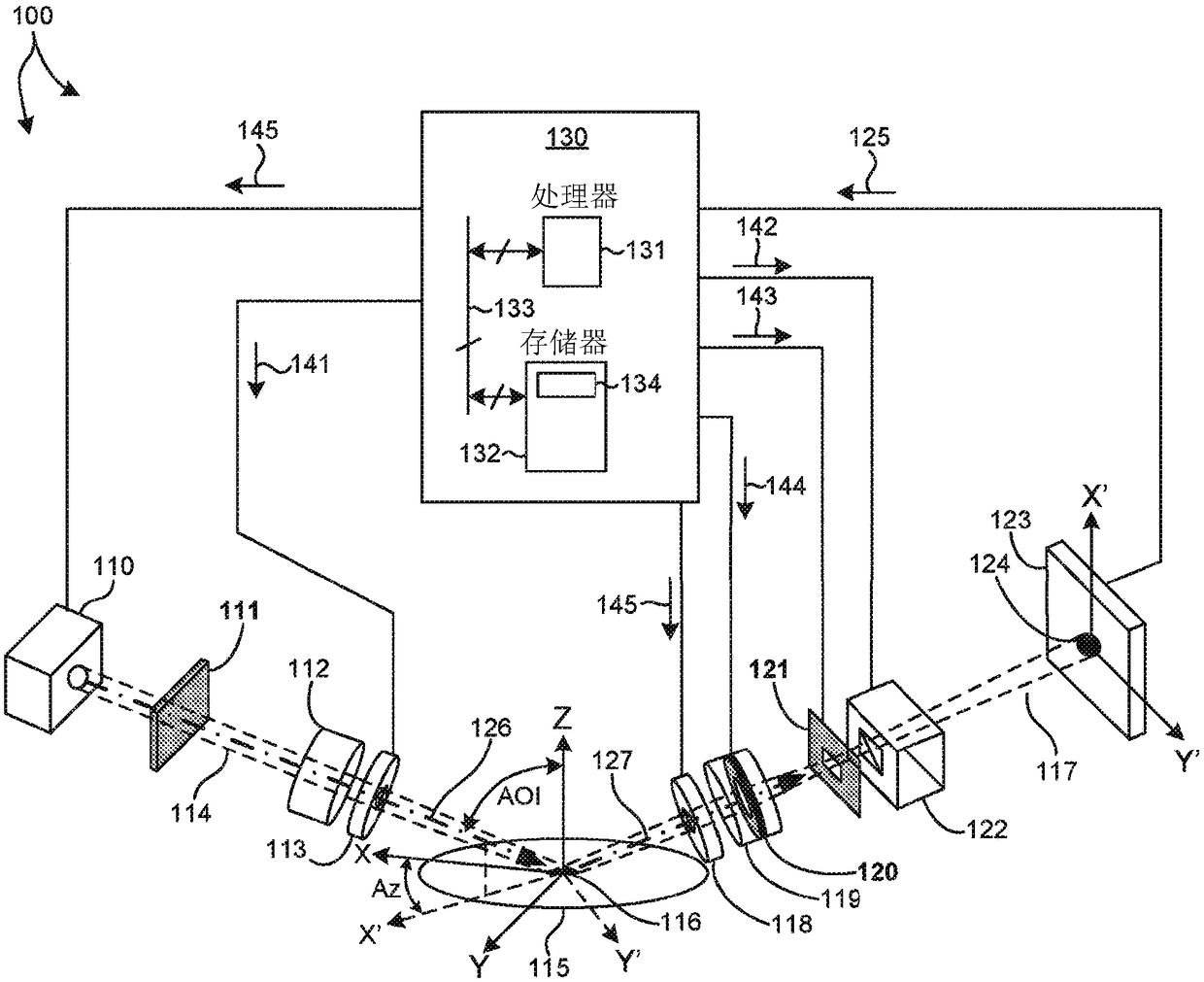

[0032] Reference will now be made in detail to background examples and some embodiments of the invention, examples of which are illustrated in the accompanying drawings.

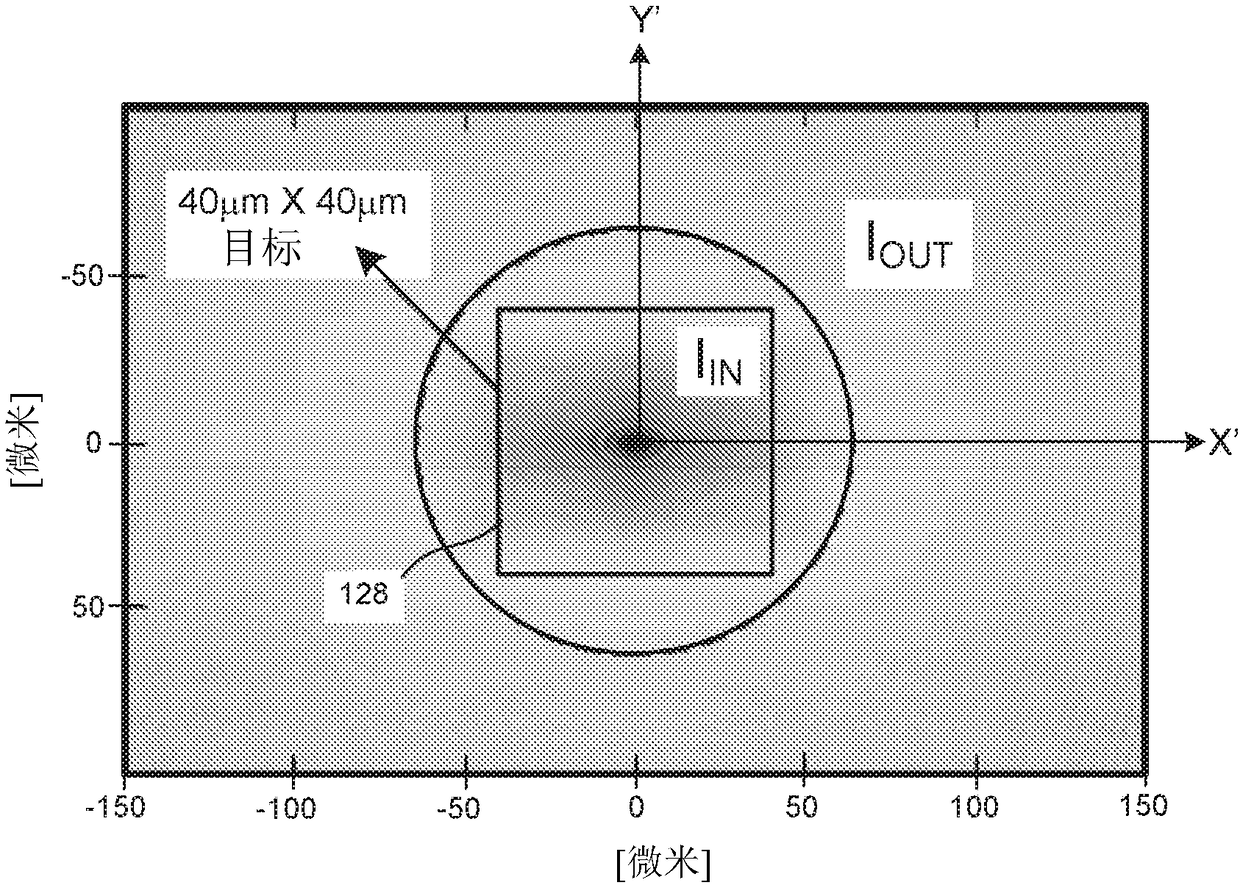

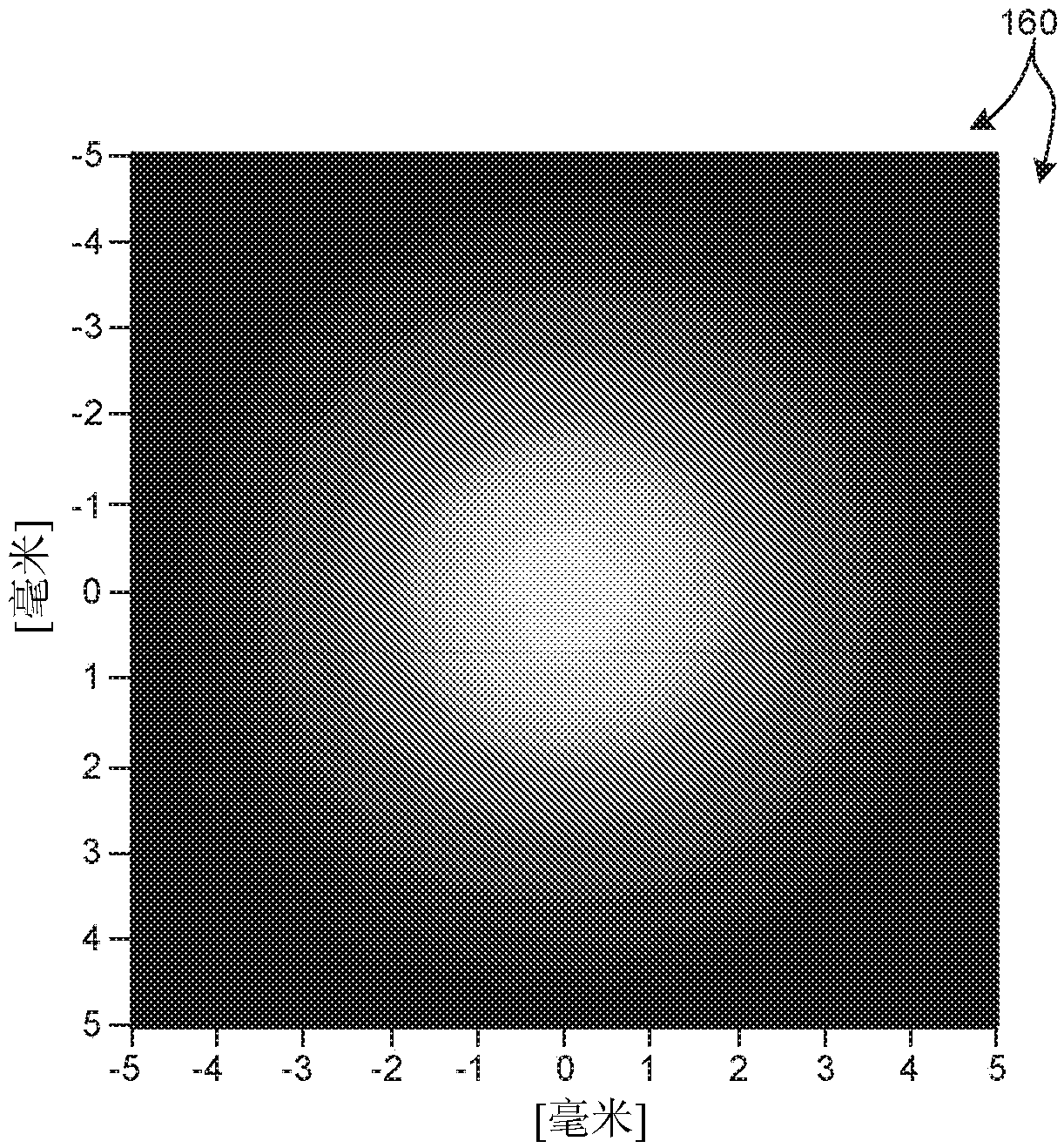

[0033] Presented herein are methods and systems for performing single wavelength ellipsometry (SWE) measurements with reduced measurement spot size. The measurement spot size reduction is achieved by the inclusion of: 1) a pupil stop located in the collection optical path at a position close to the pupil plane of the SWE system; 2) a field stop located close to the SWE In the collection optical path at the location of the image plane conjugate to the wafer plane of the system; 3) a linear polarizer comprising a thin, high extinction ratio, nanoparticle-based polarizer element located in the SWE system in the illumination path between the illumination source and the wafer; or any combination thereof. Reducing the measurement spot size will allow for more accurate thin film measurements and enhanced tool-to-t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com